Garbage bag sealing mechanism and intelligent garbage can

A technology of garbage cans and garbage bags, which is applied in the directions of garbage cans, garbage collection, transportation and packaging, etc., can solve the problems of poor packing sealing, garbage bags without automatic packing mechanism, and weak sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] This specific embodiment provides an intelligent garbage can and a garbage bag packing mechanism, which solves the problem that the existing intelligent garbage can has no automatic packing mechanism or can only pack garbage bags semi-automatically and the sealing of the garbage bag is not strong and the seal is not firm. The problem of weak carrying capacity.

[0029] Hereinafter, embodiments will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

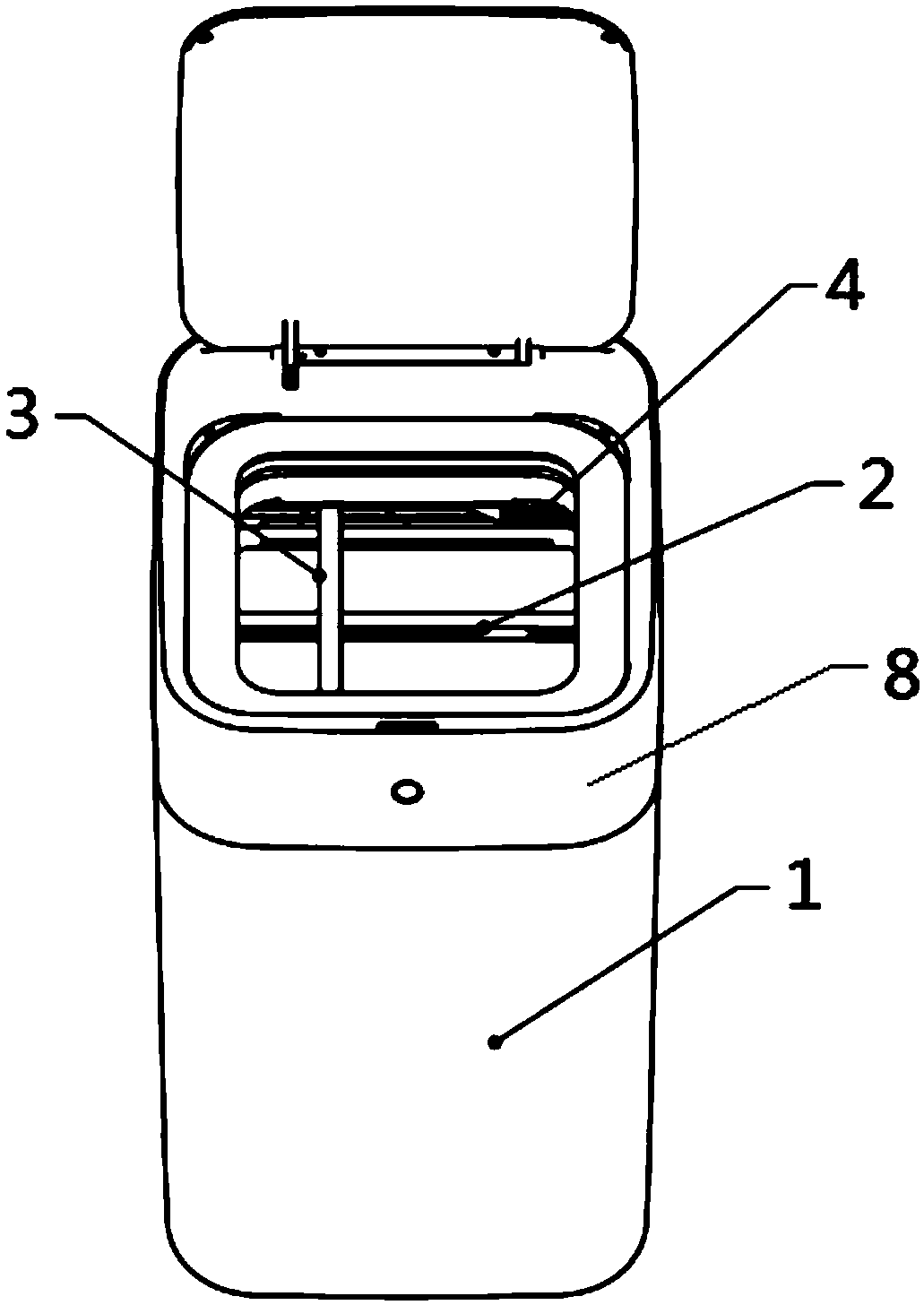

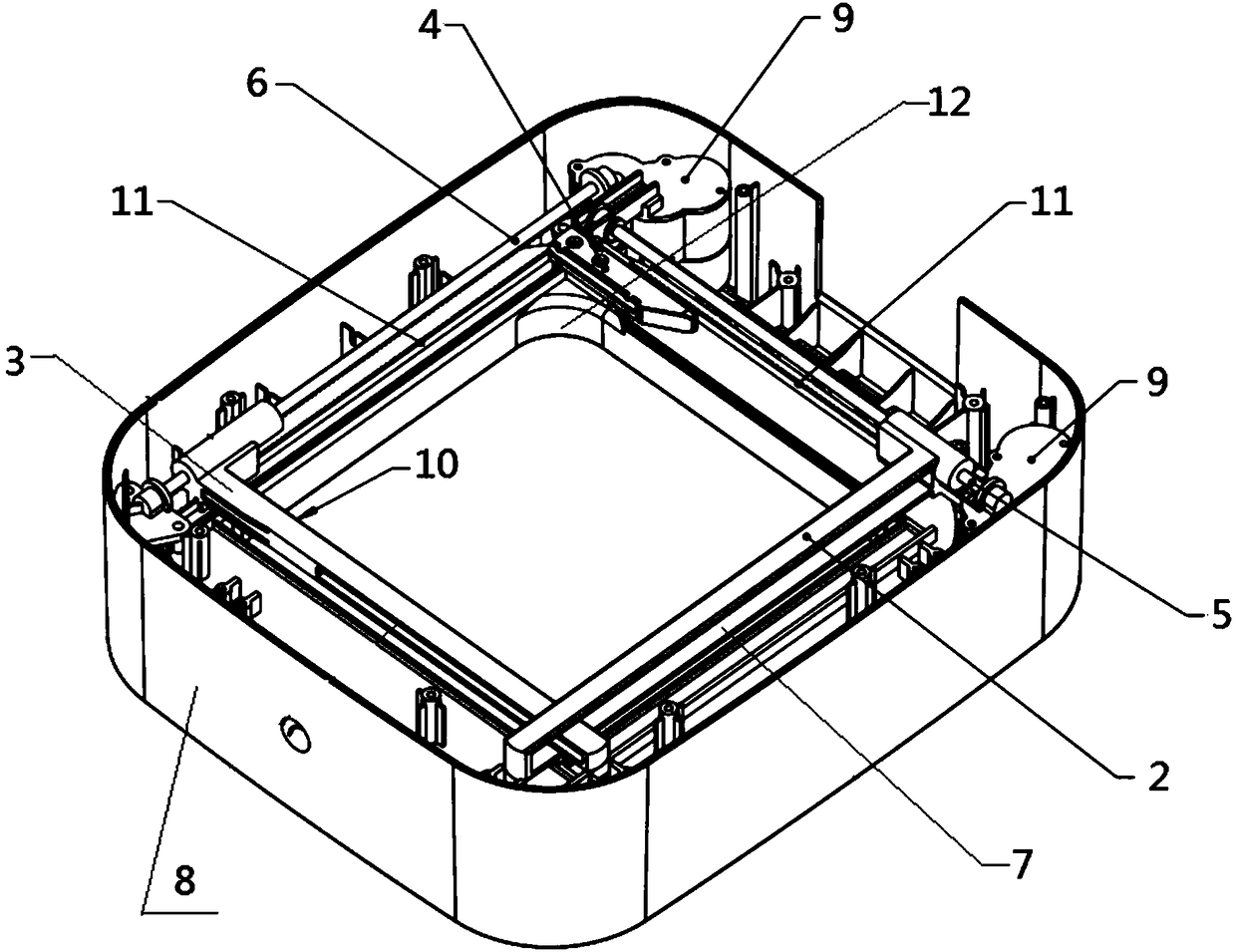

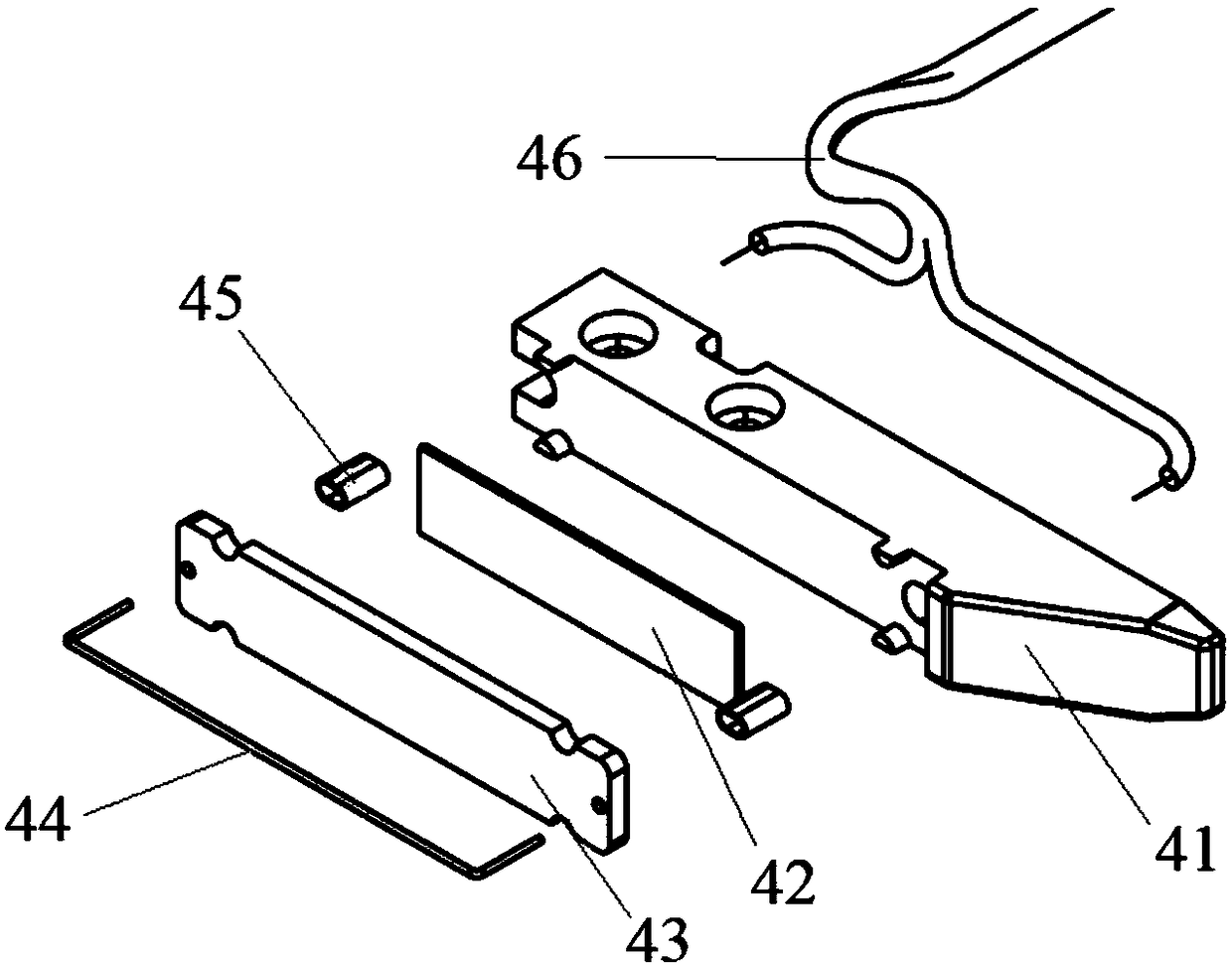

[0030] Please refer to the attached Figure 1-2 , a garbage bag packaging mechanism for an intelligent garbage can provided in this embodiment is used to automatically close and seal the opening of a garbage bag full of garbage, and is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com