Agricultural peanut drying equipment

A peanut and equipment technology, applied in the field of peanut drying equipment, can solve the problems of inconvenient collection of peanuts and inability to shelter from rain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

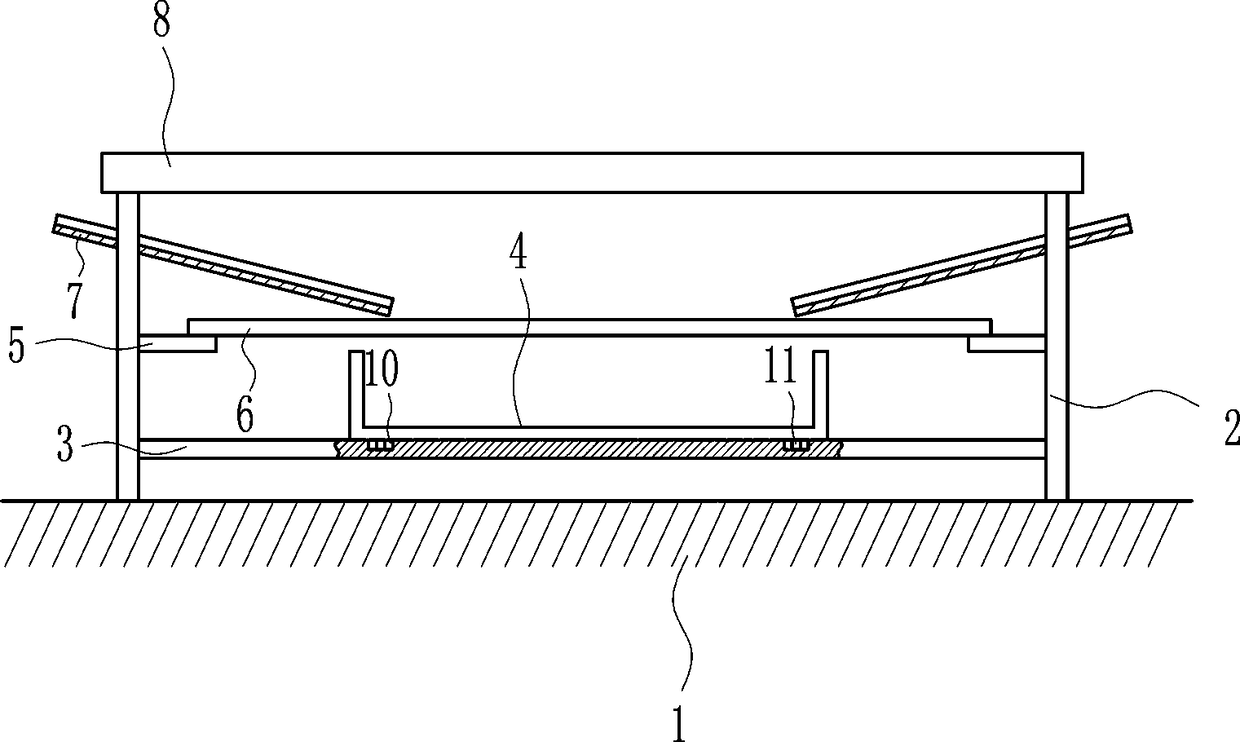

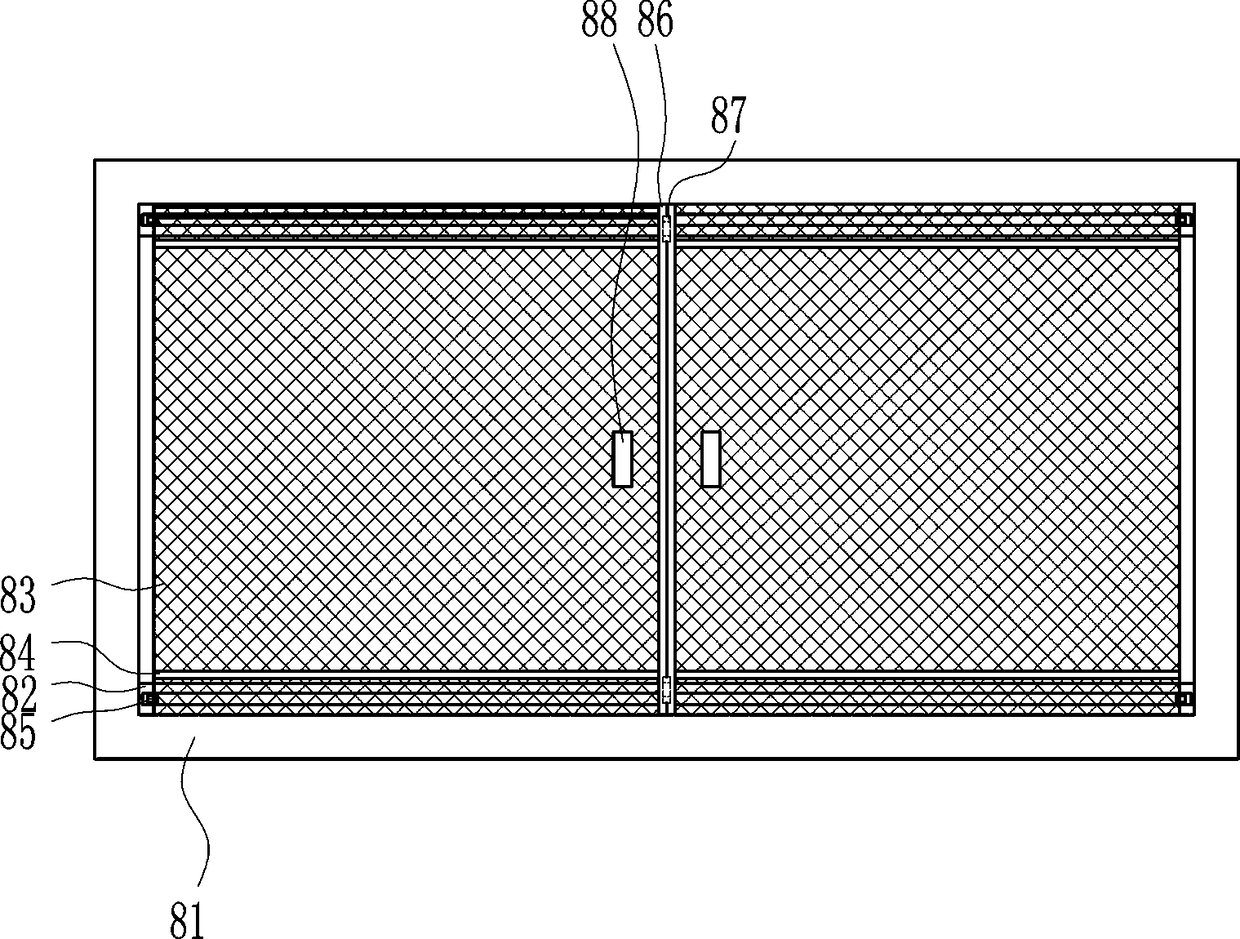

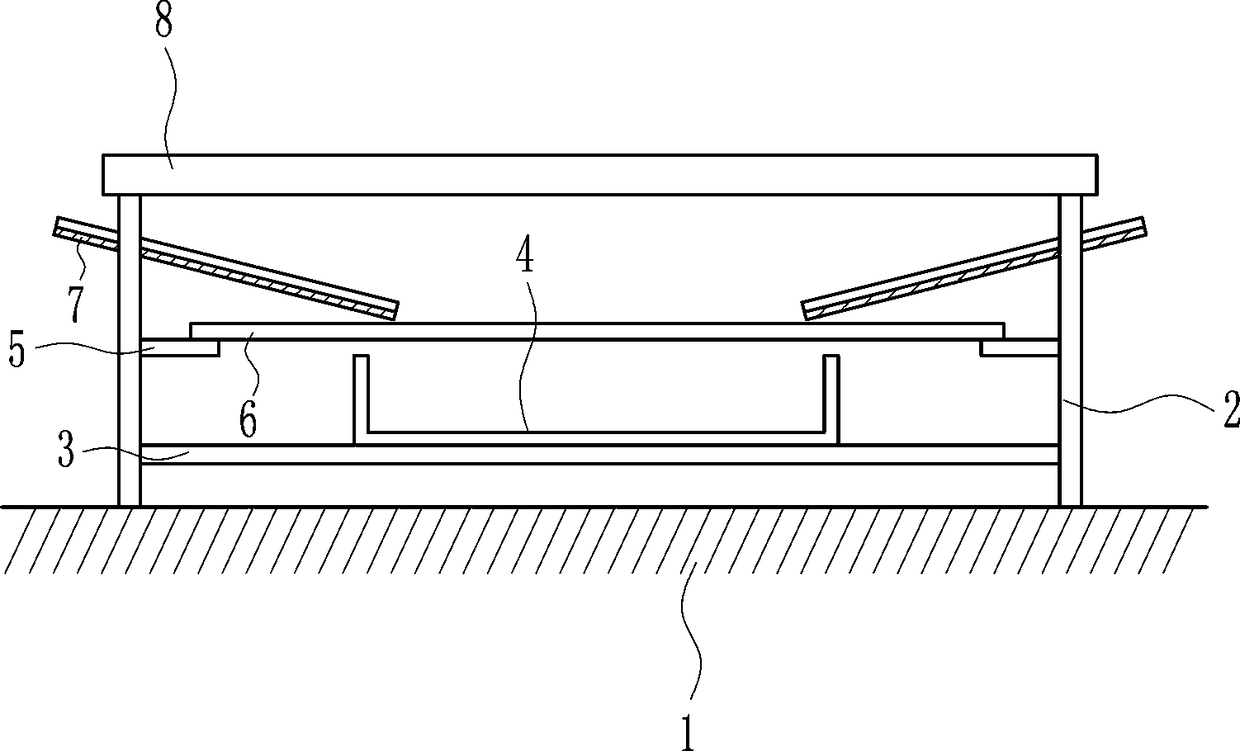

[0027] A peanut drying equipment used in agriculture, such as Figure 1-6As shown, it includes a first pole 2, a placement plate 3, a collection frame 4, a first baffle plate 5, a cover plate 6, a slideway 7 and a placement device 8, and the left and right sides of the ground 1 are provided with There is a first support rod 2, and the inner lower part of the first support rod 2 on the left and right sides is provided with a placement plate 3, and a collection frame 4 is placed in the middle of the top of the placement plate 3, and the right middle part of the two first support rods 2 on the left is All are provided with first baffle plate 5, and the left middle part of two first struts 2 on the right side is also provided with first baffle plate 