Method for improving bridge strain monitoring sensitivity

A strain monitoring and sensitivity technology, which is applied in the direction of force measurement, measurement force, and measurement device by measuring the change of optical properties of materials when they are stressed, which can solve the problems of insufficient measurement sensitivity and affect measurement accuracy, and improve monitoring sensitivity. , Good strain sensitivity, uniform deformation under force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] This embodiment provides a method for improving the sensitivity of bridge strain monitoring;

[0037] like figure 1 As shown, the method for improving bridge strain monitoring sensitivity in the present embodiment comprises the following steps:

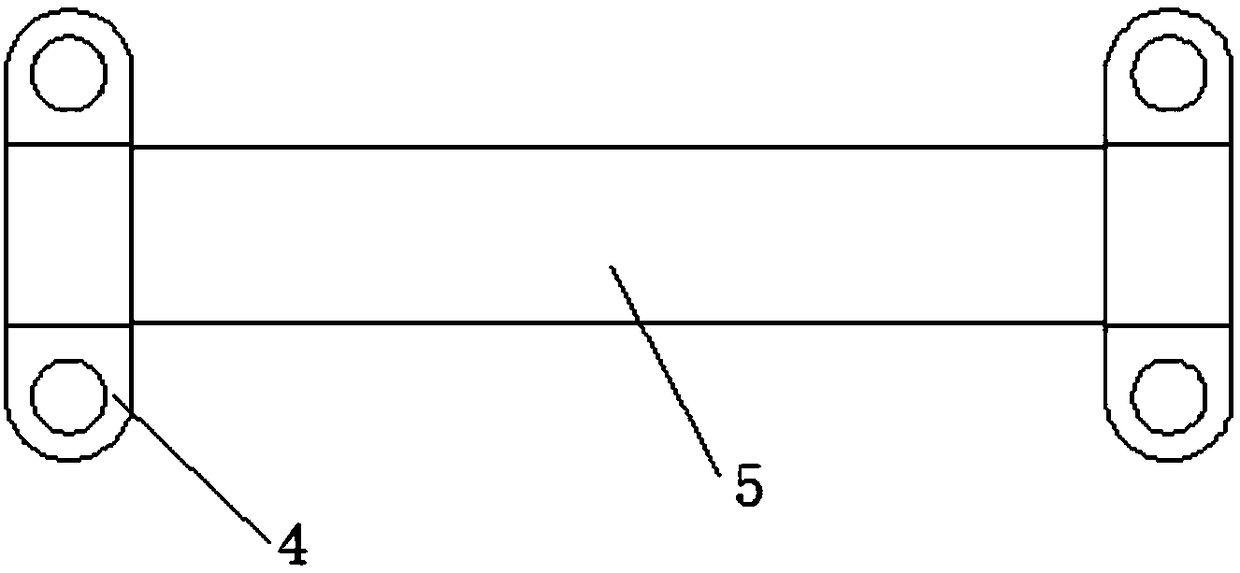

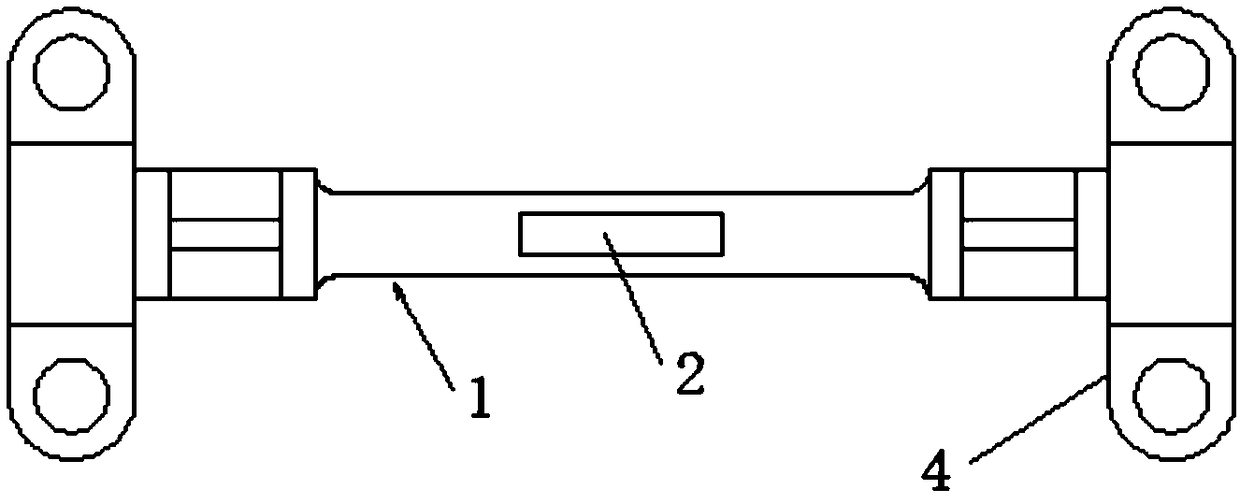

[0038] Step 1, setting the force-bearing member 1 along its longitudinal direction as a plurality of measuring sections with different cross-sectional areas;

[0039] Step 2, setting the sensitive element 2 on the measurement section with a smaller cross-sectional area on the force-bearing member 1;

[0040] Step 3: Fix both ends of the stressed member along the stressed direction of the bridge.

[0041]In this method, the stressed member is arranged as a plurality of measuring sections with different cross-sectional areas along its longitudinal direction. The strain of the measuring section of the cross-sectional area is different. The strain sensitivity of the large cross-sectional area is poor, and the strain sensitivity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com