Method and composition for easy removal of nail coatings

A technology for nails, topcoats, applied in the direction of manicure, manicure or pedicure tools, applications, etc., can solve problems such as difficulty in removing the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

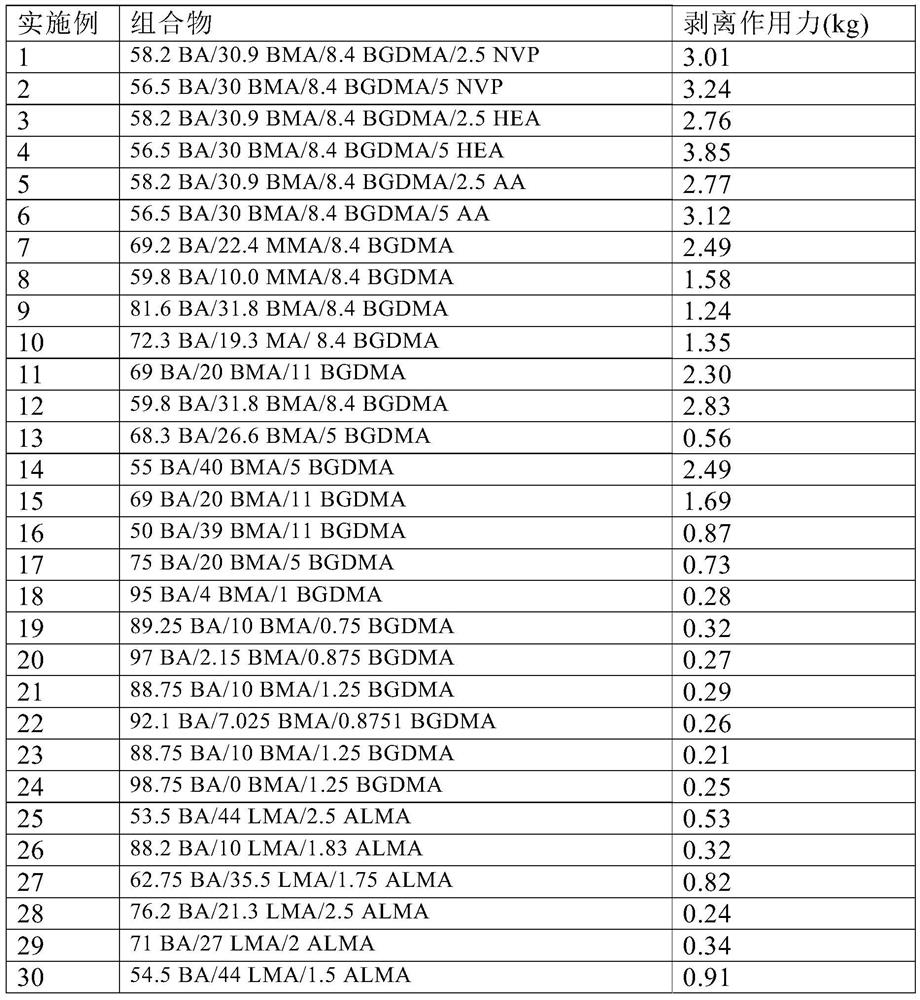

Examples

Embodiment

[0026] Synthesis of Adhesives

[0027] The following procedure describes the preparation of a representative crosslinked (meth)acrylate adhesive (butyl acrylate / butyl methacrylate / 1,3-butanediol dimethacrylate).

[0028] To a 500 mL resin flask equipped with a condenser, nitrogen inlet, mechanical stirrer with Teflon half-moon blades, and heating mantle was added 170.7 g of methyl ethyl ketone. The apparatus was placed under a gentle stream of nitrogen, water started to pass through the condenser, and stirring was started at 225 rpm. The solvent was then heated to 78 to 79°C and held. To the hot solvent were added 55.0 g of butyl acrylate, 40.0 g of butyl methacrylate, 5.0 g of 1,3-butanediol dimethacrylate, 1.0 g of VAZO 52 (2,2'-dimethacrylate) over 2 hours A solution of nitrogen bis(2,4-dimethylvaleronitrile) and 10.0 g of methyl ethyl ketone. The temperature of the reaction solution was allowed to rise to 80-82 °C during the addition. C for 30 minutes. Then a solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com