Antiskid support frame for repairing industrial equipment

A technology for industrial equipment and support frames, which is applied to lifting frames, lifting devices, etc., can solve the problems of inconvenient movement, inconvenient storage and access of maintenance tools and parts, achieve convenient disassembly, solve inconvenient fine-tuning movement, and reduce maintenance difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

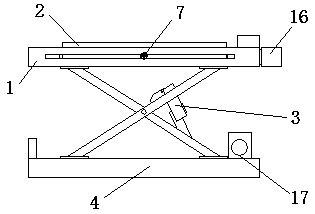

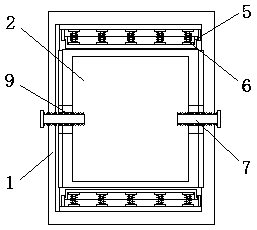

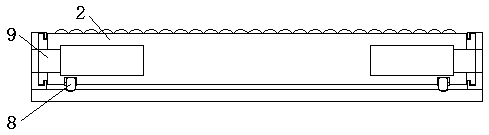

[0020] See Figure 1-Figure 4 , The present invention provides an industrial equipment maintenance anti-skid support frame, including a maintenance support frame main body 17, a load-bearing support base 4 is fixedly arranged at the bottom of the maintenance support frame main body 17, and a jack 3 is fixedly arranged on one side of the load-bearing support base 4. The top of the frame body 17 is fixedly provided with a protective load-bearing plate 1, the front surface of the protective load-bearing plate 1 is fixedly provided with a first magnetic plate 10 by bolts, both sides of the protective load-bearing plate 1 are provided with fixed threaded posts 7, and the protective load-bearing plate 1 The inner side of the protective bearing plate 2 is fixedly provided with a sliding f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com