Painting device for plastic model part

A technology for plastic models and parts, applied in the field of painting devices for plastic model parts, can solve the problems of poor painting effect of plastic model parts and indoor air pollution, and achieve the effect of avoiding flow and improving the effect of painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

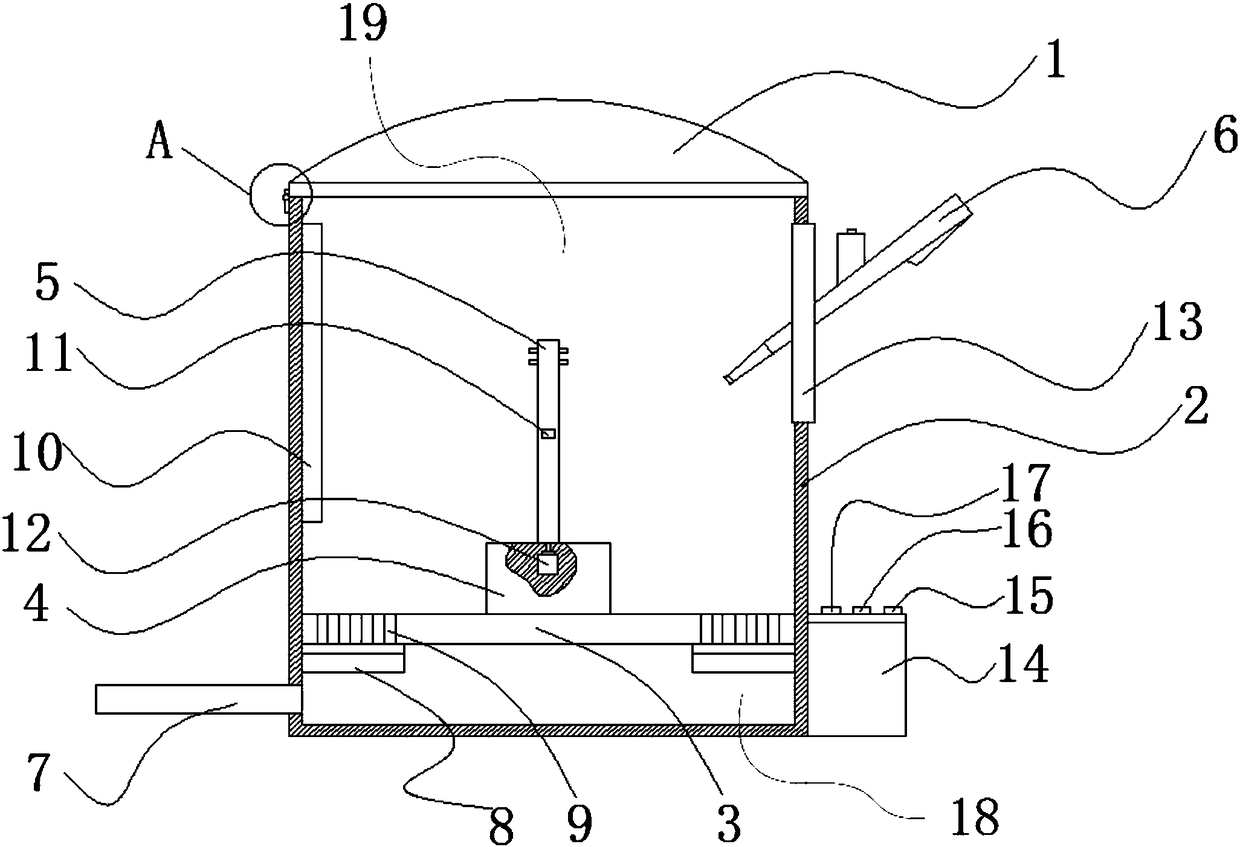

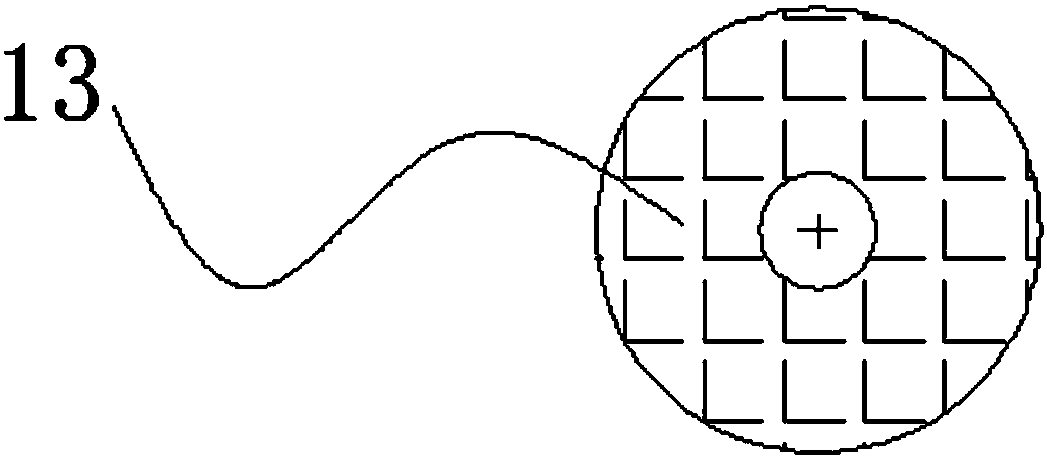

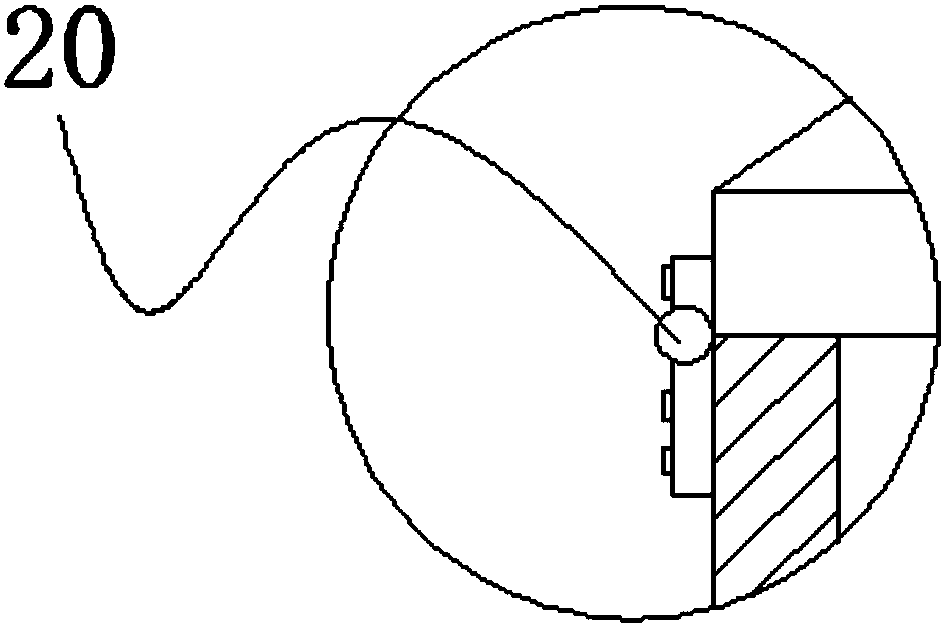

[0027] Embodiment 1: as figure 1 , figure 2 and image 3 As shown, it includes: top cover 1, shell 2, support plate 3, base 4, fixed rod 5, airbrush 6, exhaust pipe 7, exhaust device 8, ventilation grill 9, heating part 10, temperature sensor 11 , driving device 12, movable connection part 13, controller 14, forward rotation button 15, reverse button 16, exhaust button 17, exhaust part 18, painting part 19 and hinged device 20;

[0028] The top cover 1 is movably arranged on the top of the housing 2; the joint between the top cover 1 and the housing 2 is provided with a hinged device 20; the top cover 1 is set as a protruding light-transmitting glass; so that the user can paint the parts , prevent the harmful gas emitted by the paint from being distributed into the room, and also prevent the dust in the air from falling on the painted surface that has been sprayed, so as to improve the painting effect.

[0029] The inner wall of the housing 2 is provided with a heating par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com