Dynamic monitoring method for gas-liquid sealing performance of plunger gas-lift process

A dynamic monitoring and liquid sealing technology, which is applied in the directions of surveying, earthwork drilling and production, wellbore/well components, etc., can solve problems such as lifting failure, reduced fluid discharge, and reduced lifting efficiency, and achieves low monitoring cost and easy Easy to achieve and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is described in further detail below in conjunction with accompanying drawing:

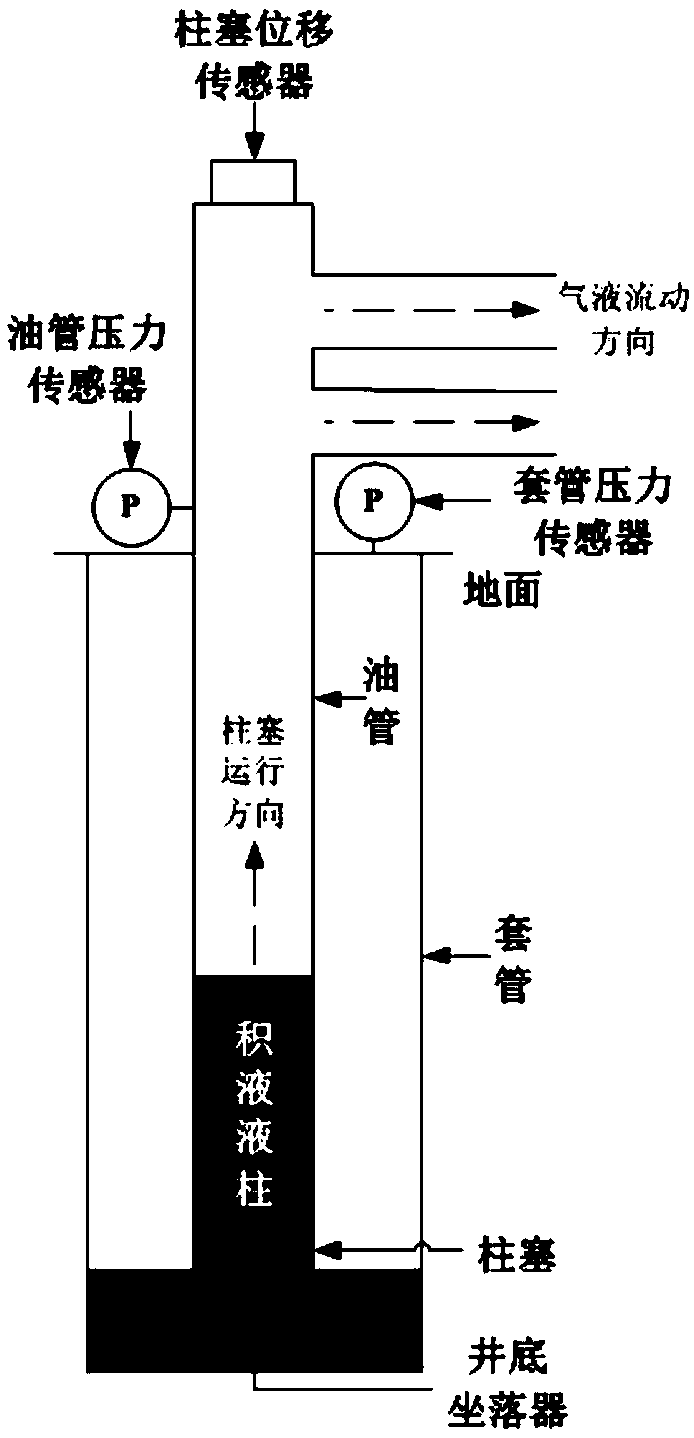

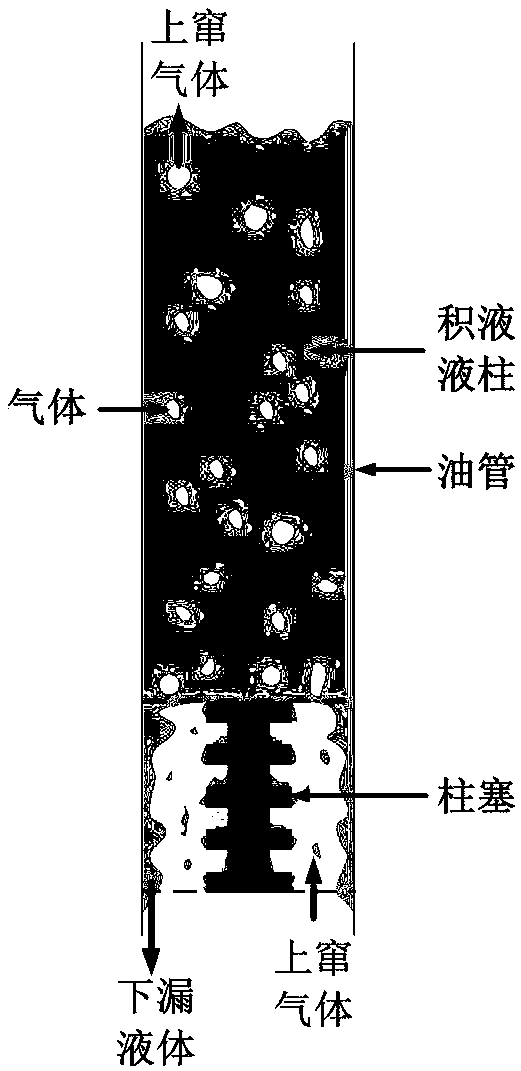

[0045] refer to Figure 1 to Figure 5 , the method for dynamic monitoring of gas-liquid sealing performance in the plunger gas lift process of the present invention comprises the following steps:

