Laying tool

A technology for tooling and positioning elements, which is applied in the field of laying tooling for laying main beam glass fiber cloth, and can solve the problems of low laying efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

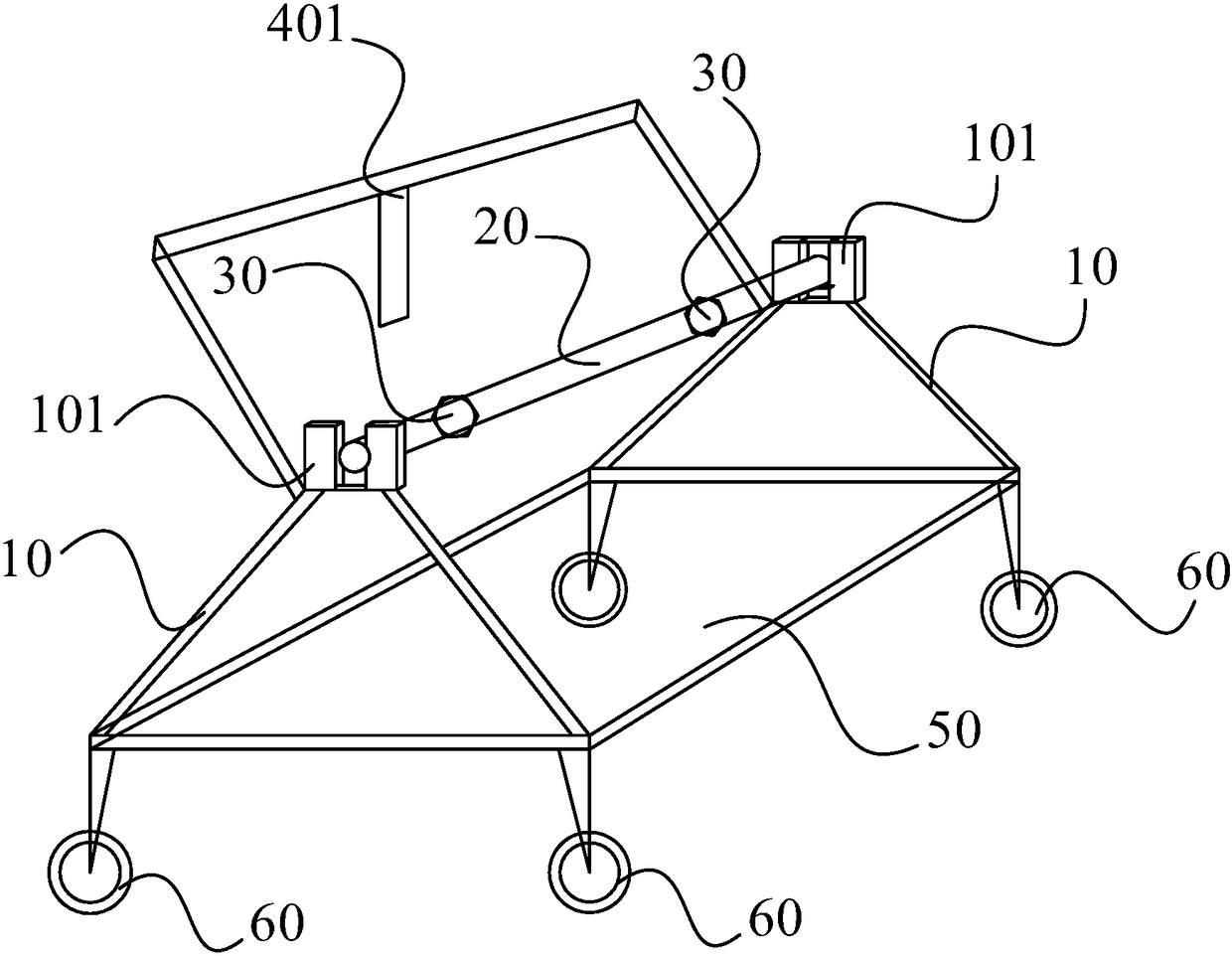

[0042] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0043] This embodiment discloses a laying tool, the laying tool is used for laying glass fiber cloth for the main beam of the wind power blade, refer to figure 1 It should be understood that the laying tool includes two supporting frames 10 , a connecting shaft 20 and a driving member (not shown in the figure) disposed opposite to each other. Wherein, the top of the support frame 10 has a support block 101, and the two ends of the connecting shaft 20 correspond to the two supporting blocks 101, the connecting shaft 20 is used to pass through the reel of the glass fiber cloth, and the driving member is used to act on The outlet end of the fiberglass cloth. Wherein, in this embodiment, the driving member is a motor.

[0044] In this embodiment, the reel of glass fiber cloth is sleeved on the connecting shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com