High-efficiency isolating and sealing device for optical cable

A sealing device and optical cable technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of poor sealing performance and inconvenience, and achieve the effects of improved sealing performance, firm and reliable fixing, and a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

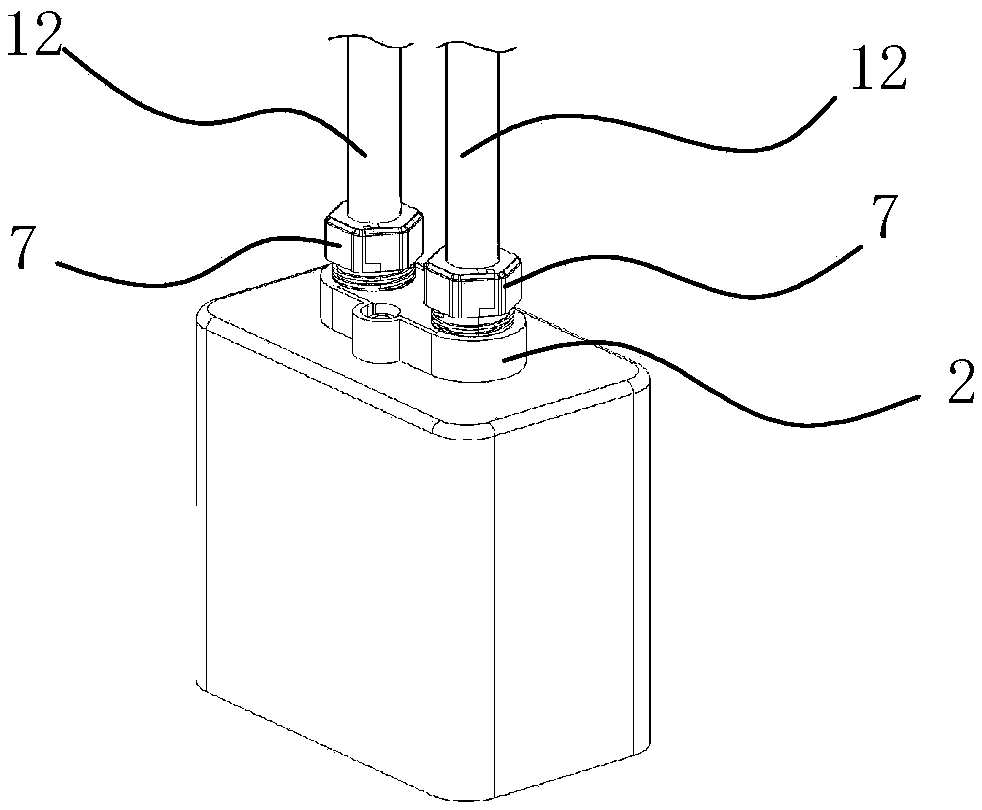

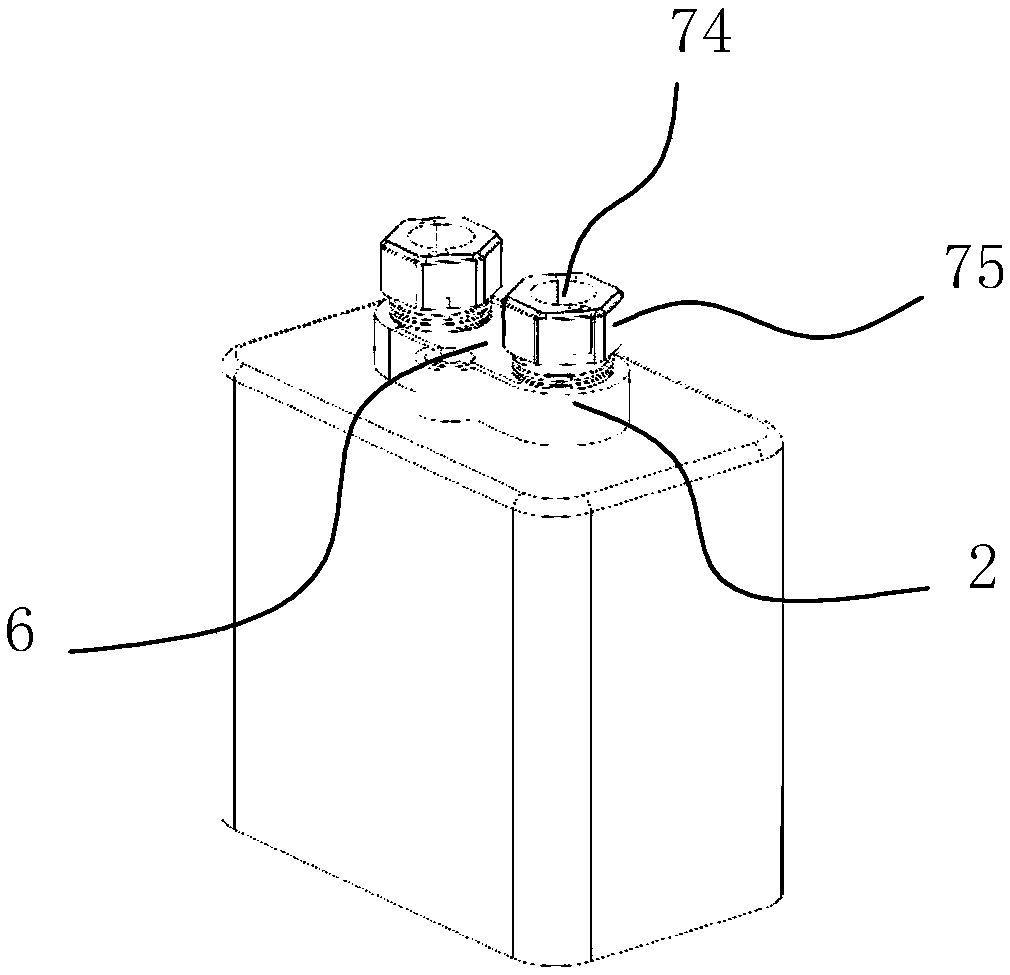

[0038] see Figure 1-Figure 9 , The high-efficiency isolation and sealing device for optical cables in this embodiment includes a sealing body 2 , a flexible sealing ring 42 , an extrusion ring 5 , an isolator 6 , a screw locking member 7 , a flexible limiting plate 41 , and a spacer 3 .

