Tightly-woven stitch-set elevating and adjusting transmission structure

A technology of lifting adjustment and transmission structure, which is applied in the direction of weft knitting, knitting, textiles and papermaking, etc., can solve the problems of low working efficiency, poor adjustment accuracy and complex structure of the knitting machine head, and achieve simple mechanical structure, high precision, The effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

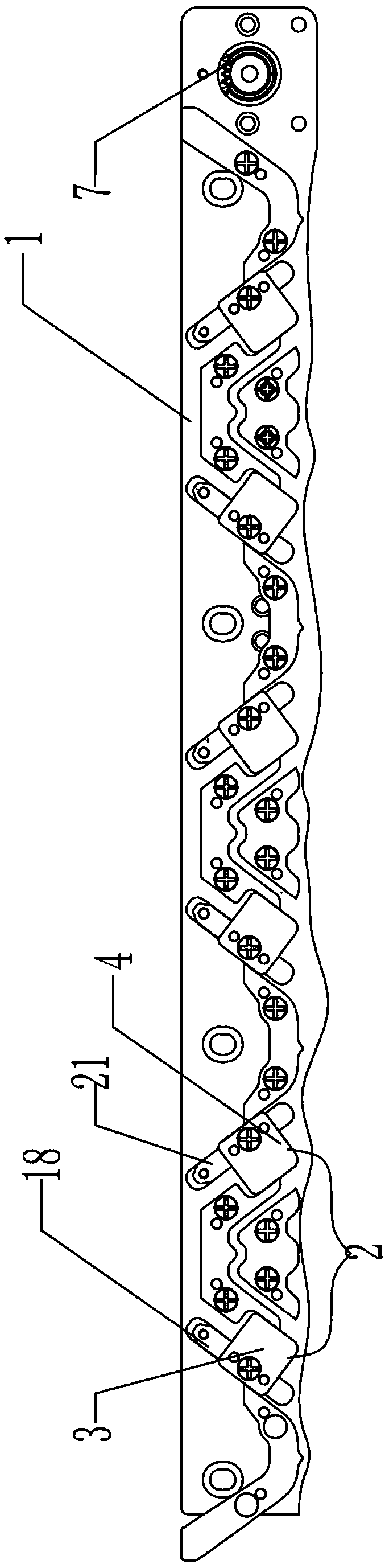

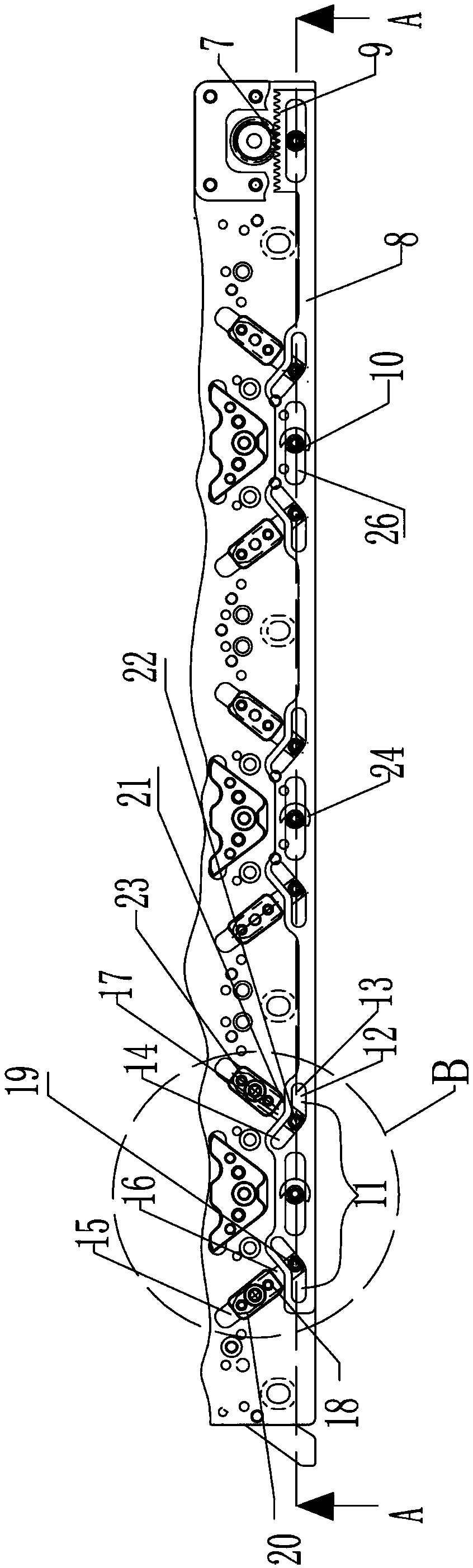

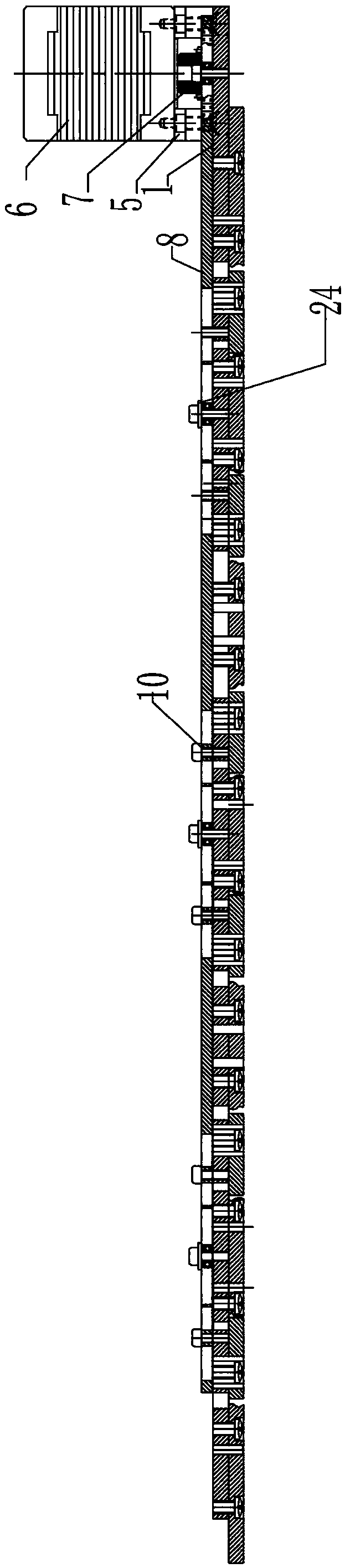

[0020] Such as Figure 1-8 As shown, the tight knitting stitch lifting adjustment transmission structure provided by this embodiment includes a base plate 1 for fixing each needle cam on the head of the flat knitting machine, and more than one set of double stitch cam units 2 are arranged on the front of the base plate 1 , each group of double stitch triangular unit 2 includes the left stitch triangular needle 3 and the right stitch triangular needle 4 which are mirror images of each other, and a stepping motor 6 is fixed on one side of the back of the base plate 1 through a motor seat 5, and the output of the stepping motor 6 The shaft is driven and connected with a gear 7, and an adjustment bar 8 extending in the same direction as the base plate 1 is provided on the back of the base plate 1. The side of one end of the adjustment bar 8 is provided with a toothed rack 9 meshing with the gear 7. The adjustment bar 8 8 is provided with more than one first flat groove 26 at inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com