Cable test vehicle

A cable test and compartment technology, applied in the field of vehicles, can solve problems such as incomplete functions and single functions, and achieve the effect of small space occupation, good user experience, and rich compartment configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

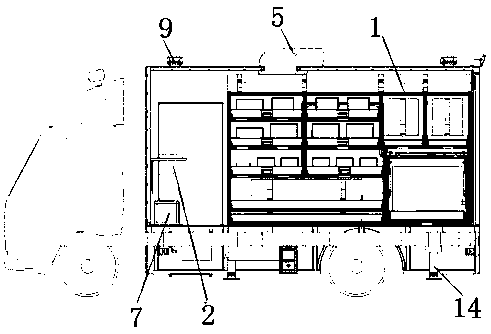

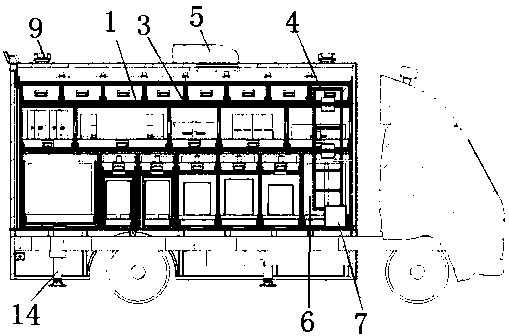

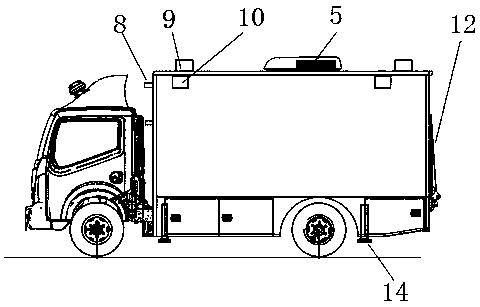

[0024] Such as Figure 1 to Figure 5 As shown, a cable test vehicle is provided with tool racks 1 on the left and right sides of the vehicle compartment, tool management system 2 and power distribution box; the tool rack 1 is provided with several layers, and each layer is equipped with several There are three compartments, which are semi-closed to facilitate observation of the instrument. Each compartment is equipped with a pull-out slide rail 3 for easy removal of the equipment. There is also a 220V power socket in the compartment for the convenience of tools. For daily charging, the tool rack 1 is also provided with a climbing ladder 4 that can slide left and right, which is convenient for picking and placing tools. The tool management system 2 can query and manage various information of tools in the car. Electrical equipment control.

[0025] The tool rack 1 is used to place various instruments and related tools and utensils, which are reasonably stored according to funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com