Spring bolt damp buffering mechanism

A cushioning mechanism and damping technology, which is applied in the direction of building locks, building structures, non-mechanical drive locks, etc., can solve the problems of collision and noise between the lock tongue and the buckle box, and achieve the effect of reducing collision noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

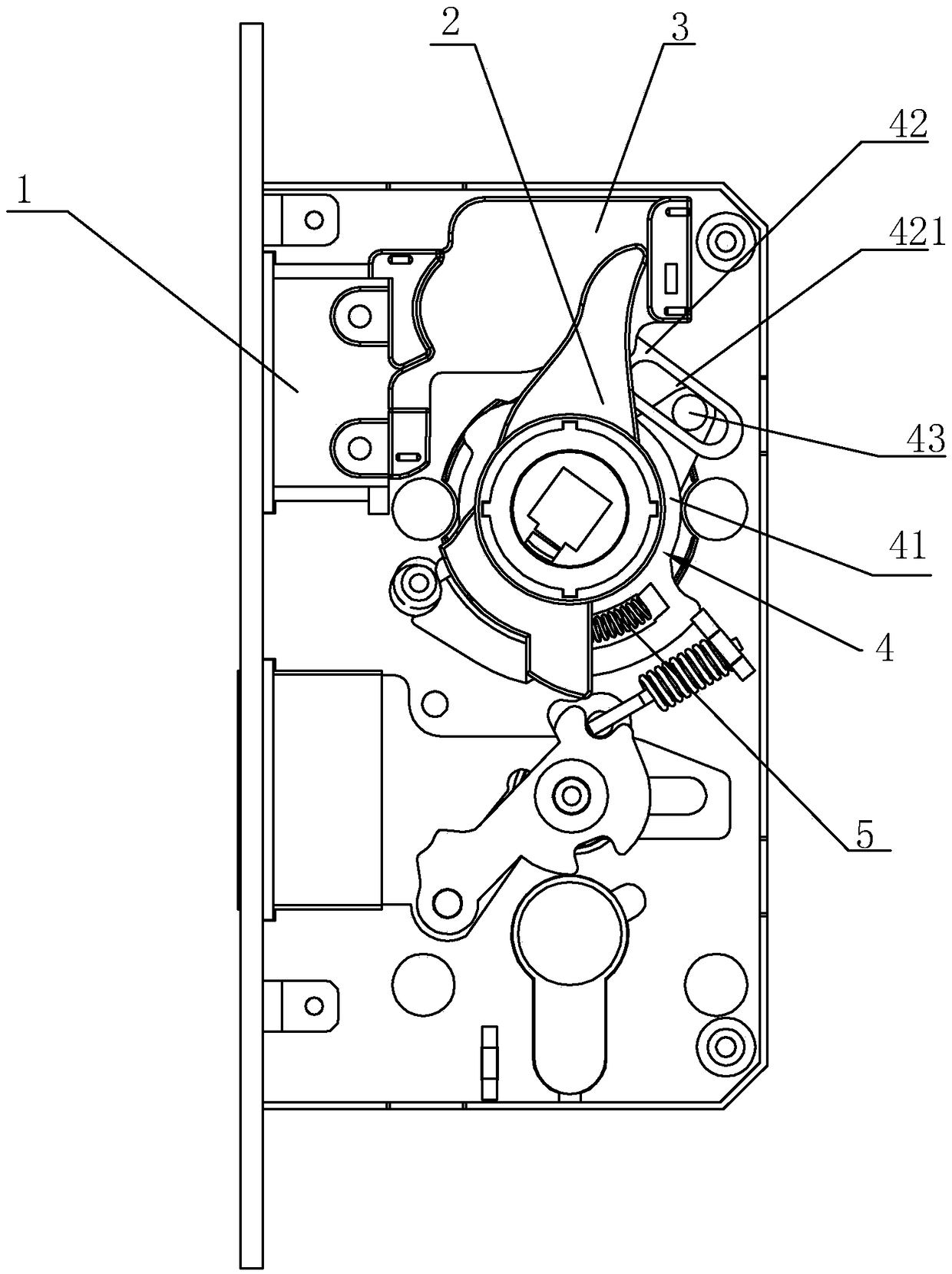

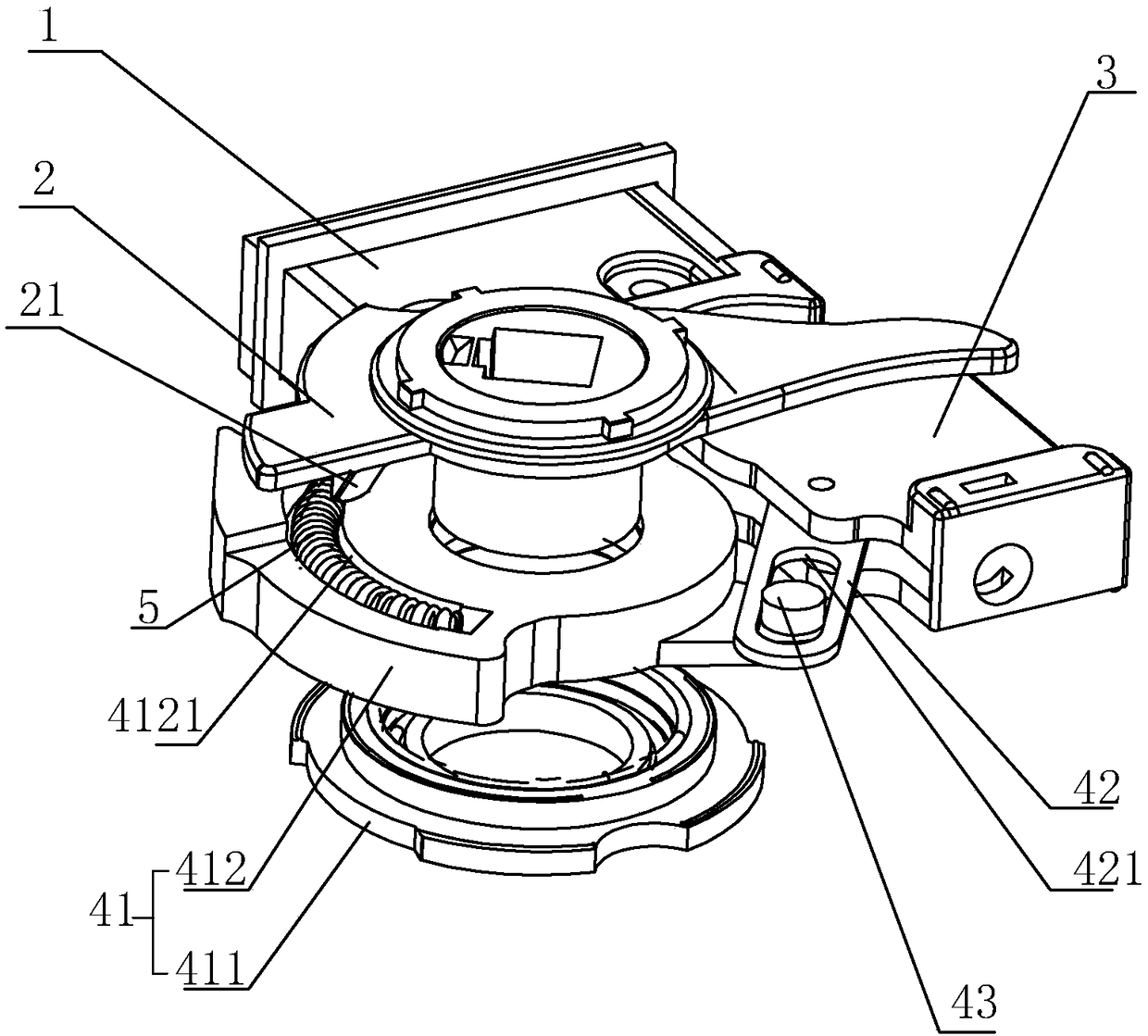

[0019] Refer to attached Figure 1 to Figure 2 An embodiment of a deadbolt damping buffer mechanism of the present invention will be further described in detail.

[0020] A deadbolt damping buffer mechanism, comprising a deadbolt 1 and a deadbolt driving part 2 for driving the deadbolt 1 to move, the other end of the deadbolt 1 is provided with a sliding plate 3, and the handle can drive the deadbolt driving part 2 rotates, thereby driving the sliding plate 3 of the slide plate, and driving the dead bolt 1 to move;

[0021] One side of the slide plate 3 is provided with a buffer device 4 for slowing down the ejection speed of the deadbolt 1; the buffer device 4 includes a damper 41 and a linkage piece 42 hinged with the slide plate 3, and the linkage piece 42 is close to the buffer One end of the device 4 is provided with a chute 421, and the damper 41 is provided with a linkage part 43 matched with the chute 421. The linkage part 43 is placed in the chute 421. When it pops ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com