Automatic tool disassembling equipment for carrier

A carrier and automatic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as manual feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

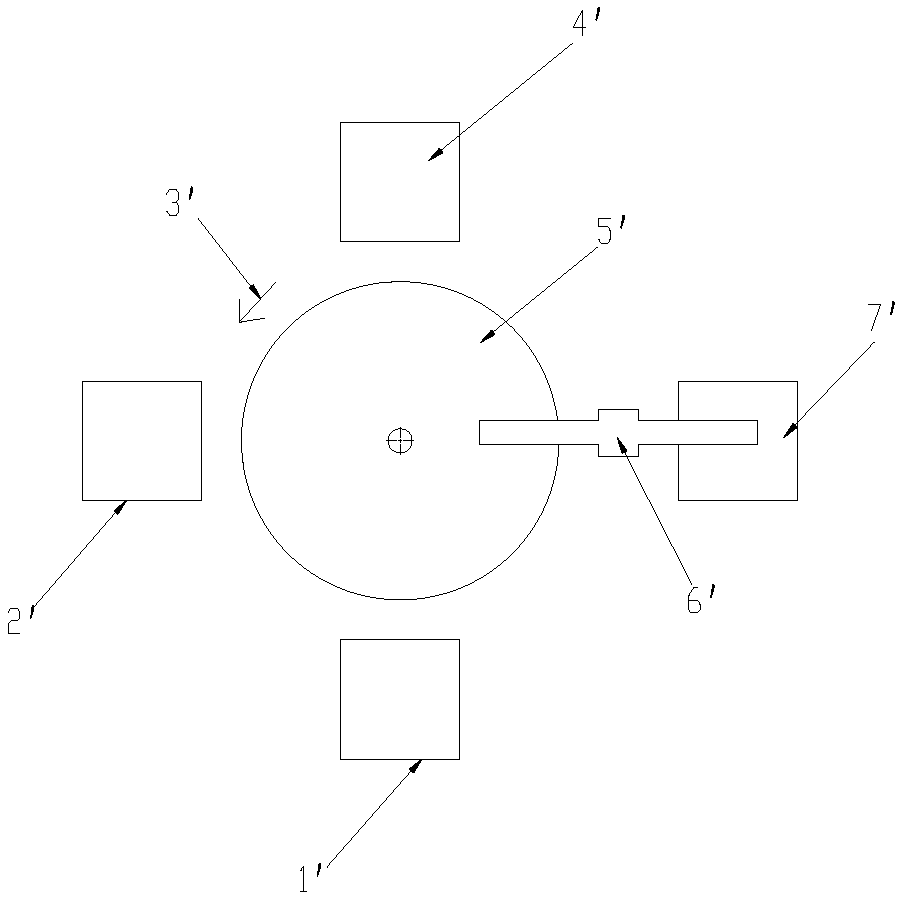

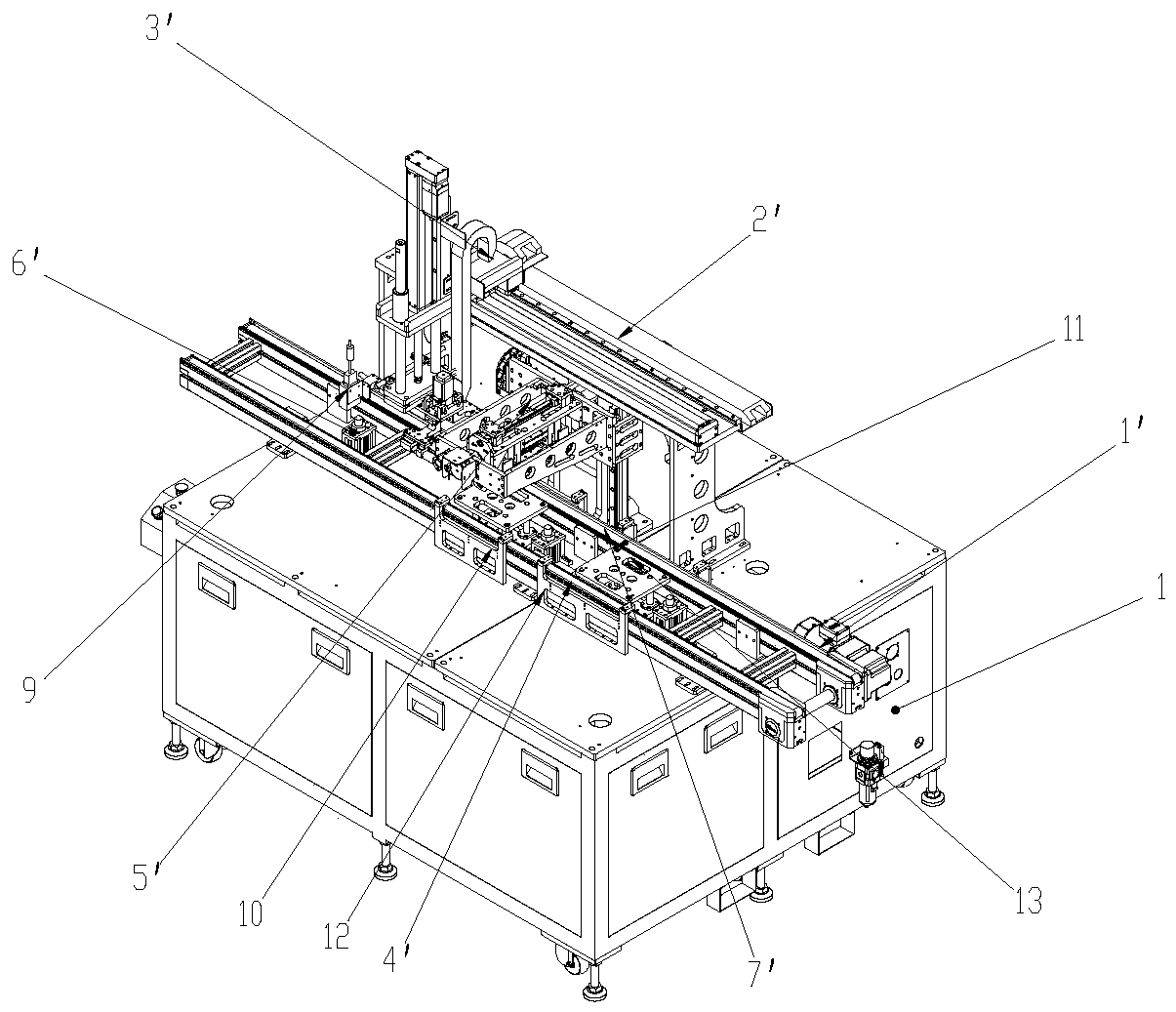

[0024] Such as image 3 As shown, the equipment for automatic disassembly and assembly of carriers of the present invention includes a transplanting and picking mechanism 3', a carrier turning mechanism 5', a blocking mechanism 13', a jacking mechanism 4' and a carrier conveying line mechanism 11 ', the transplanting pick-up mechanism 3' picks up the sub-carrier from the carrier turning mechanism 5', and the carrier conveying line mechanism 11' moves the carrier to the blocking mechanism 13' to block the carrier and the jacking mechanism 4' to lift the load With cooperation.

[0025] see image 3 and Figure 5 The transplanting and picking mechanism 3' includes a horizontal X-axis servo electric cylinder, a vertical Y-axis pick-up servo electric cylinder is arranged on the X-axis servo electric cylinder, and an electric gripper is installed on the top of the Y-axis pick-up servo electric cylinder. The electric claw is fixed with a gripper that matches the shape of the vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com