Anti-tilting dual protection device of hanging basket

A double-protection, basket-proof technology, applied in the direction of hoisting equipment safety devices, hoisting devices, etc., can solve the problems of increased maintenance difficulty, poor interchangeability, and low precision of safety locks and ropes, so as to reduce wear fatigue and impact Stress, anti-tilt reliability improvement, and the effect of improving the reliability level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

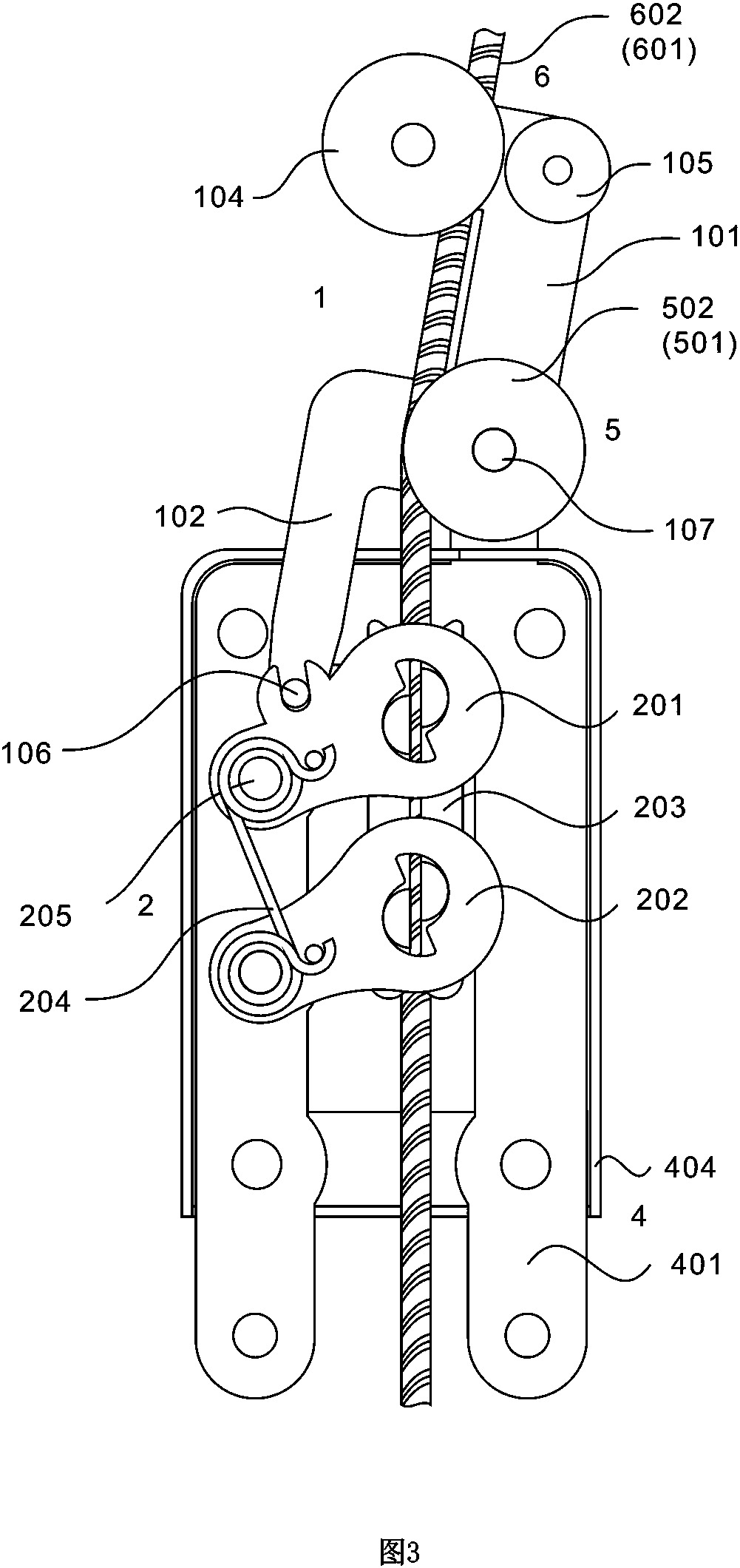

[0068] The working principle of the present invention is as figure 1 As shown, the two hanging basket anti-tilt double protection devices are installed respectively upstream of the two lifting points N formed by the hoist 701 on the suspension platform 7, which include the swing arm mechanism 1, the rope clamping mechanism 2 or 3 and the housing 4. The rope clamping mechanism 2 or 3 is two groups, in which the safety rope 601 and the working rope 602 pass through respectively; the swing arm mechanism 1 is connected to the two groups of rope clamping mechanisms 2 or 3 at the same time; the swing arm mechanism 1 and the working rope 602 offset; because the load of the working rope 602 is always perpendicular to the ground, and the housing 4 is just connected to the suspension platform 7, the swing ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com