Methods and apparatus for clutch and brake drag reduction using springs

A technology of clutches and clutch components, applied to parts of brakes, clutches, friction clutches, etc., can solve problems such as low mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

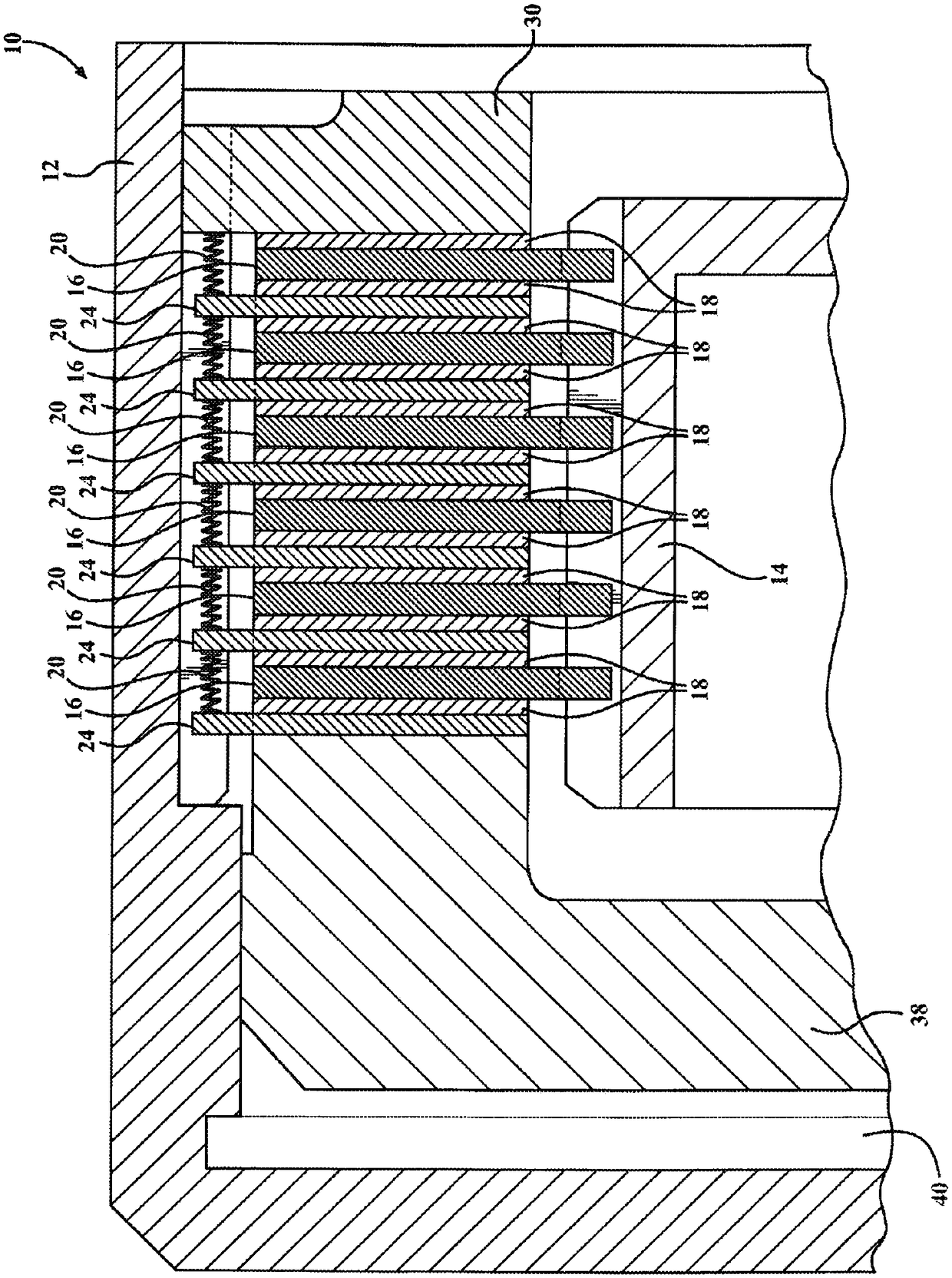

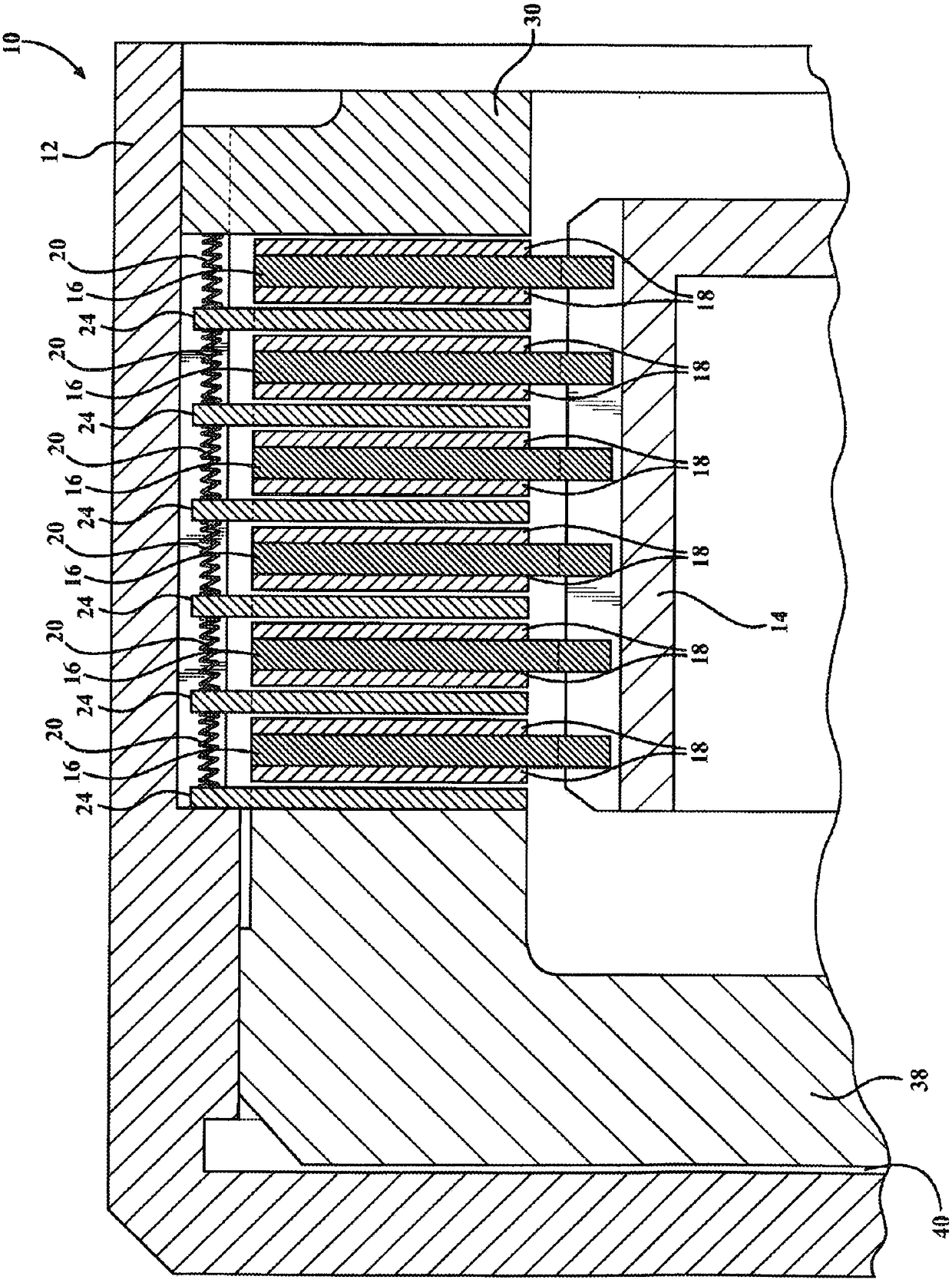

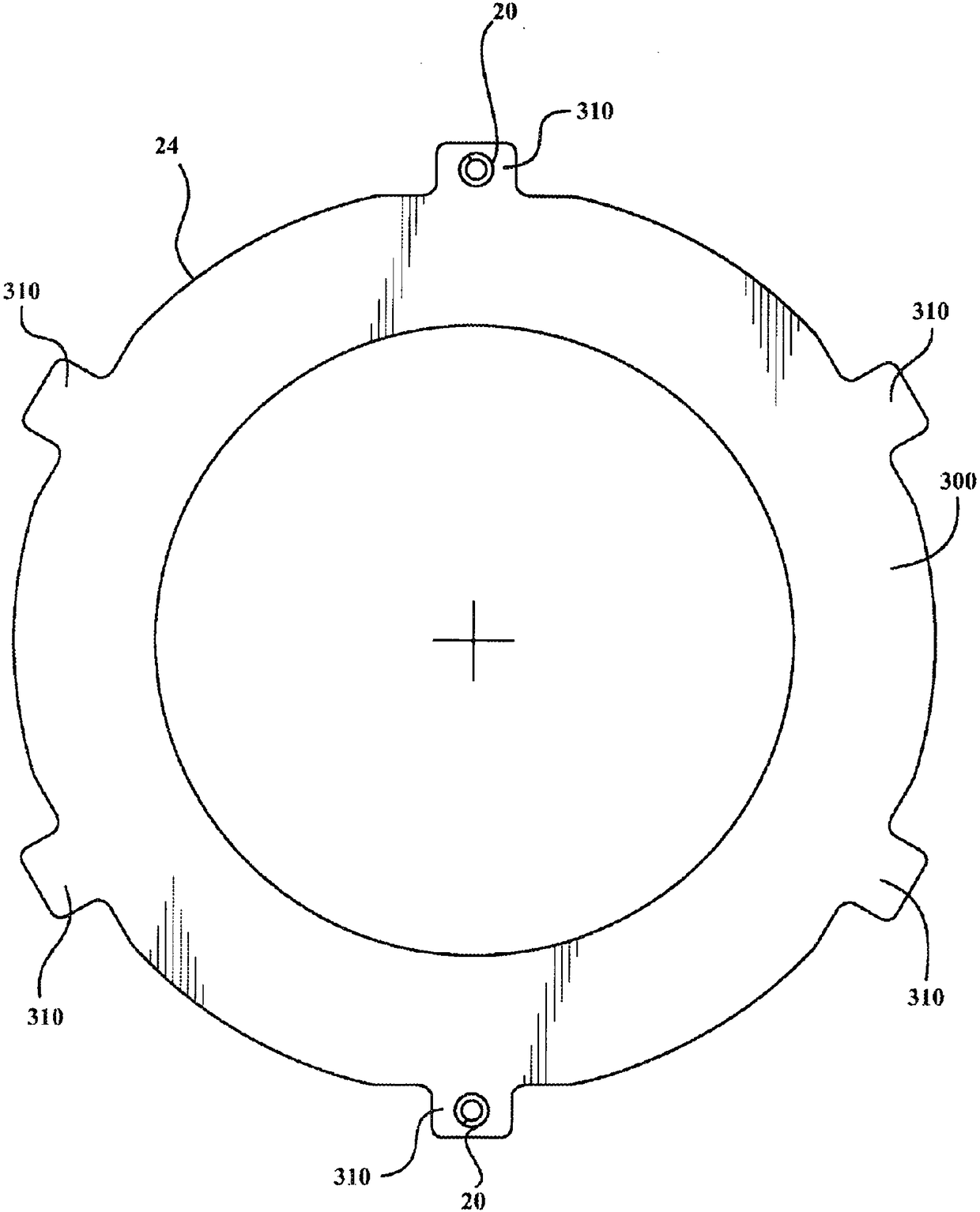

[0016] Embodiments described herein relate to clutch assemblies and separator plates for clutch assemblies. Each of the separator plate embodiments includes one or more springs therein. As used herein, a spring may include any mechanism (eg, a helical coil or mesh) or material (eg, rubber) that can be compressed or pulled and then return to its previous shape. The spring may be mounted on or in the first divider plate adjacent to the second divider plate. This arrangement creates a repulsive separation force between adjacent divider panels. When the clutch pack is in the open condition, this disengagement force pushes the adjacent separator plates apart, thereby helping to separate the separator plates from the clutch friction plates when the clutch is disengaged.

[0017] The present disclosure is described in detail with reference to the accompanying drawings which form a part hereof. In the drawings, similar reference symbols typically identify similar components, unless...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com