[0039] The extrusion ring 5 is composed of two semicircular extrusion petals 51 .

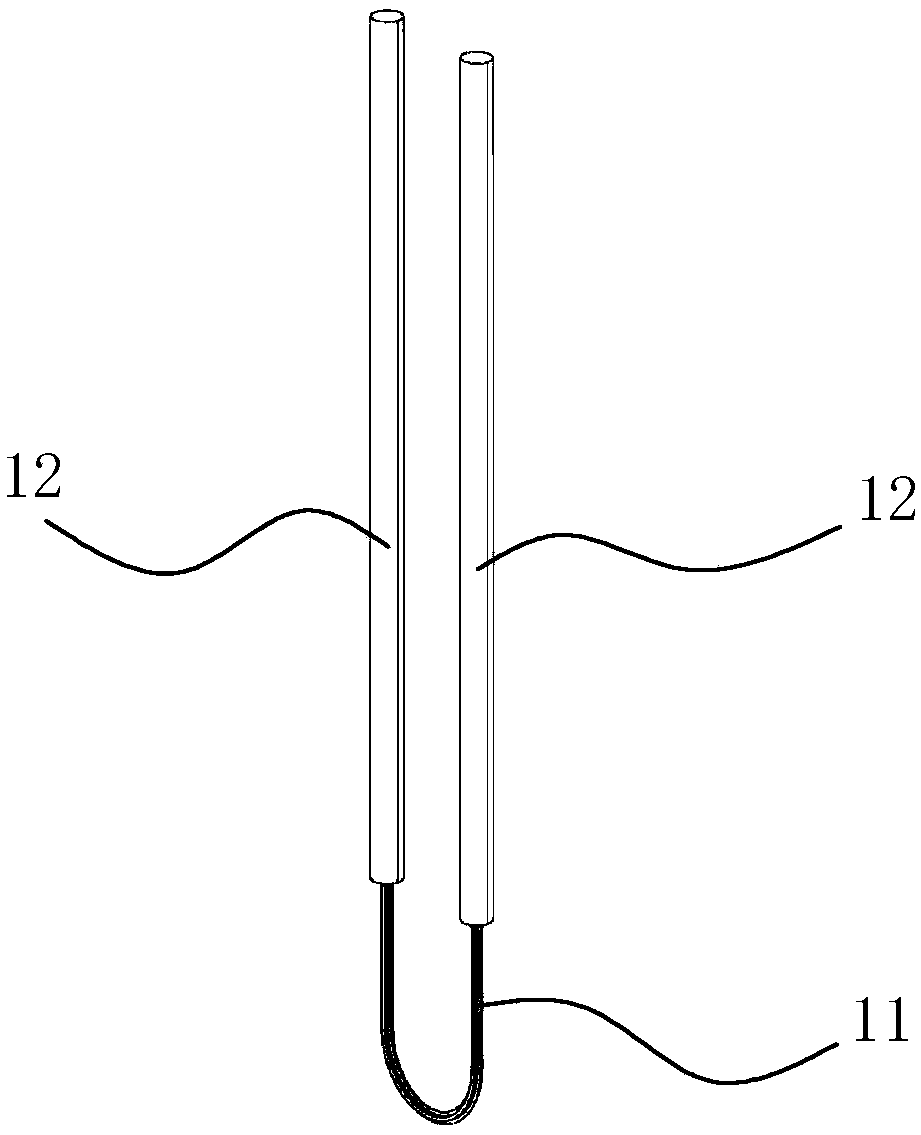

[0040] The sealing body 2 is provided with a sealing cavity 21 through which the U-shaped end 11 of the optical cable passes through.

[0041] The inner end of the sealing cavity 21 has a flexible limiting plate 41 against the flexible sealing ring 42, and the inner end wall of the sealing cavity 21 is integrally extended with a limiting edge 23 for resisting the flexible limiting plate 41, limiting The middle part of the bit edge 23 is provided with a spacer groove 24, and the spacer 3 is snapped into the spacer groove 24, and the side surface of the spacer 3 is flush with the side surface of the spacer edg...

Embodiment 2

[0054] see Figure 11-Figure 15 The high-efficiency isolation and sealing device for optical cables of this embodiment is basically the same as that of Embodiment 1, the difference being that: both the spacer 6 and the sealing body 2 extend outwards with a semicircular extension piece 9, and the outer convex side of the extension piece 9 is provided with Half thread structure 81, the groove 73 of the first locking part 71 and the groove 73 of the second locking part 72 all have a half thread structure 81, the half thread structure 81 of the first locking part 71 and the second The half-thread structure 81 of the locking portion 72 is combined to form the fastening thread section 82 .

[0055] The high-efficiency isolation and sealing device for optical cables in this embodiment can also be provided with two extrusion rings as described in Embodiment 1 (ie, a composite extrusion ring structure) in each sealing channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com