Partition board installing connecting piece

A technology of connectors and partition boards, which is applied in the direction of walls, building components, buildings, etc., can solve problems such as difficulties in installation and construction, difficulty in ensuring construction quality, etc., to ensure construction quality, avoid tight fit, and improve installation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

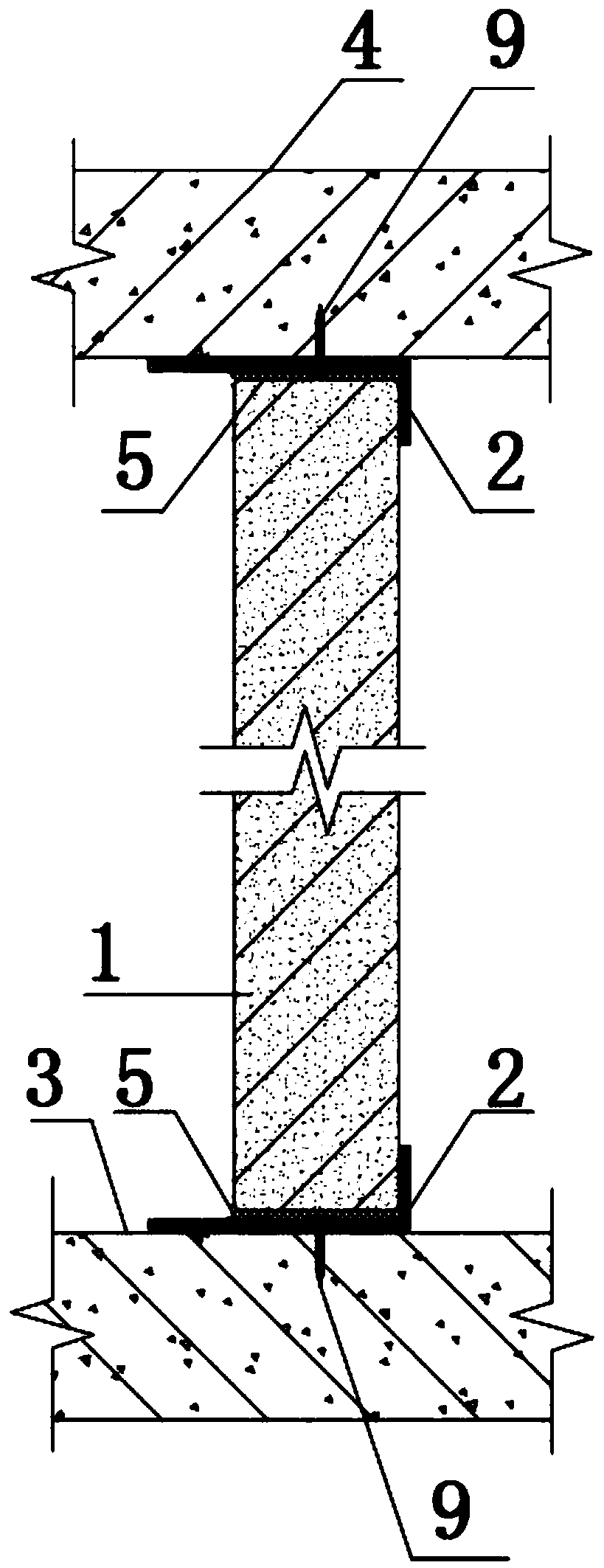

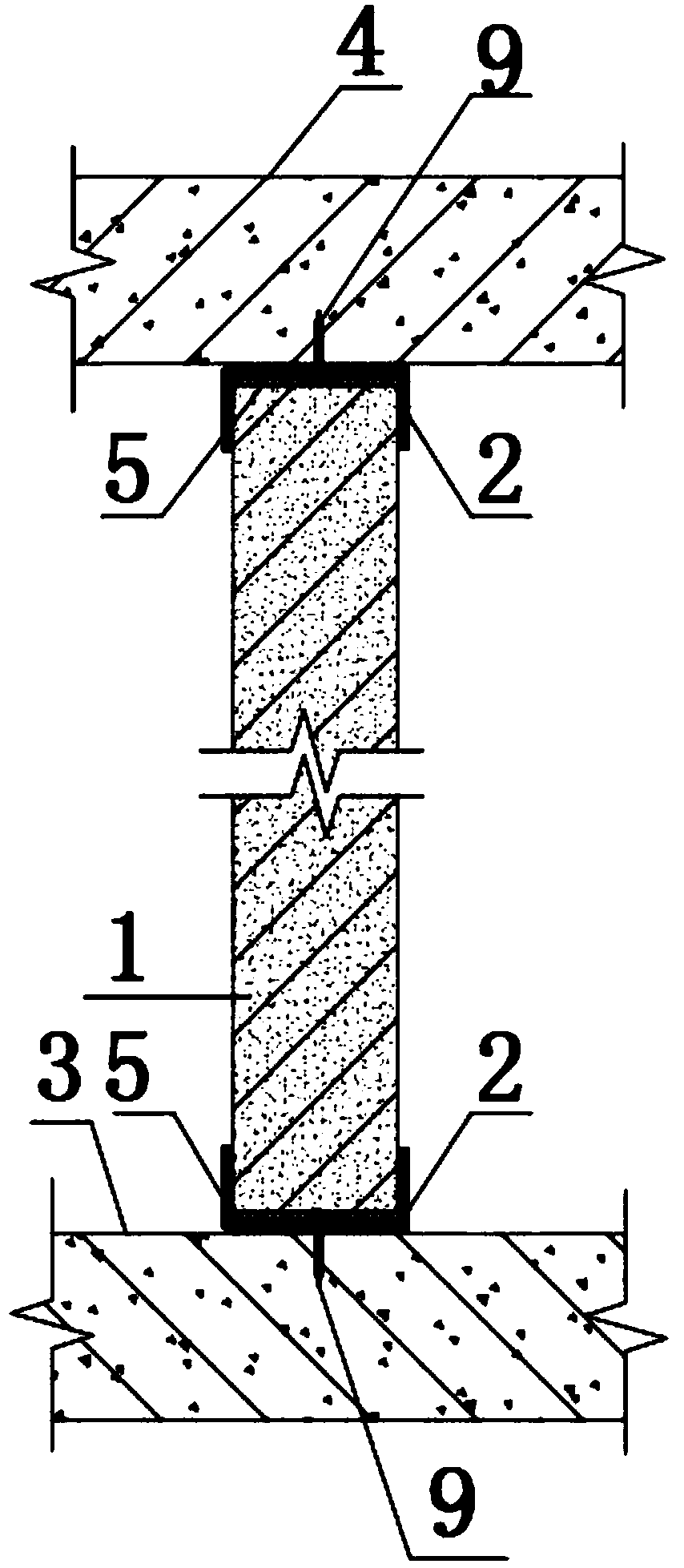

[0034] like Figure 1-6 As shown, a partition wall panel installation connector of the present invention includes a partition wall panel 1 and a wall panel connector 2, the wall panel connector 2 is a U-shaped steel structure with hinges, and the partition wall panel 1- One side is connected to the main structure A4 through the wall panel connector 2; the other side of the partition wall panel 1 is also connected to the main structure B3 through the wall panel connector 2;

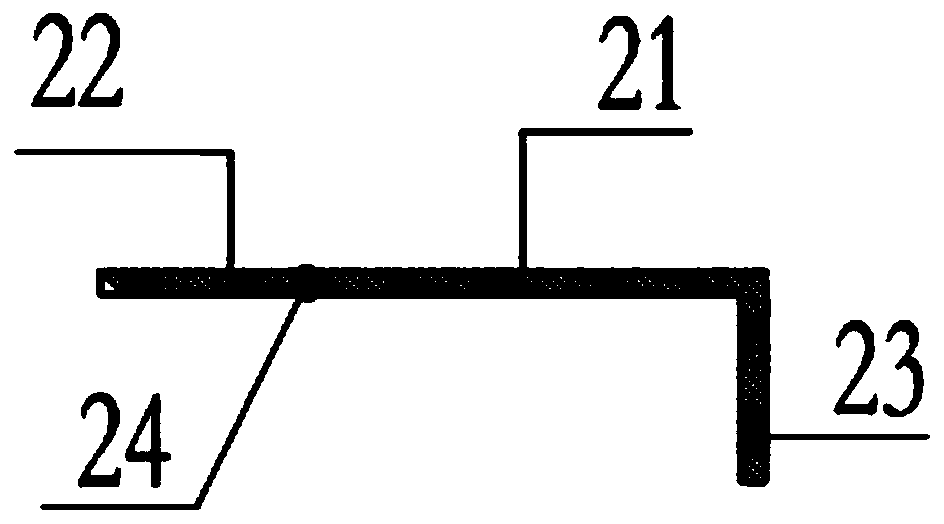

[0035] Described wallboard connector 2 comprises top board 21, left side flange board 22, right side flange board 23 and the hinge 24 that connects top board 21 and left side flange board 22; Top board 21 and right side flange board 23 are mutually In a vertical L-shaped structure, the left side flange plate 22 can rotate around a hinge 24 .

[0036] The space between the wall panel connector 2 and the partition wall panel 1 is filled with an upper elastic viscous material 5, such as silica gel, or other ...

Embodiment 2

[0040] like Figure 1-6 As shown, a method for installing a partition wall panel with a connector for installing a partition wall panel, install and fix one side of the partition wall panel 1 on the main structure A4 through the wall panel connector 2, and install and fix the other side of the partition wall panel 1 through the wall panel The connecting piece 2 is installed and fixed on the main structure B3, including the following steps:

