Serial-parallel artificial wrist joint with three degrees of freedom

A parallel, wrist technology, applied in the field of artificial wrist joints, can solve the problems of complex structure and heavy weight, and achieve the effects of high precision, light weight and strong functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

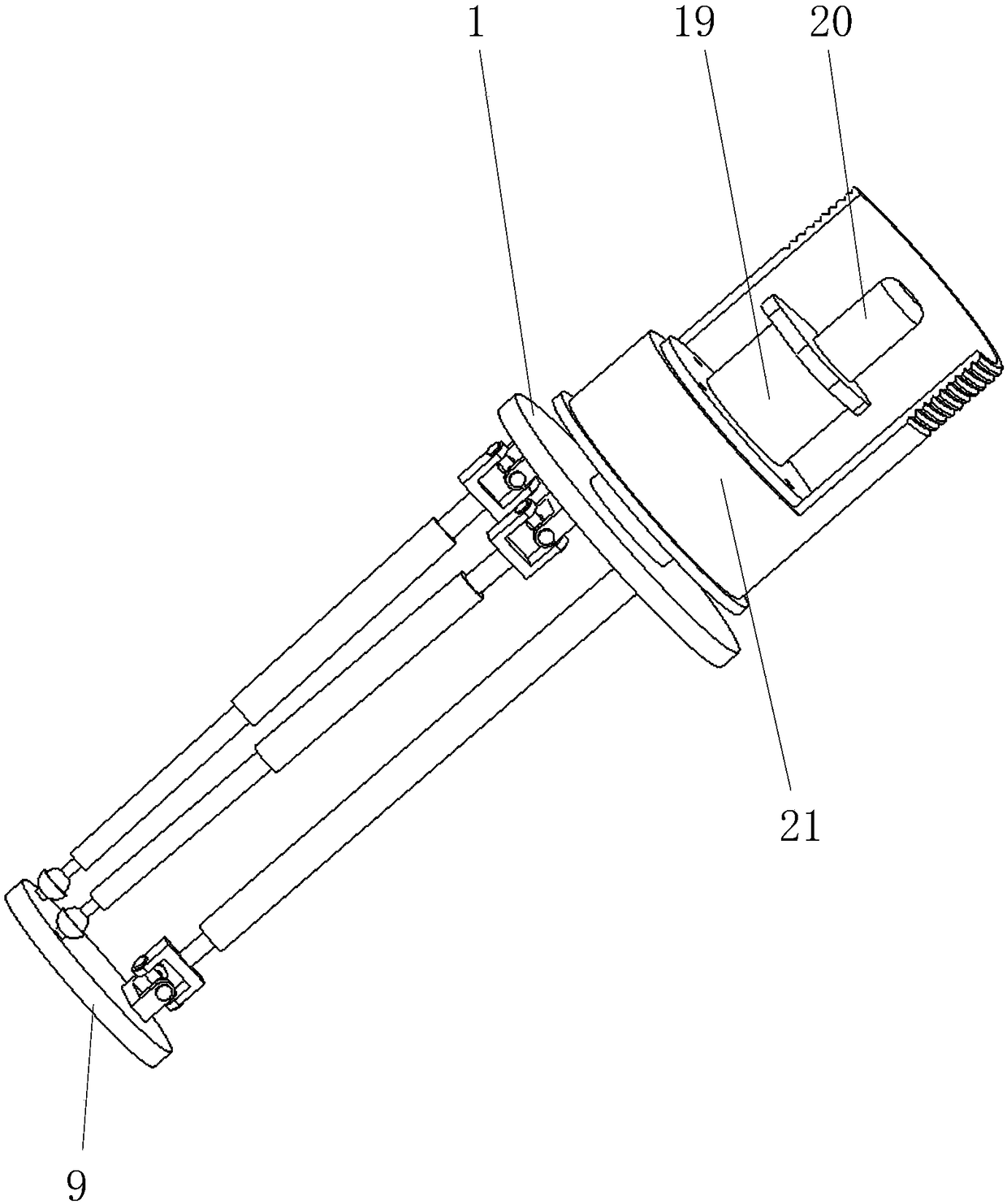

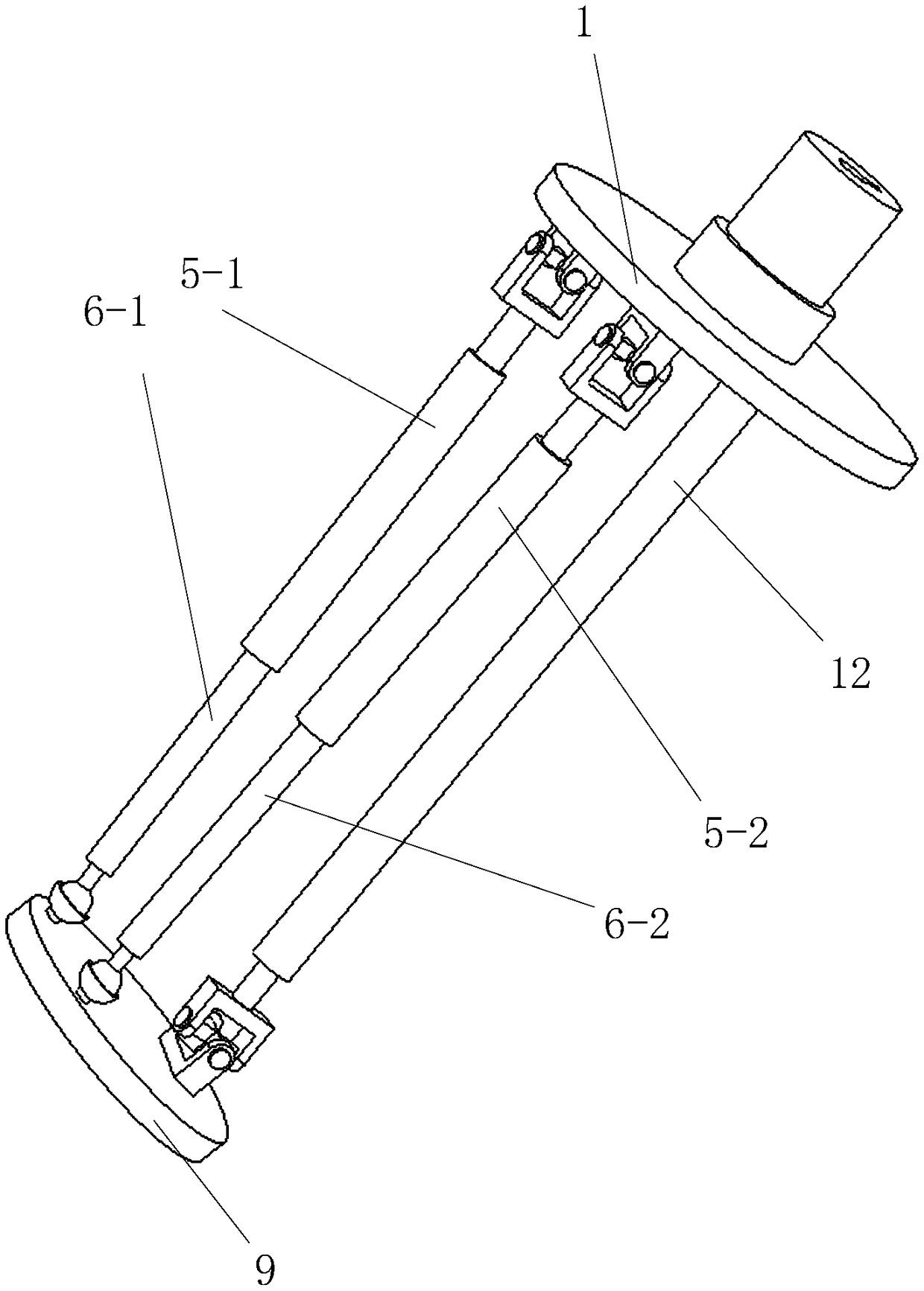

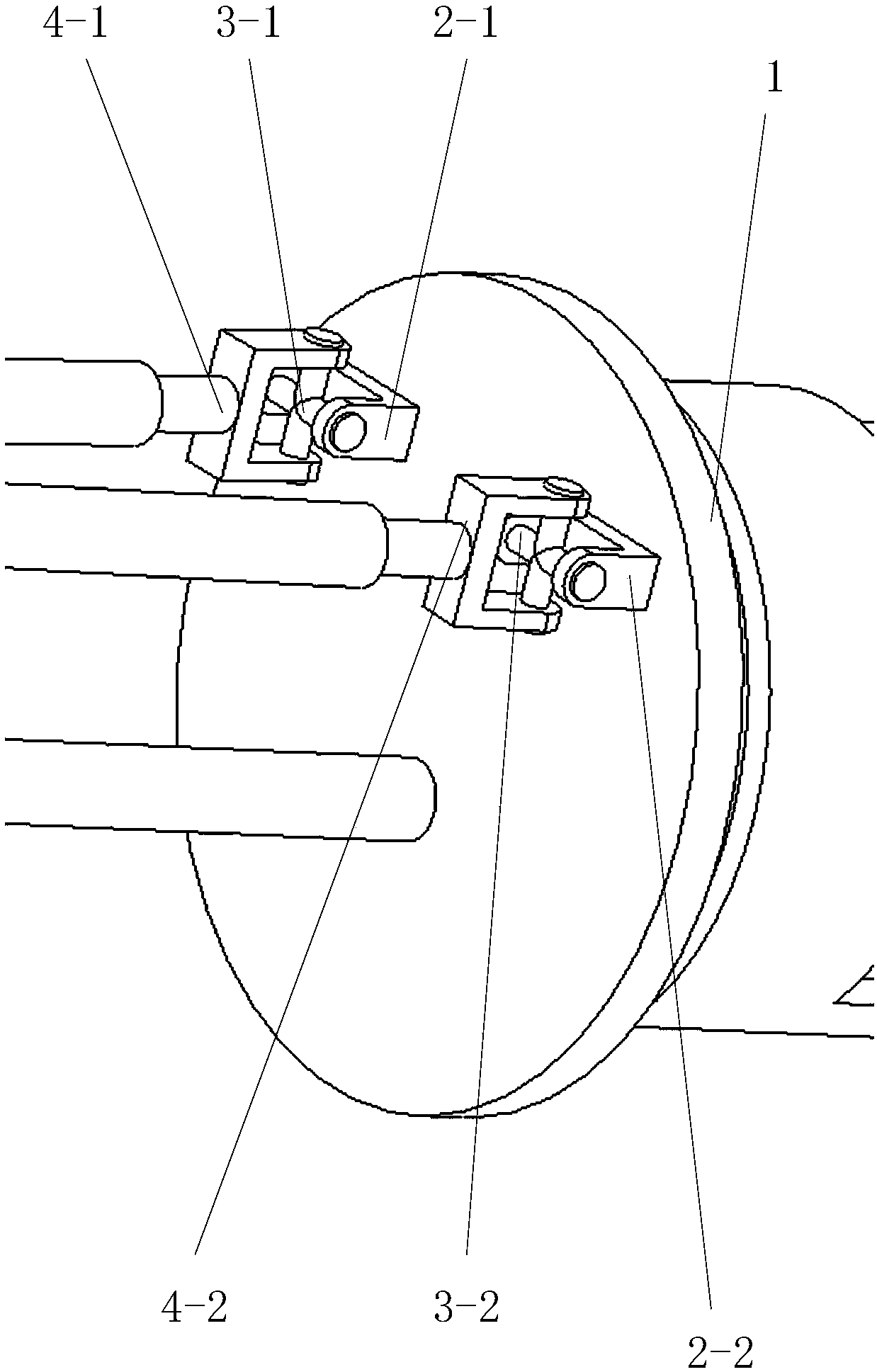

[0021] Such as Figure 1 to Figure 6 As shown, the present embodiment provides a three-degree-of-freedom parallel prosthetic wrist joint, including a base (21), a rotating table (1), a first active branch chain, a second active branch chain, a constraint branch chain, and a moving platform ( 9).

[0022] The rotary table (1) sequentially passes through the end cover (13), the first bearing (14), the bearing spacer (15), the second bearing (16), the C-shaped collar (17) and the motor (20) The output shaft is connected through a flat key (18), the motor (20) is fixedly connected to the base (21) through a reducer (19), and the rotating table (1) is equipped with a bearing spacer (15) and a C-shaped collar (17). , the bearing spacer (15) is placed between the two rolling bearings (14 and 16), and the C-shaped snap ring (17) is placed on the side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com