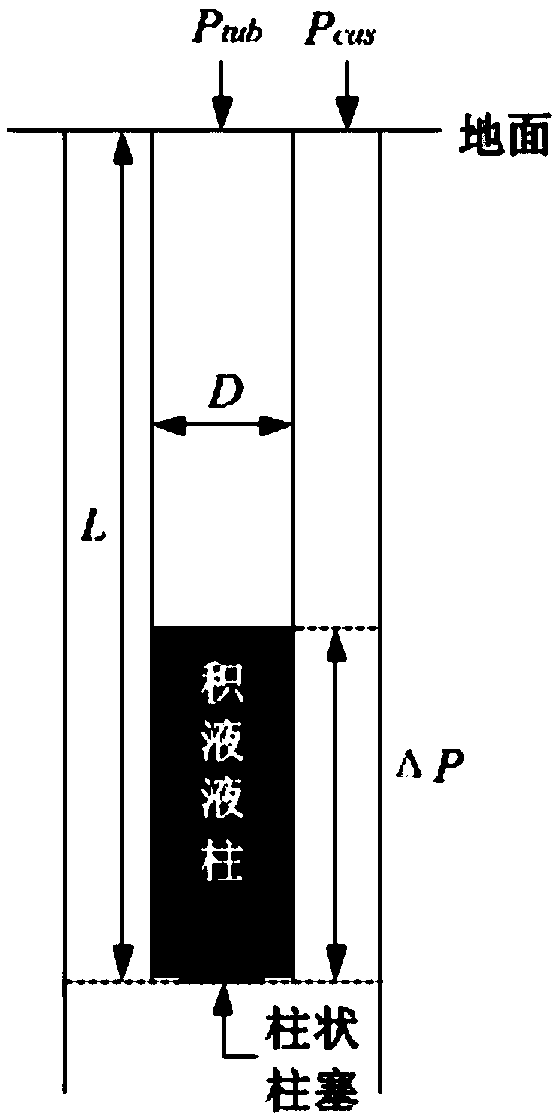

[0046] 1) Measure the dynamic pressure of the wellhead tubing through the wellhead pressure sensor and wellhead casing dynamic pressure Then according to the wellhead tubing pressure when the well is opened and lifted and wellhead casing pressure Calculating the mass of liquid column above the plunger when the well is opened and lifted Among them, the mass of the fluid column above the plunger when the well is opened and lifted for:

[0047]

[0048] Among them, L is the depth of the bottom hole seater, g is the acceleration of gravity, and D is the inner diameter of the tubing.

[0049] 2) According to the depth L of the bottom hole seater and the tubing pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com