5, and cover plate 6 is placed on the first baffle plate 5, left and right A slideway 7 is provided between the two first poles 2 on the front and rear sides, and the slideways 7 are all inclined inwardly, and a placement device 8 is p...

Embodiment 2

[0029] A peanut drying equipment used in agriculture, such as Figure 1-6 As shown, it includes a first pole 2, a placement plate 3, a collection frame 4, a first baffle plate 5, a cover plate 6, a slideway 7 and a placement device 8, and the left and right sides of the ground 1 are provided with There is a first support rod 2, and the inner lower part of the first support rod 2 on the left and right sides is provided with a placement plate 3, and a collection frame 4 is placed in the middle of the top of the placement plate 3, and the right middle part of the two first support rods 2 on the left is All are provided with first baffle plate 5, and the left middle part of two first struts 2 on the right side is also provided with first baffle plate 5, and cover plate 6 is placed on the first baffle plate 5, left and right A slideway 7 is provided between the two first poles 2 on the front and rear sides, and the slideways 7 are all inclined inwardly, and a placement device 8 is ...

Embodiment 3

[0032] A peanut drying equipment used in agriculture, such as Figure 1-6 As shown, it includes a first pole 2, a placement plate 3, a collection frame 4, a first baffle plate 5, a cover plate 6, a slideway 7 and a placement device 8, and the left and right sides of the ground 1 are provided with There is a first support rod 2, and the inner lower part of the first support rod 2 on the left and right sides is provided with a placement plate 3, and a collection frame 4 is placed in the middle of the top of the placement plate 3, and the right middle part of the two first support rods 2 on the left is All are provided with first baffle plate 5, and the left middle part of two first struts 2 on the right side is also provided with first baffle plate 5, and cover plate 6 is placed on the first baffle plate 5, left and right A slideway 7 is provided between the two first poles 2 on the front and rear sides, and the slideways 7 are all inclined inwardly, and a placement device 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com