A two-way opening and closing hydraulic buffer hinge

A hydraulic buffer and hinge technology, which is applied to hinge plates, switches with braking devices, buildings, etc., can solve the problems of reduced service life of hinges, hydraulic oil turbulent flow disturbance, and loud noise, so as to improve the use of The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

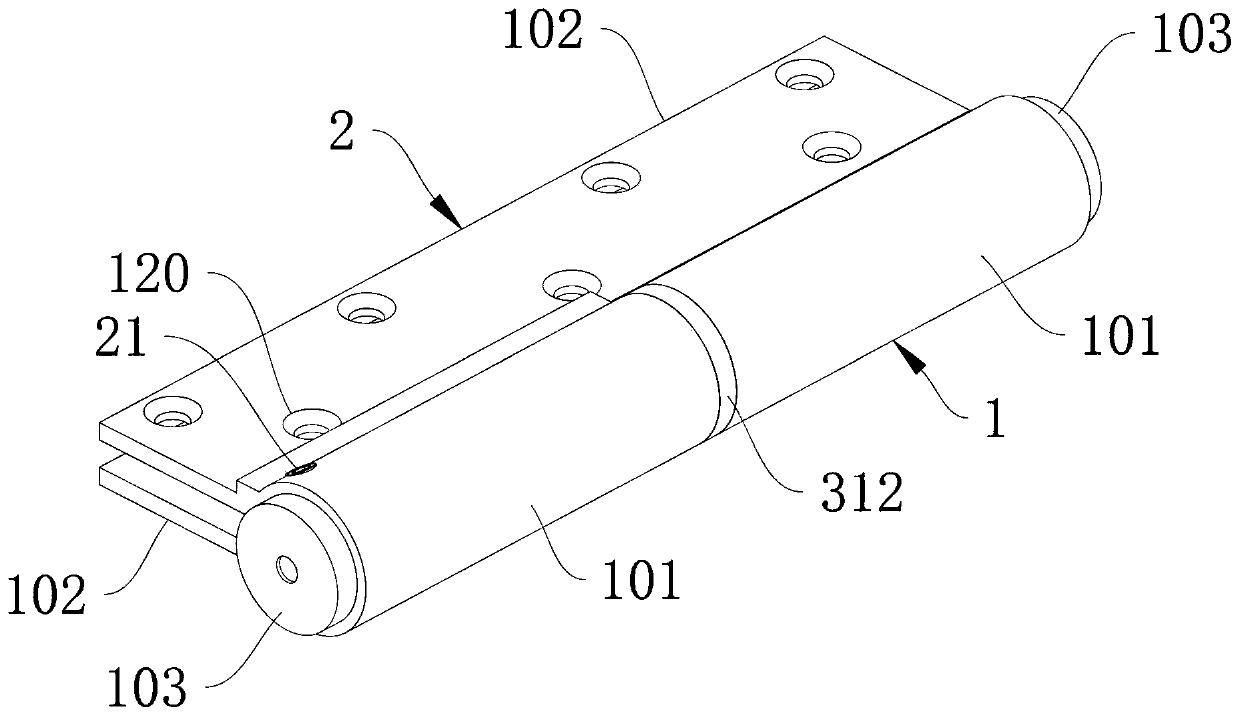

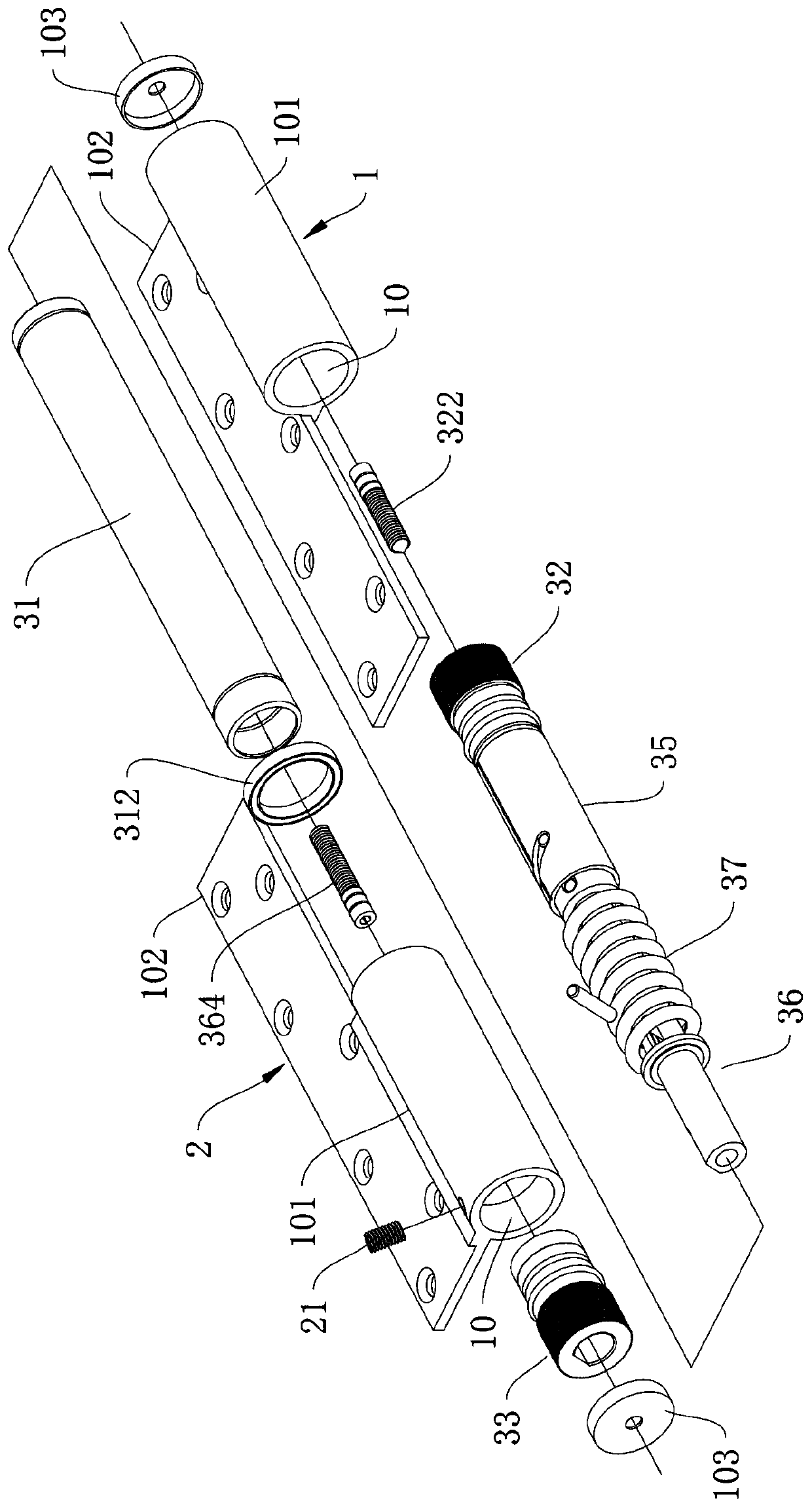

[0016] Such as figure 1 , figure 2 and Figure 4 As shown, a two-way opening and closing hydraulic buffer hinge according to the present invention includes a first hinge body 1, a second hinge body 2, and a mandrel device 3, and the first hinge body 1 and the second hinge body The page body 2 is assembled and connected together by the mandrel device 3, which is characterized in that: the mandrel device 3 includes a mandrel tube body 31, a first sealing connector 32, a second sealing connector 33, a movable piston cam 34, a position limiting Cylinder sleeve 35, rotating connecting shaft 36, spring 37, limit pin 38, one-way valve 343.

[0017] Among them, such as Figure 5 As shown, the outer end of the first sealing connector 32 is provided with a threaded adjustment hole 321, the threaded adjustment hole 321 is provided with an adjustment screw plug 322, and the two sides of the hole wall of the threaded adjustment hole 321 are respectively provided with The oil return ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com