The method of suppressing high exhaust temperature of high pressure cylinder in fcb process

An exhaust temperature, high-pressure cylinder technology, applied in safety devices, machines/engines, mechanical equipment, etc., can solve the problems of unfavorable holding time for the unit to resume normal operation, discount of FCB effect, etc., to ensure safe and stable operation and improve reliability. , the effect of reducing uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in combination with the embodiments and accompanying drawings.

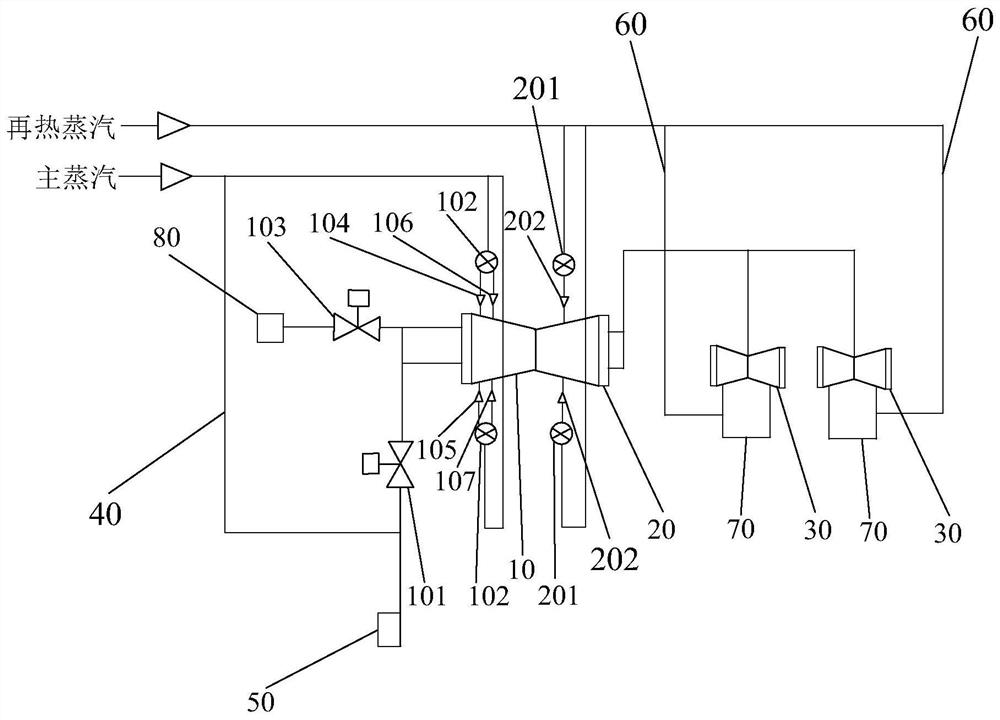

[0025] see figure 1 , the steam turbine of the embodiment of the present invention is a three-cylinder four-row steam turbine, including a high-pressure cylinder 10, a medium-pressure cylinder 20, and two low-pressure cylinders 30. When the FCB is running, the high-row check valve 101 is in a closed state. , the main steam is discharged to the reheat steam cold section main pipe 50 through the high pressure bypass 40, part of the reheat steam is discharged to the condenser 70 through the low pressure bypass 60, and part of the reheat steam enters the medium pressure through the medium pressure main steam valve 201 through the medium pressure regulating valve 202 Cylinder 20, to realize the steam production balance of the boiler (not shown in the fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com