Full-automatic discharge bagging machine

A material bagging, fully automatic technology, which is applied in the field of automatic feeding and bagging machinery, can solve the problems of packaging bag sealing, high requirements on packaging bag shape and surface condition, and inability to be reliably sucked, so as to solve the speed bottleneck, The effect of saving labor and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

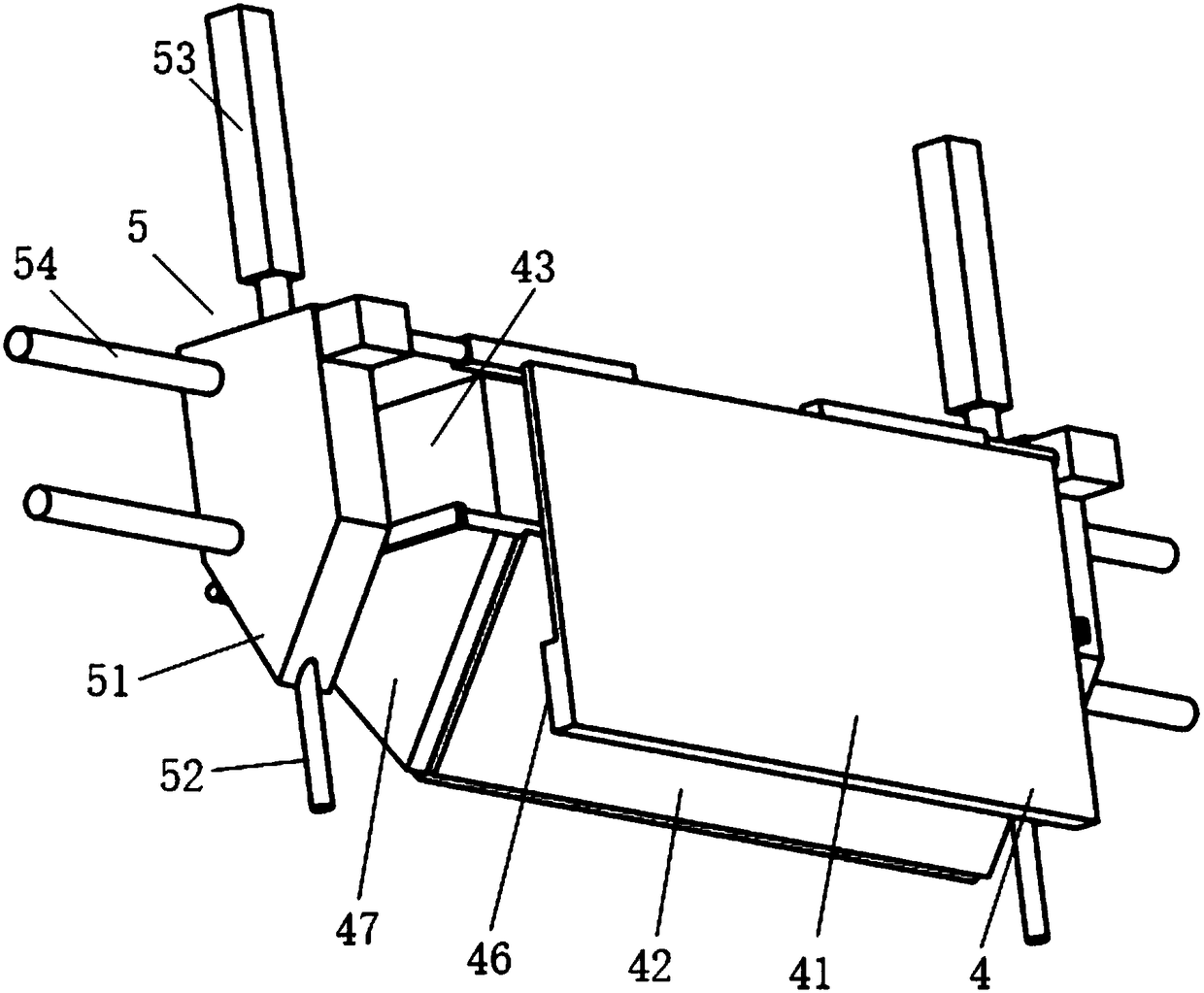

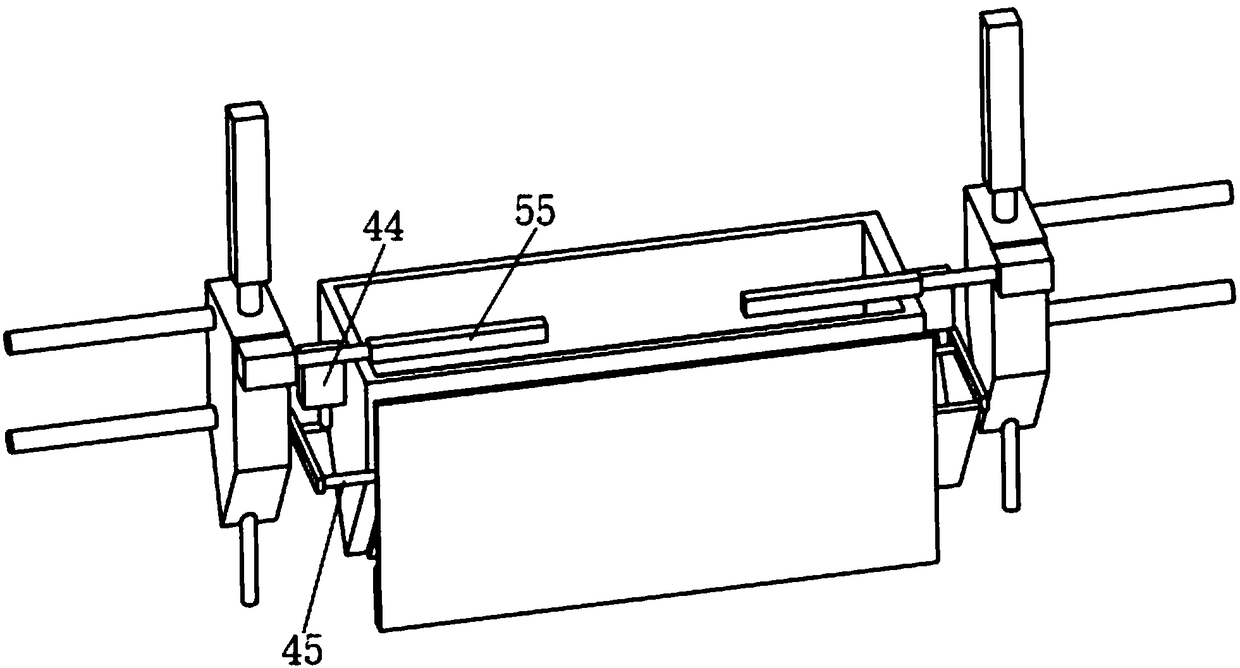

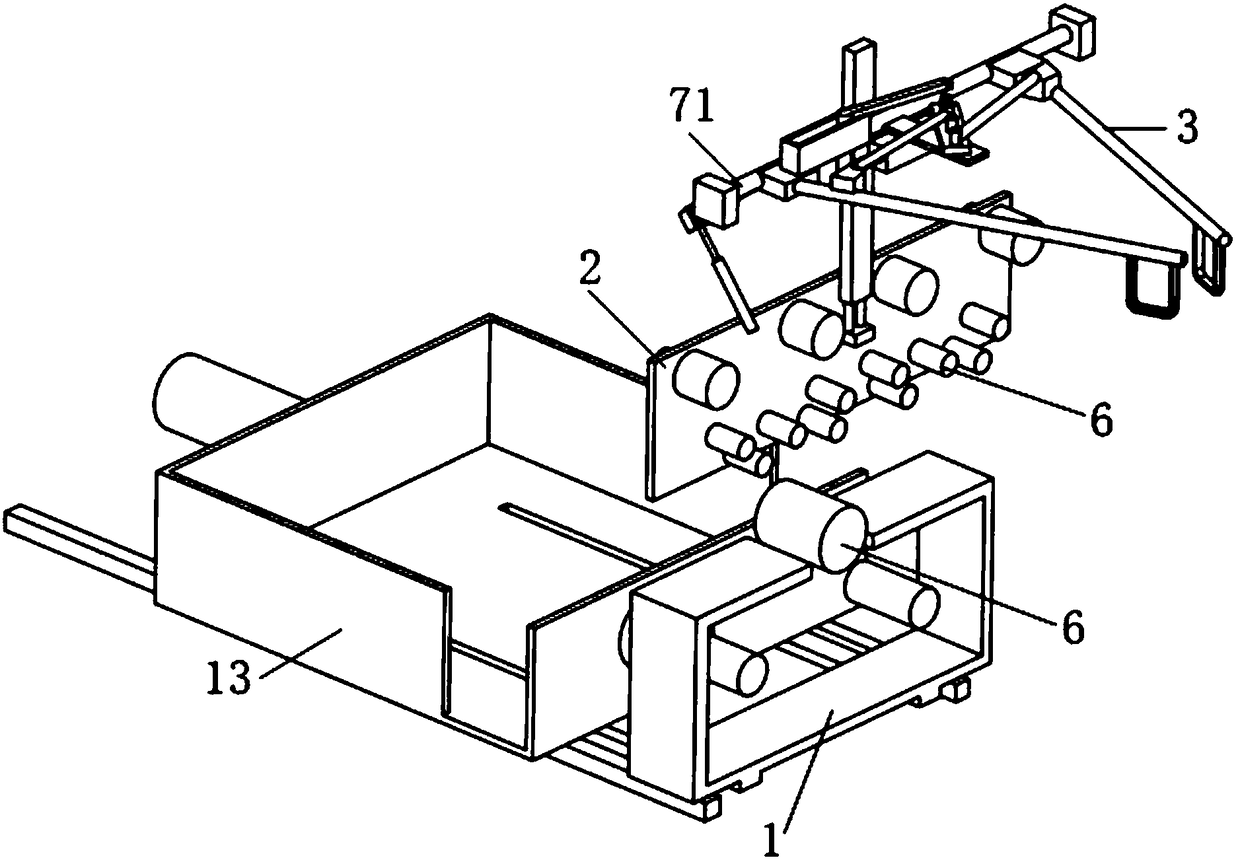

[0042] According to the second embodiment of the present invention, the fully automatic unloading and bagging machine includes an automatic bag opening mechanism, a bag mouth clamping mechanism 4, a bag mouth closing mechanism 5 and a bagged material transmission mechanism arranged in sequence.

[0043] combine Figure 3-Figure 7 , the automatic bag opening mechanism includes a lower opening mechanism 1, an upper opening mechanism 2 and a bag taking arm 3, and a bag storage unit 13 is fixed behind the lower opening mechanism 1, and the bag storage unit 13 can follow the lower opening mechanism 1 move back and forth; the upper mouth opening mechanism 2 is located above the lower mouth opening mechanism 1; the upper mouth opening mechanism 2 is located on the longitudinal movement mechanism 14, and can move up and down under the drive of the longitudinal movement mechanism 14; the lower mouth opening mechanism 1 and The upper opening mechanism 2 is provided with a glue mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com