Waste discharging and material collecting device and waste discharging method for OCA material

A material receiving device and waste material rewinding technology, applied in chemical instruments and methods, winding strips, electronic equipment, etc., can solve problems such as low efficiency, affecting product quality, and poor stability of manual operation, so as to improve product quality, Improve production efficiency and product quality, and realize the effect of fully automatic waste discharge operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

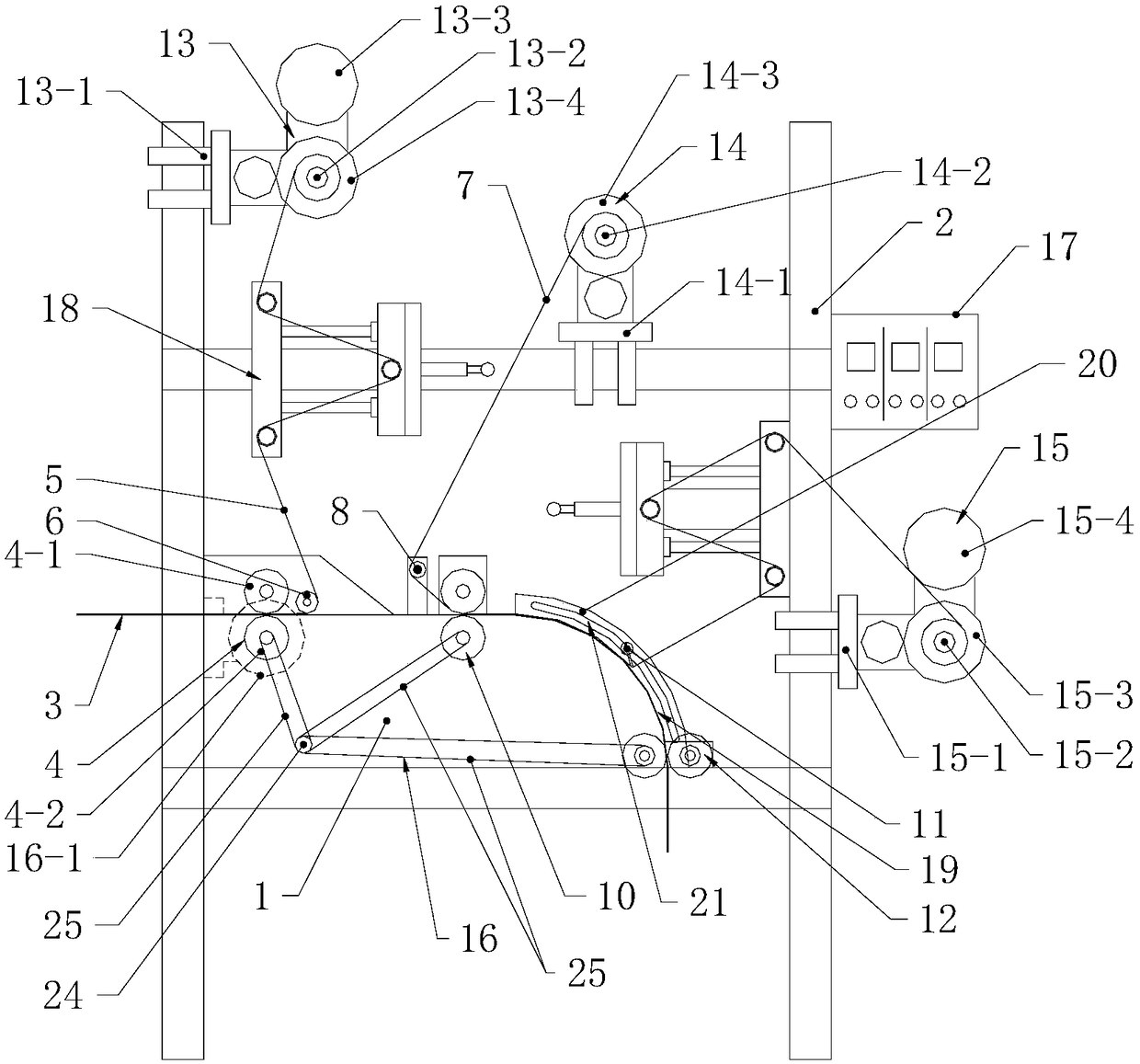

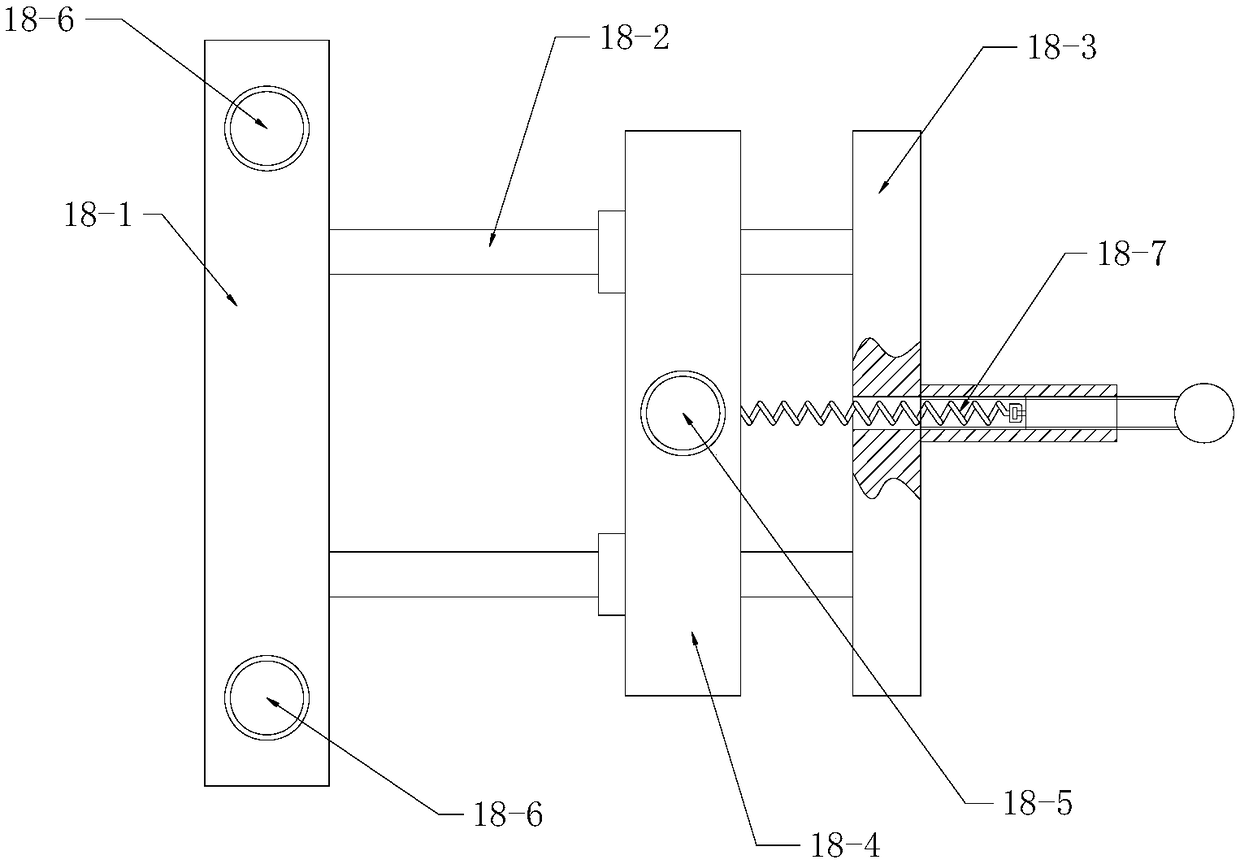

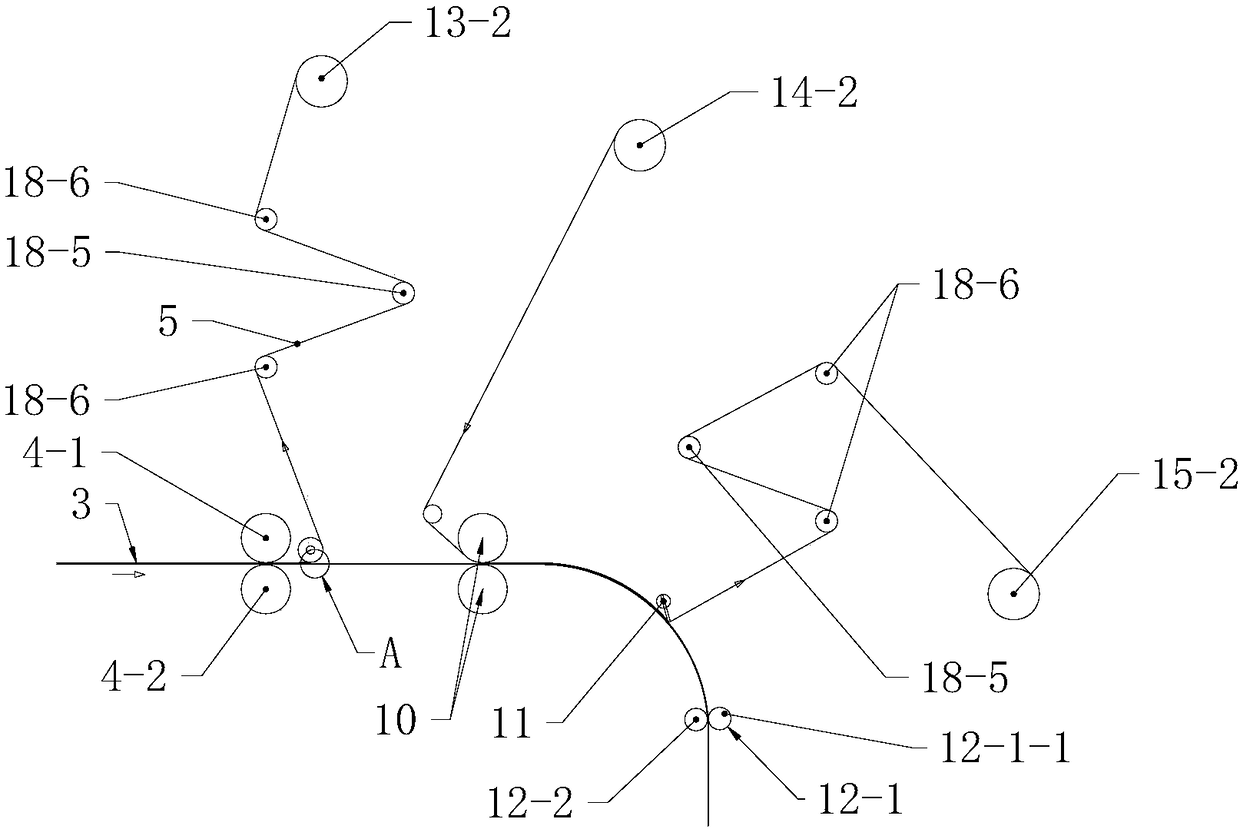

[0040] Such as Figure 1 ~ Figure 6 The shown waste discharging and collecting device for OCA materials includes an OCA material conveying platform 1 and a waste discharging bracket 2 located on one side of the conveying platform 1. The conveying platform 1 is sequentially arranged along the direction of the OCA material 3 to drive the OCA material 3 forward. The main rubber roller set 4, the waste discharging roller 6 used to change the forward direction of the cover film waste 5, the small passing roller 8 used to guide the transfer film 7, the cover film roller set used for the composite transfer film 7 and the OCA adhesive layer 9 10. The waste discharge knife 11 used to adjust the peeling angle of the transfer film 7 and the auxiliary rubber roller set 12 used to pull the OCA material 3 forward. The waste discharge support 2 is also connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com