Device for automatically correcting feeding angle

An automatic correction and loading technology, which is applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of high personnel operation requirements and low efficiency, so as to save operation time, improve production efficiency, and reduce the problem of glass fragments Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

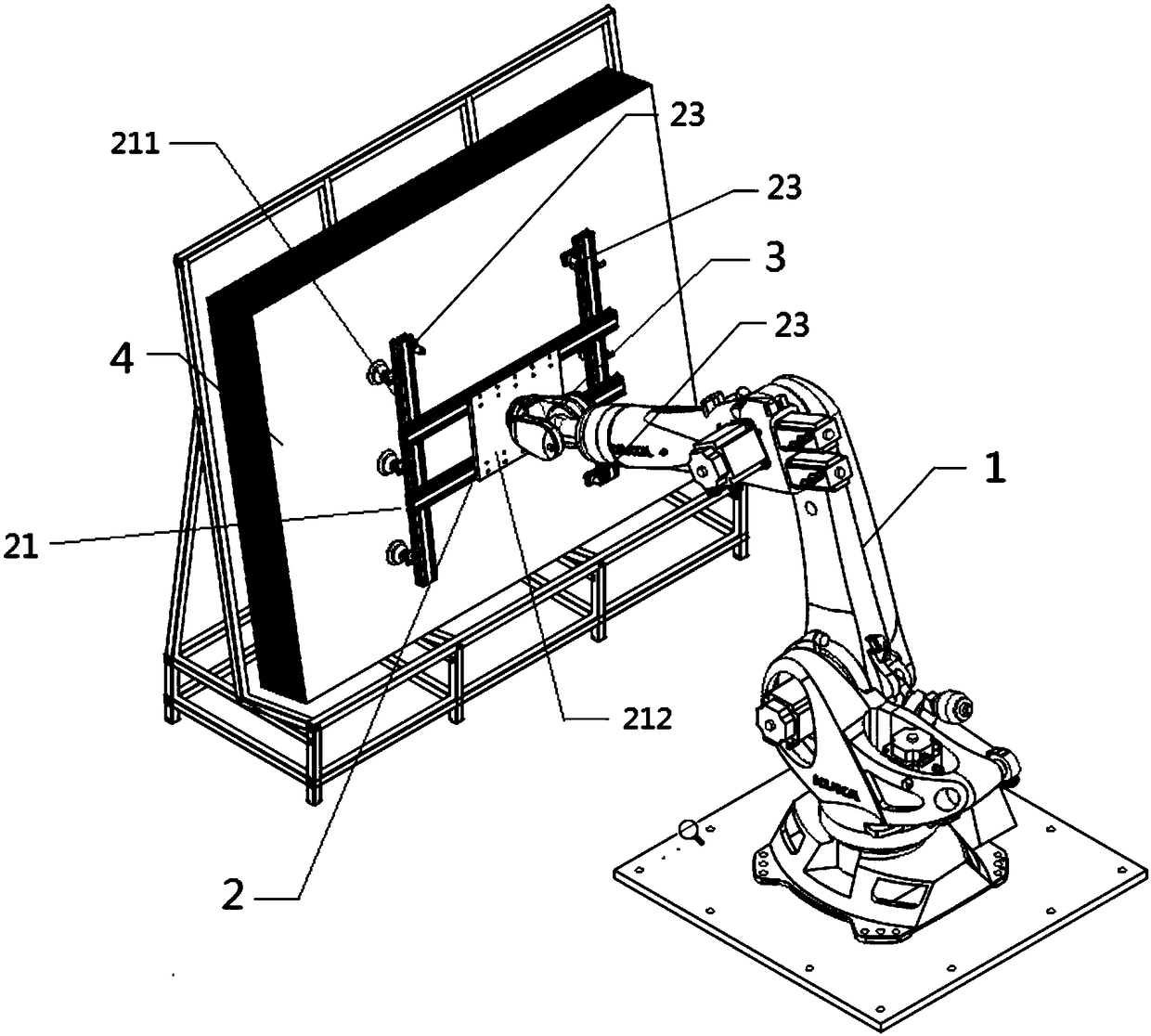

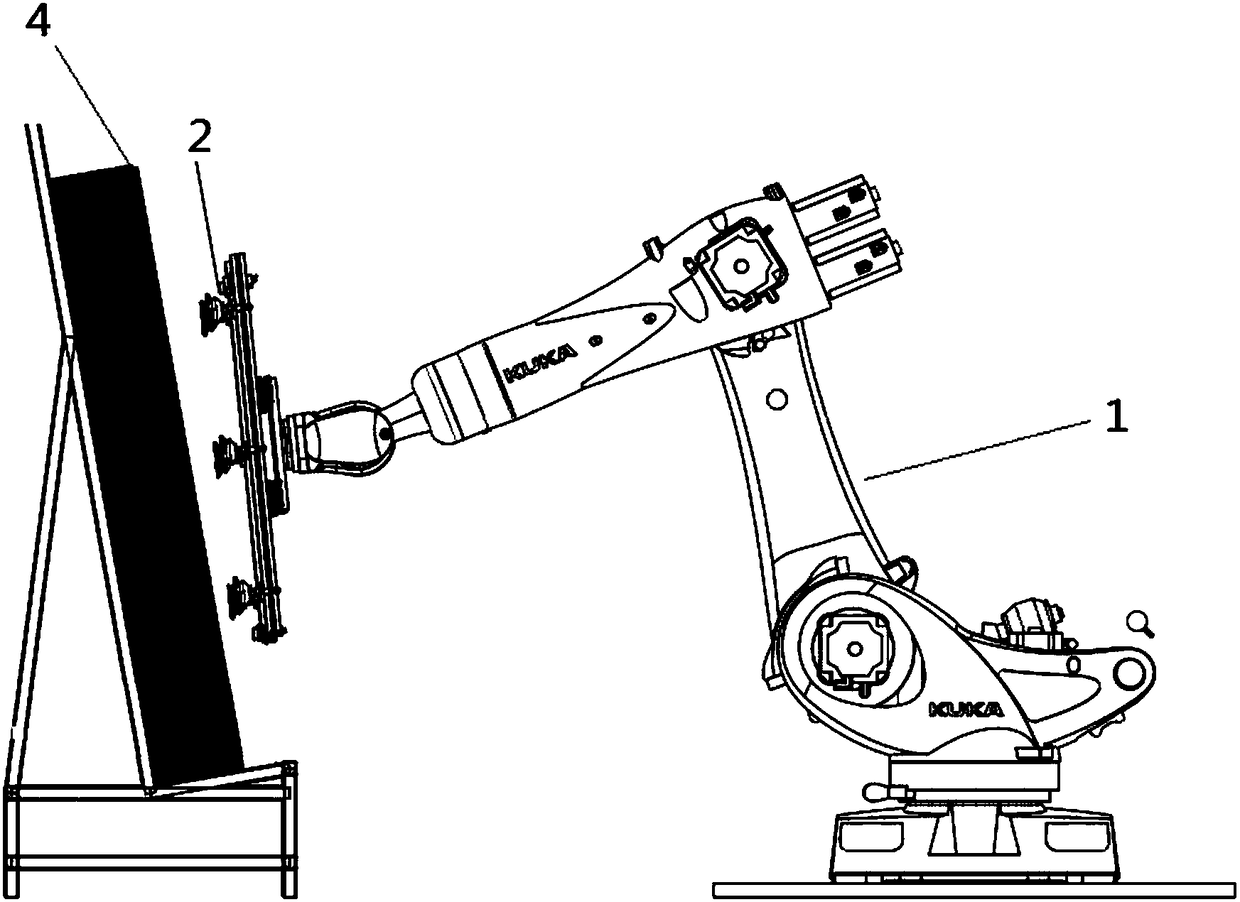

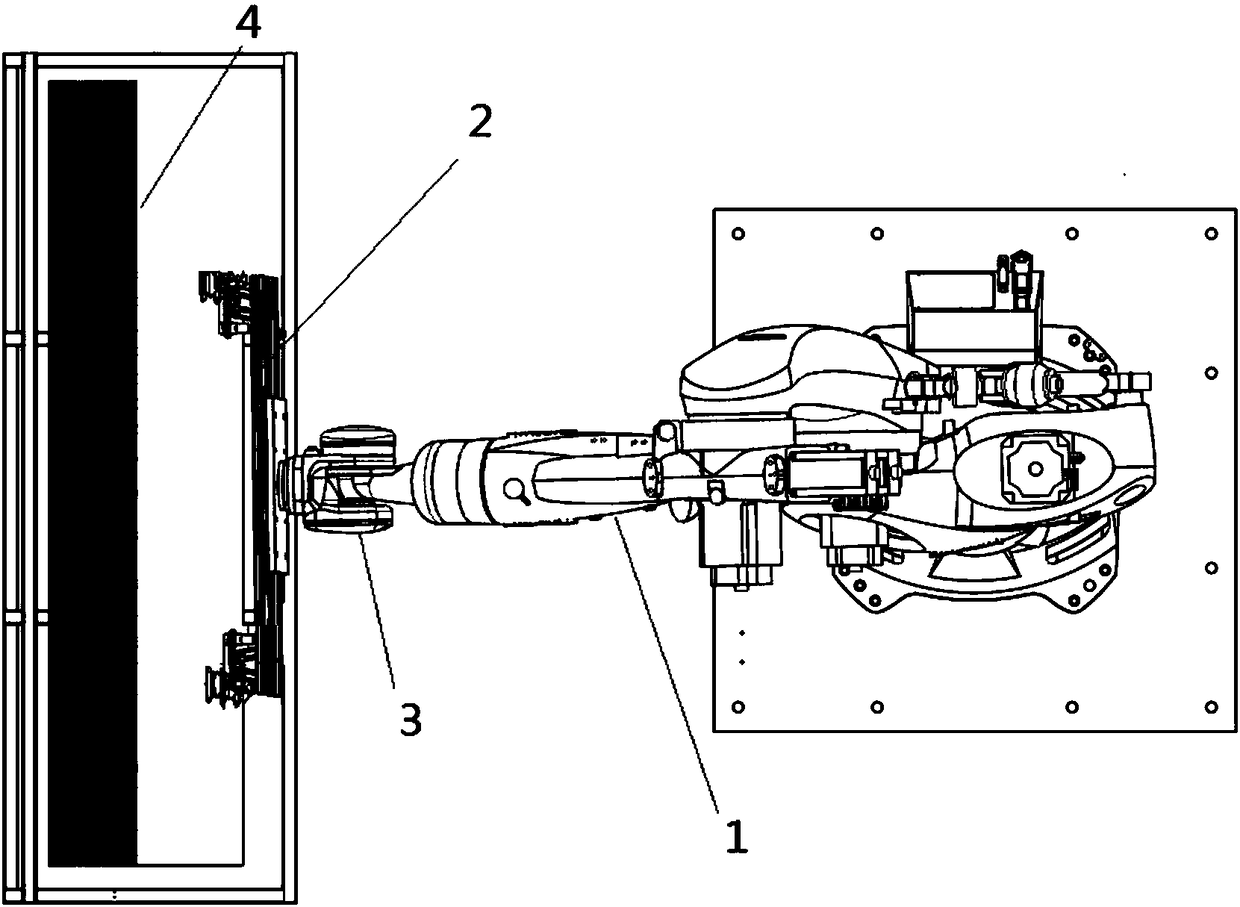

[0030] A device for automatically correcting the angle of film loading, its structure see figure 1 As shown, it includes an industrial robot 1 and a loading mechanism 2 that is arranged on the free end of the industrial robot 1 and is driven by it. The loading mechanism 2 includes a plane suction cup bracket 21 that is movably connected with the industrial robot 1 at the middle part, and drives the plane suction cup bracket 21 to rotate. With the driving assembly for adjusting the angle of the upper film, and the controller for controlling the operation of the driving assembly, the plane suction cup support 21 is I-shaped, and it includes two suction cup rods 211 located on the left and right sides and relatively parallel, between the two suction cup rods 211 It is fixed by a support rod 212 movably connected with the industrial robot 1 , and three suction cups 22 are respectively arranged on the two suction cup rods 211 .

[0031] Adopt movable seat 3 to connect between suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com