[0041] A. Connect and fix the formed wall panel connector 2 with the main structure A4 using anchors 9, connect and fix the produced wall panel connector 2 with the main structure B3 using anchors 9, and the two wall panel connectors 2 correspond set up;

[0042] B, construction of elastic viscous material 5 on top plate 21 of wallboard connector 2;

[0043] C. Fully unfold the left side flange plate 22 on the wall panel connector 2, move the partition wall panel 1 between the main structure A4 and the main structure B3, and clamp the tw...

Embodiment 3

[0048] like Figure 1-8 As shown, a method for installing a partition wall panel with a connector for installing a partition wall panel, to realize this embodiment, only needs to further improve the structure of the wall panel connector 2 on the basis of Embodiment 1, mainly to make the top plate 21 The installation position with the main structure is moved to the left extension installation plate 7 and the right extension installation plate 8, the top plate 21 of the wall panel connector 2 is provided with the left extension installation plate 7 corresponding to the left flange plate 22 up and down, The left extension mounting plate 7 is integrated with the top plate 21 , and when the left flange plate 22 is unfolded, the left extension mounting plate 7 and the left flange plate 22 are on the same plane structure.

[0049] Further, the top plate 21 of the wall panel connector 2 is provided with a right side extension mounting plate 8 corresponding to the right side flange pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com