Synthetic leather wet production line ironing wheel transmission equipment

A technology of transmission equipment and synthetic leather, applied in textiles and papermaking, etc., can solve the problems of inseparability, the transmission device is not equipped with automatic heat dissipation function, and the working status of the components in the device cannot be known in real time, so as to achieve the effect of convenient inspection and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

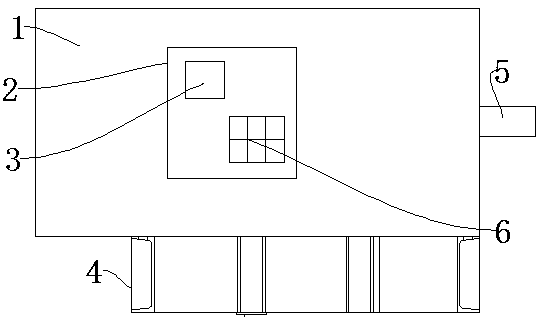

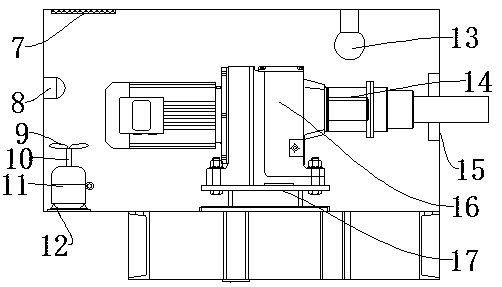

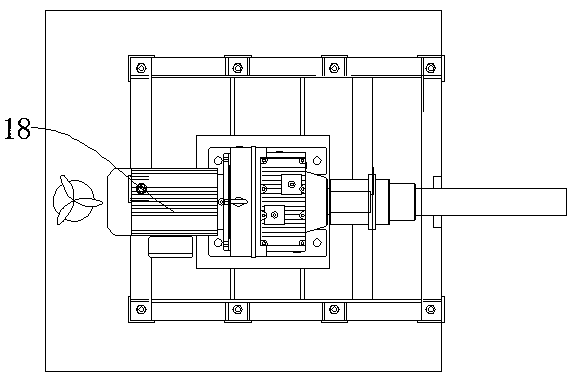

[0019] Such as Figure 1-Figure 3 As shown, a synthetic leather wet normal ironing wheel transmission device includes a base 4, a protective cover 1 and a cooling net 7, the top surface of the base 4 is provided with a protective cover 1, and the inner bottom surface of the protective cover 1 is provided with a mounting seat 17 , the mounting base 17 is provided with a reducer 16, the side of the reducer 16 is provided with a drive motor 18, the other side of the reducer 16 is provided with a coupling 14, the end of the coupling 14 is provided with a drive shaft 5, and the outside of the drive shaft 5 A sealing ring 15 is provided, a motor frame 12 is provided on the side of the mounting base 17, a servo motor 11 is provided on the motor frame 12, a rotating shaft 10 is provided at the end of the servo motor 11, and a fan blade 9 is provided at the end of the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com