Large-size LCD face overturning device

A large-scale, flip-up technology, used in transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of indentation, easy crushing, slow speed, etc., to reduce the distribution of lines and pipes, stable and safe operation , the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

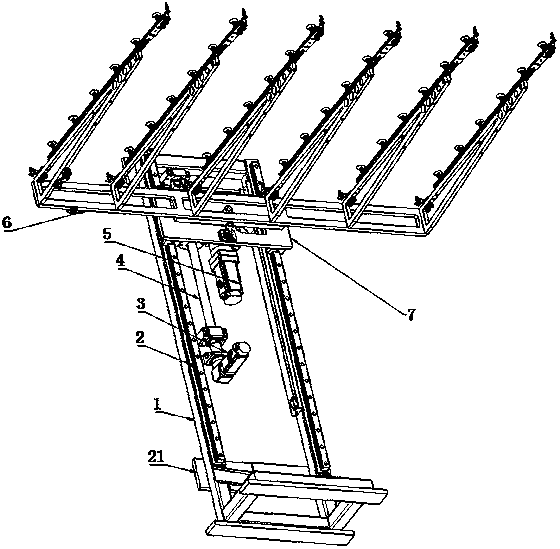

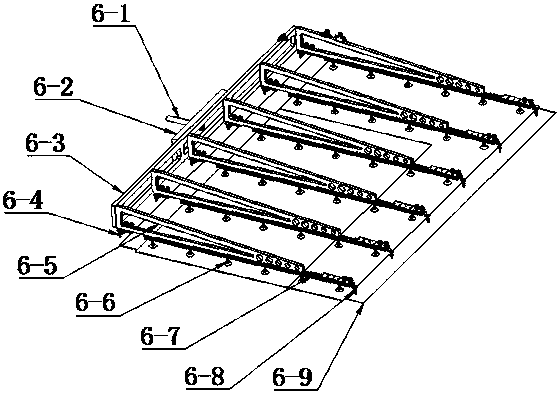

[0018] see figure 1 , figure 2 , a large-size LCD turning mechanism, including steel structure welding bracket (1), guide rail (2), lifting servo motor and reducer (3), transmission screw, turning servo motor and reducer, turning mechanism ( 6), Turn over the moving block (7), the steel structure welding bracket (1) is under the guide rail (2), the guide rail (2) is installed on the steel structure welding bracket (1) and Located under the turning block (7), the lifting servo motor and reducer (3) are fixed below the turning block (7) through a transmission screw and between the two guide rails (2). The overturning servo motor and reducer are fixed directly below the overturning moving block (7), and the overturning mechanism (6) is fixed above the overturning moving block (7) and used for tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com