A Dynamic Tensile Failure Evaluation Method for Fiber Reinforced Composite Materials

A technology of dynamic stretching and fiber reinforcement, applied in instrumentation, design optimization/simulation, calculation, etc., can solve problems such as lack of theoretical basis and failure to consider strain rate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

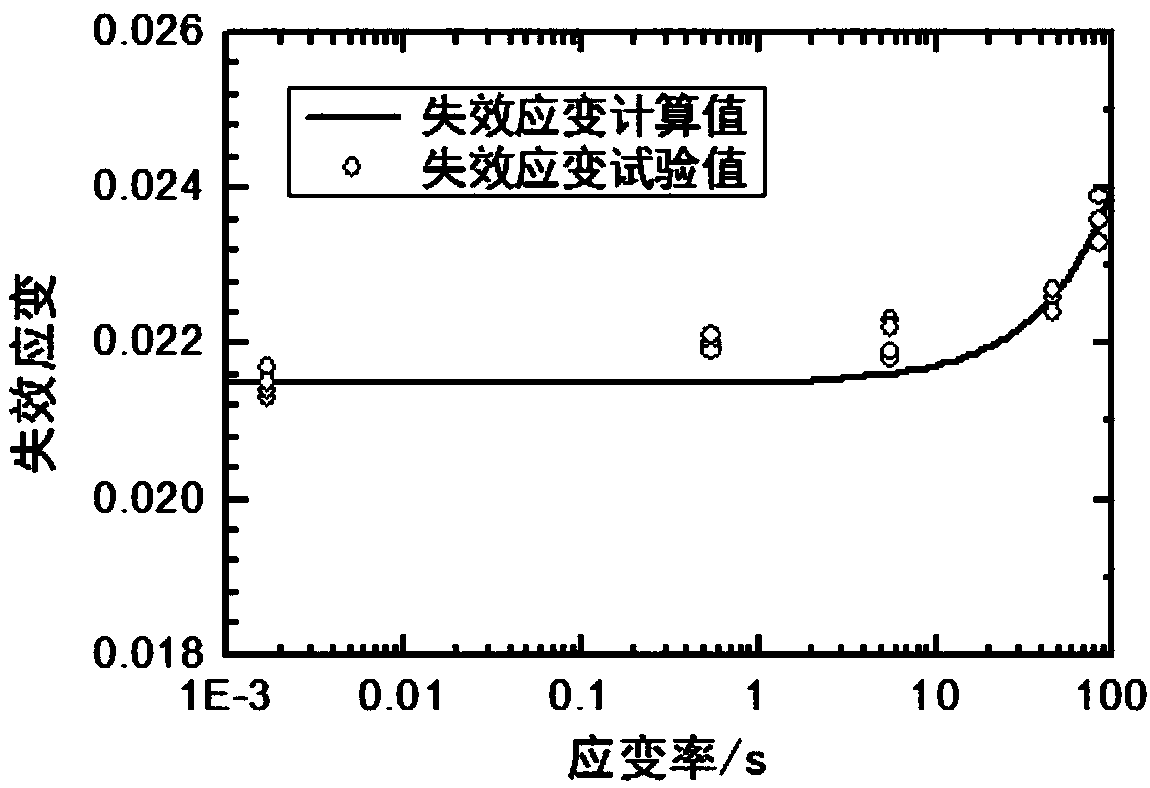

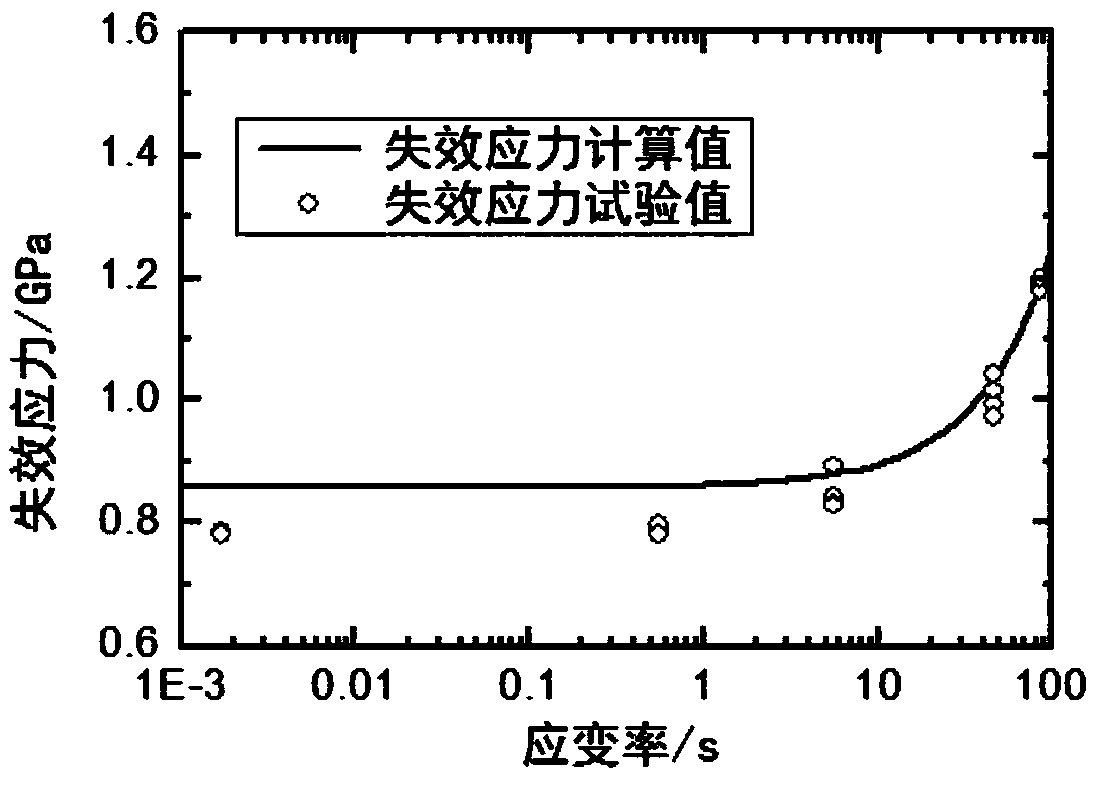

[0070] A method for evaluating dynamic tensile failure of fiber reinforced composite materials. Fiber reinforced composite laminates are selected as the analysis object, and the length, width and height of the specimen are 12.7mm×12.7mm×1mm. The material of the specimen is a fiber reinforced composite material with a fiber volume fraction of 50%, and its material parameters are shown in Table 1, where E 1 ,E 2 ,E 3 are the elastic modulus in the three main directions of the material, v 23 , v 13 , v 12 are the corresponding Poisson's ratios, respectively. Failure strain ε at different strain rates 1s and the failure stress σ 1s As shown in table 2.

[0071] Table 1 Parameters of fiber reinforced composites

[0072]

[0073] Table 2 Failure strain and failure stress of fiber reinforced compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com