Built-in sliding door lower guide rail installation structure

An installation structure, embedded technology, applied in the direction of doors, transportation and packaging, vehicle parts, etc., can solve the problems of reducing the rigidity of the whole vehicle and the collision level, and achieve the effect of ensuring the rigidity and increasing the distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

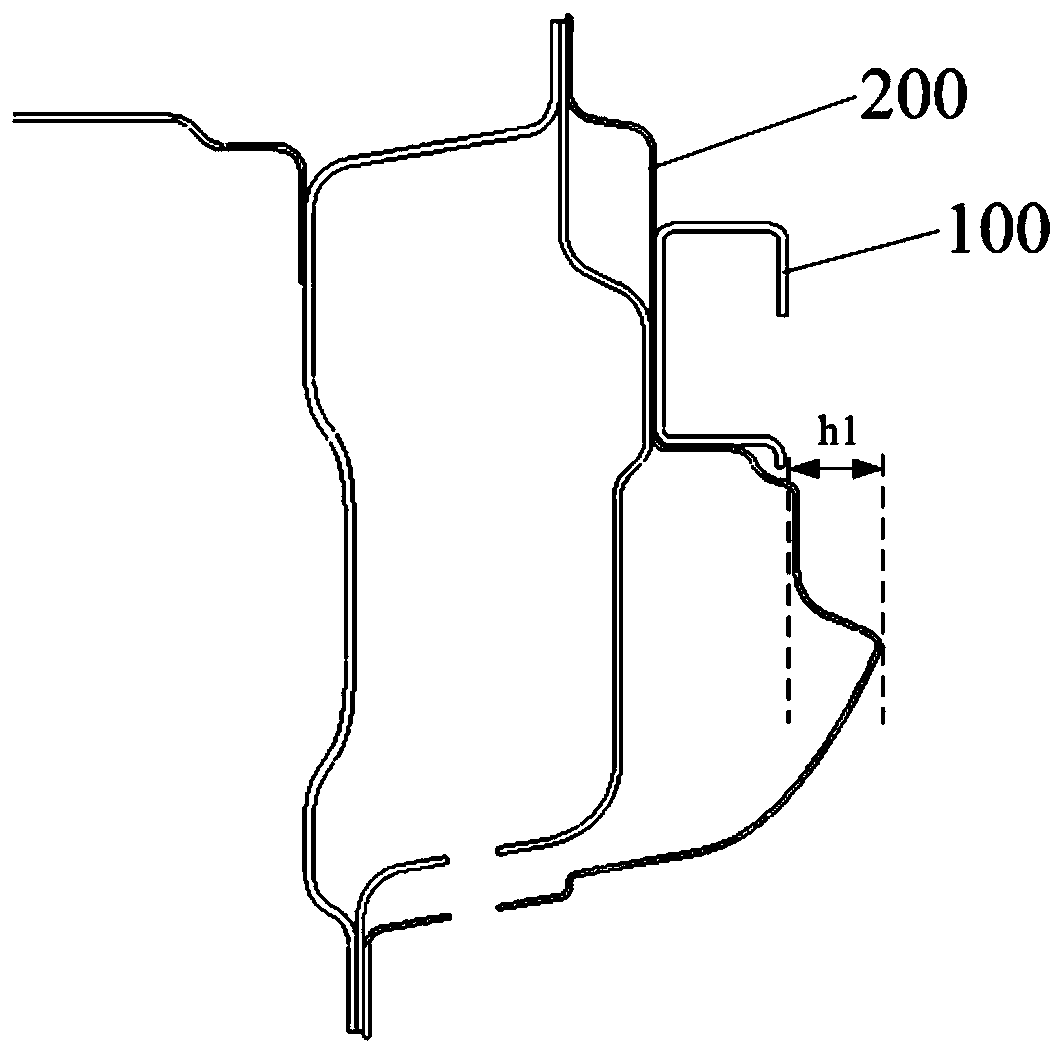

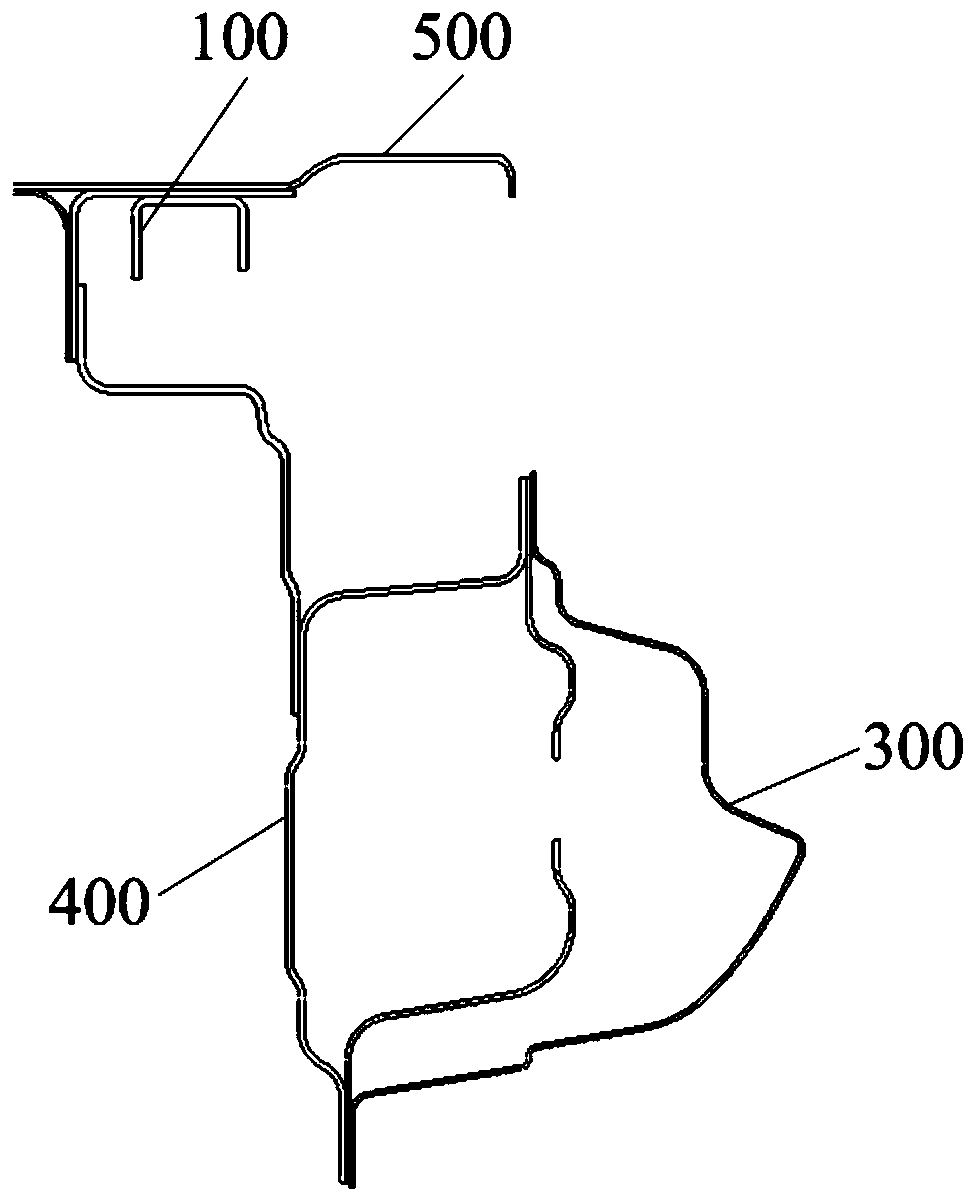

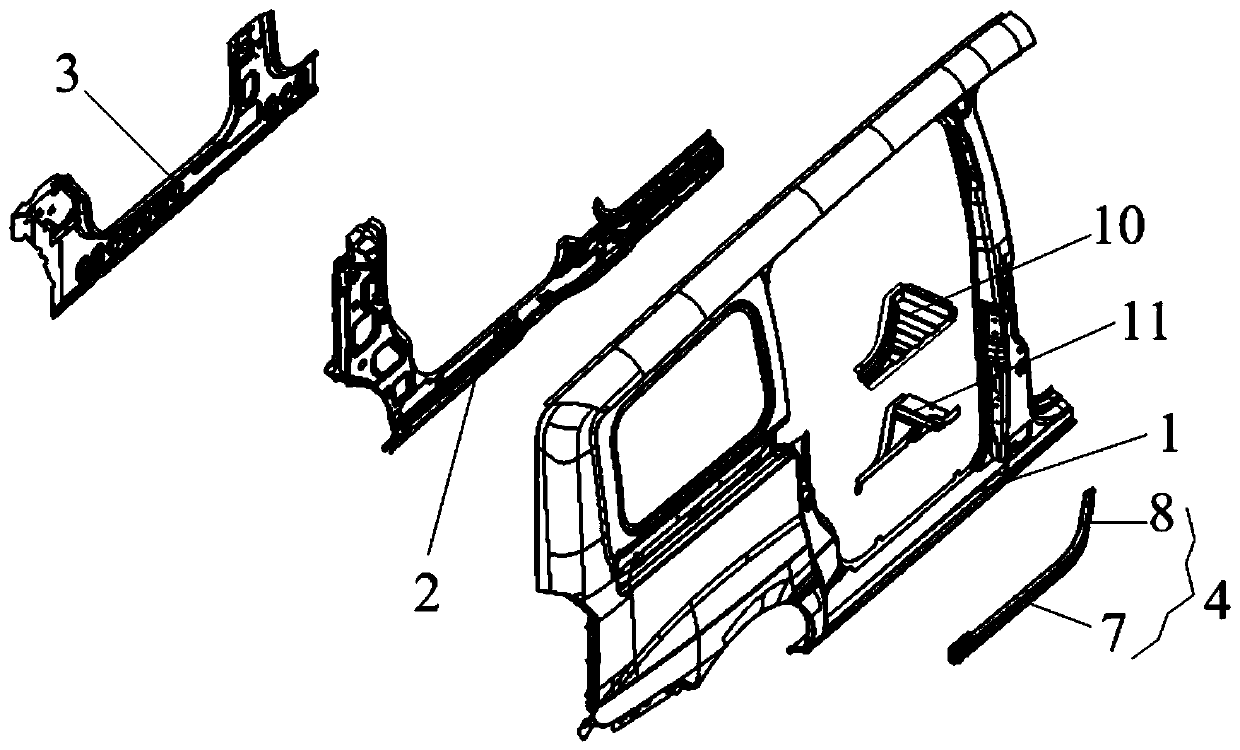

[0026] Embodiments of the invention: as image 3 , Figure 4 and Figure 5 As shown, a built-in sliding door lower guide rail installation structure includes a sill outer panel 1, a sill reinforcement panel 2, a sill inner panel 3 and a guide rail 4, wherein the sill outer panel 1 is a part of the car side wall outer panel, and the sill reinforcement panel 2 is located between the sill outer panel 1 and the sill inner panel 3, and the three are usually connected by welding. This embodiment also includes a rail box assembly. For installing the whole guide rail 4, the sill reinforcement plate 2 and the sill inner panel 3 are provided with a second through hole 6, the second through hole 6 is located at the end of the first through hole 5 close to the cab, and the guide rail box assembly runs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com