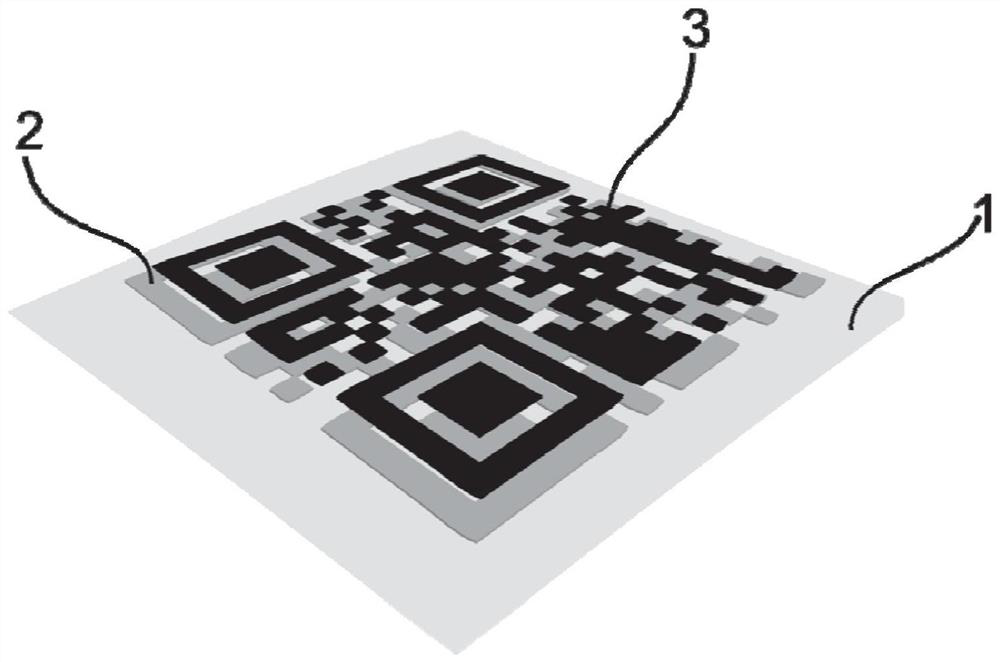

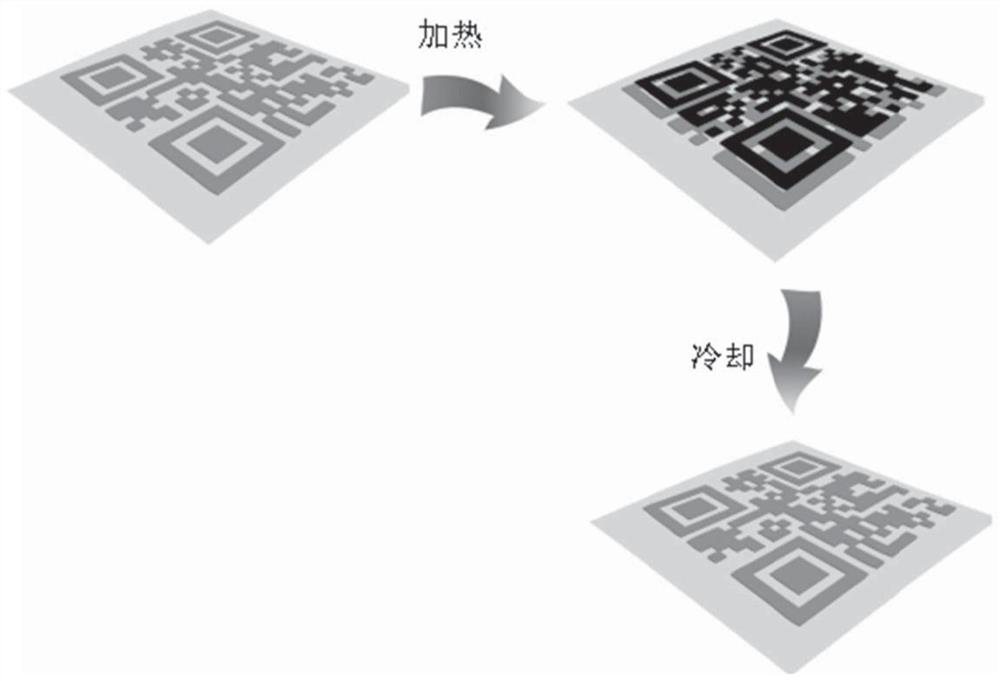

A reverse thermochromic overprint double-layer display two-dimensional code and its preparation method

A thermochromic, two-dimensional display technology, used in instruments, inks, computing, etc., can solve the problems of consumer economic loss of two-dimensional codes, and achieve the effect of enhancing anti-counterfeiting effect, wide range of materials, and convenient application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The preparation of reversible reverse thermochromic microcapsules that are colorless at room temperature and turn green when heated, the specific steps are as follows:

[0058] (1) Take 3,3-bis(4-diethylamino-2-ethoxyphenyl)-4-azaphthalide and lauric acid in a mass ratio of 1:10, mix and stir evenly, and heat at 120°C Completely melt, and stir the melted mixture into pulverization to obtain the microcapsule core material;

[0059] (2) After mixing melamine powder and 37wt% formaldehyde solution at a mass ratio of 1:4, reacting magnetic stirring in an oil bath at 75° C. for 2 hours, and using triethanolamine to adjust the system pH=8.5 to obtain a microcapsule core wall solution;

[0060] (3) Keep the temperature of the prepared microcapsule core material at 70°C, add 400mL water containing 1.0wt% xanthan gum, use a homogenizer to emulsify for 5min, and keep the temperature at 70°C at a shear rate of 5000r / min; the emulsification ends Finally, add the microcapsule core ...

Embodiment 2

[0063] The preparation of reversible inverse thermochromic microcapsules that are colorless at room temperature and turn black when heated, the specific steps are as follows:

[0064] (1) Take 2-phenylamino-3-methyl-6-dibutylaminofluorane and stearic acid, mix and stir evenly at a mass ratio of 1:10, heat and melt completely at 150°C, and stir the melted mixture into Pulverize to obtain the microcapsule core material;

[0065] (2) After mixing melamine powder and 37wt% formaldehyde solution at a mass ratio of 1:4, reacting magnetic stirring in an oil bath at 75° C. for 2 hours, and using triethanolamine to adjust the system pH=8.5 to obtain a microcapsule core wall solution;

[0066] (3) Keep the temperature of the prepared microcapsule core material at 70°C, add 400mL water containing 1.0wt% xanthan gum, use a homogenizer to emulsify for 5min, and keep the temperature at 80°C at a shear rate of 5000r / min; the emulsification ends Finally, add the microcapsule core wall soluti...

Embodiment 3

[0069] The preparation of the transparent reverse thermochromic ink that is colorless at room temperature and turns green when heated, the specific steps are as follows:

[0070] The colorless heating black ink at room temperature is composed of 3,3-bis(4-diethylamino-2-ethoxyphenyl)-4-azaphthalide reverse thermochromic microcapsules, additives and solvents, In terms of mass percentage, the specific ingredients and formula ratio are:

[0071] 10% of reverse thermochromic microcapsules prepared in Example 1, toluene 18%, emulsified silicone oil 1%, Sylgard184A58%, polyacrylamide 5%, curing agent Sylgard 184B 3% and acrylic resin 5%;

[0072] After mixing the components evenly, stir mechanically at room temperature for 30 minutes, and let it stand for 30 minutes to obtain a colorless ink at room temperature that turns green when heated, which is designated as A ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com