Spray control method and system based on volume feature pre-judging

A spray control and volume technology, which is applied in the device, application, animal husbandry and other directions of capturing or killing insects, can solve the problems of poor variable adjustment, deposition on the ground, waste of pesticides, etc., and achieves spray penetration. And the effect of high deposition, protection of ecological environment, and less waste of spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

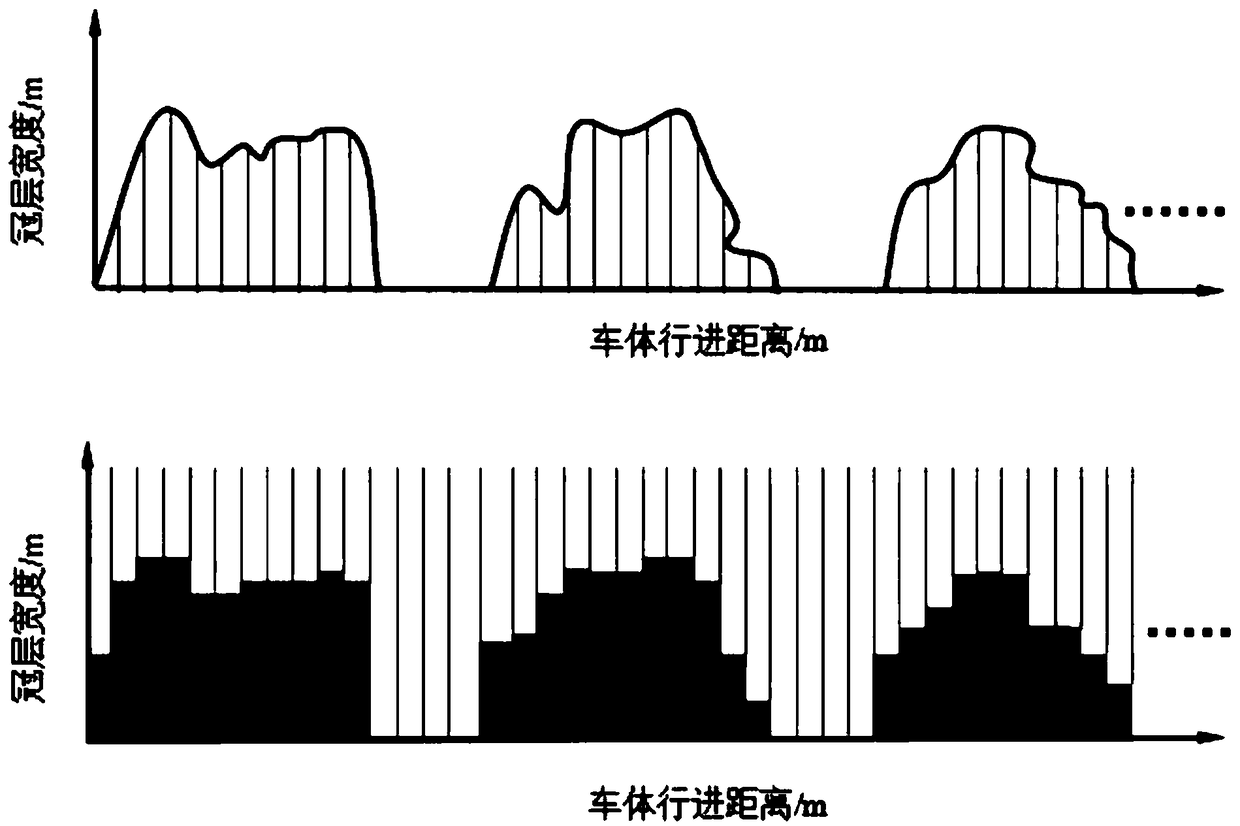

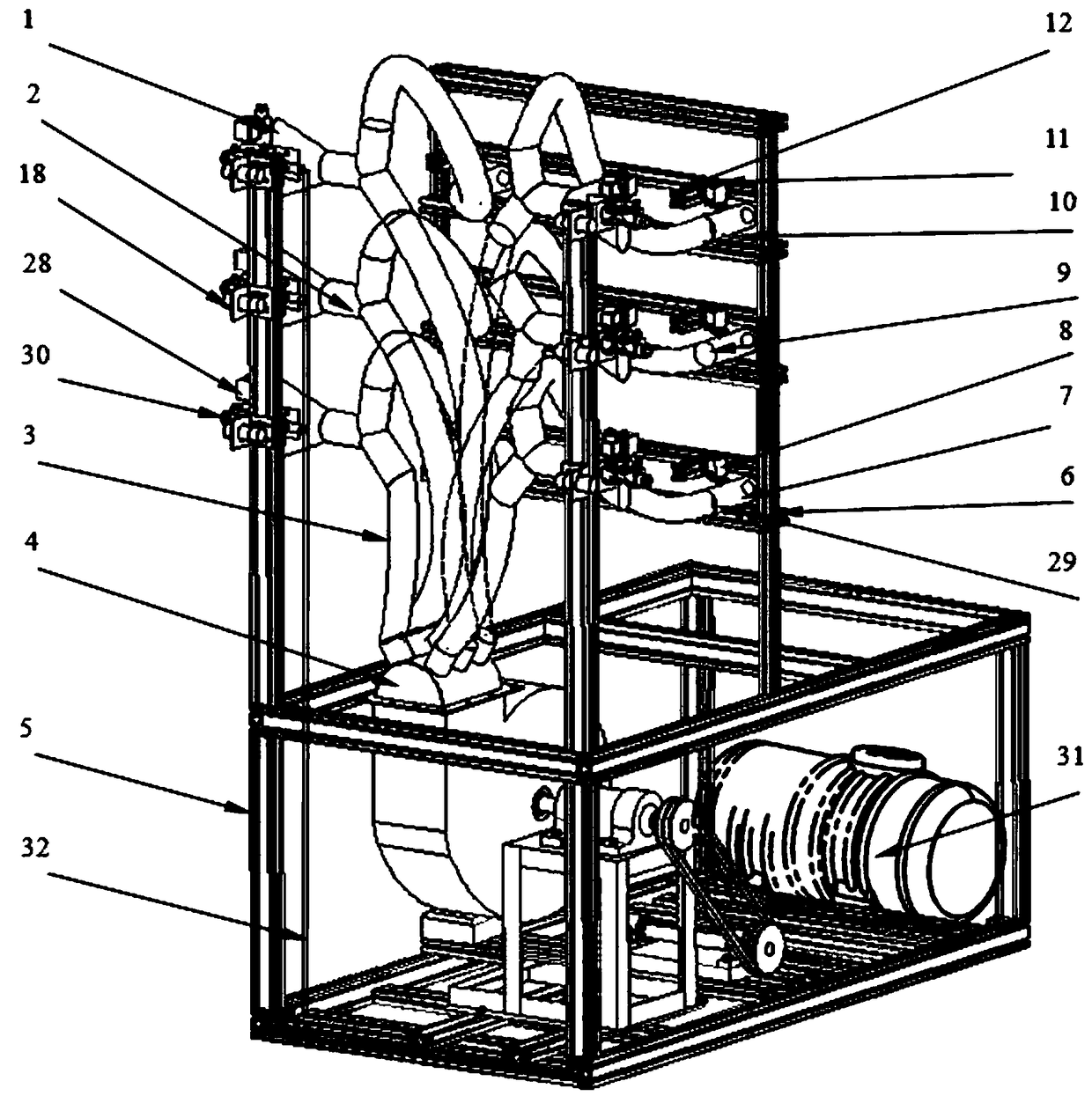

[0043] In the embodiment given herein, the spray control method based on volume characteristic prediction includes the following steps:

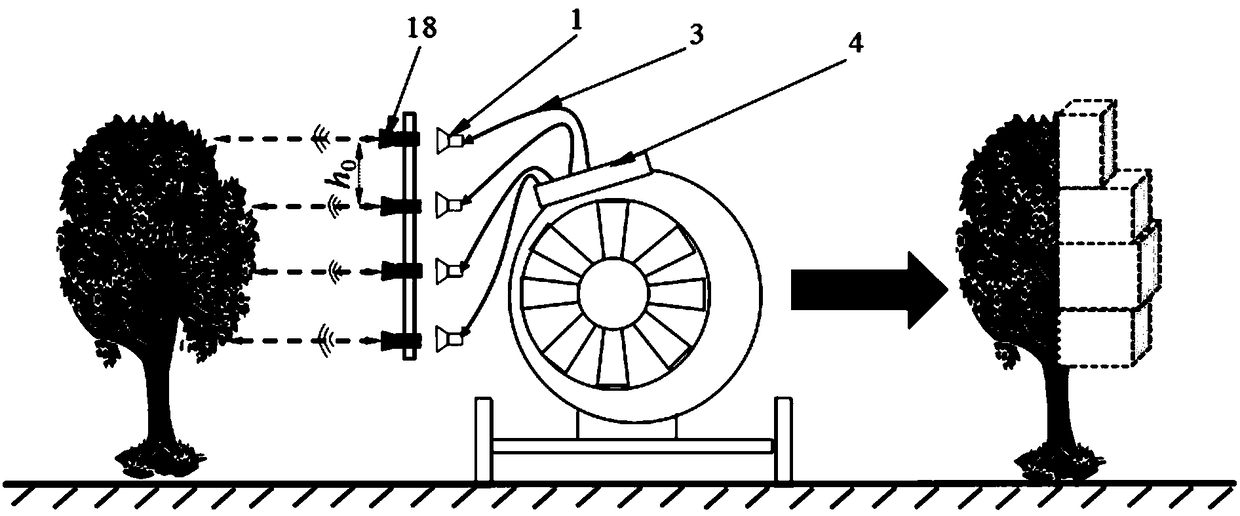

[0044] S1: Define the area sprayed by the sprayer for a certain distance L as the spray zone. When a spray zone starts, use several groups of detection points symmetrical to the center line of the sprayer body to detect the plants on one or both sides of the sprayer. (Take trees as an example below) for distance detection of the canopy. For example, in the case of spraying only the plants on one side of the sprayer, only one set of distance detection points can be set to detect the canopy distance of the plants on this side. If necessary To spray the plants on both sides of the sprayer, two sets of distance detection points can be set to detect the canopy distance of the plants on both sides.

[0045] Each group of distance detection points is located at a distance L in front of the spray outlet. The number of distance detection points in ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com