Pressure-bearing pipeline plugging device

A technology for sealing devices and pressure-bearing pipes, which is applied in the direction of special pipes, pipe components, pipes/pipe joints/fittings, etc., and can solve problems such as pollution at the plugging hole, long-term stable plugging, and leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

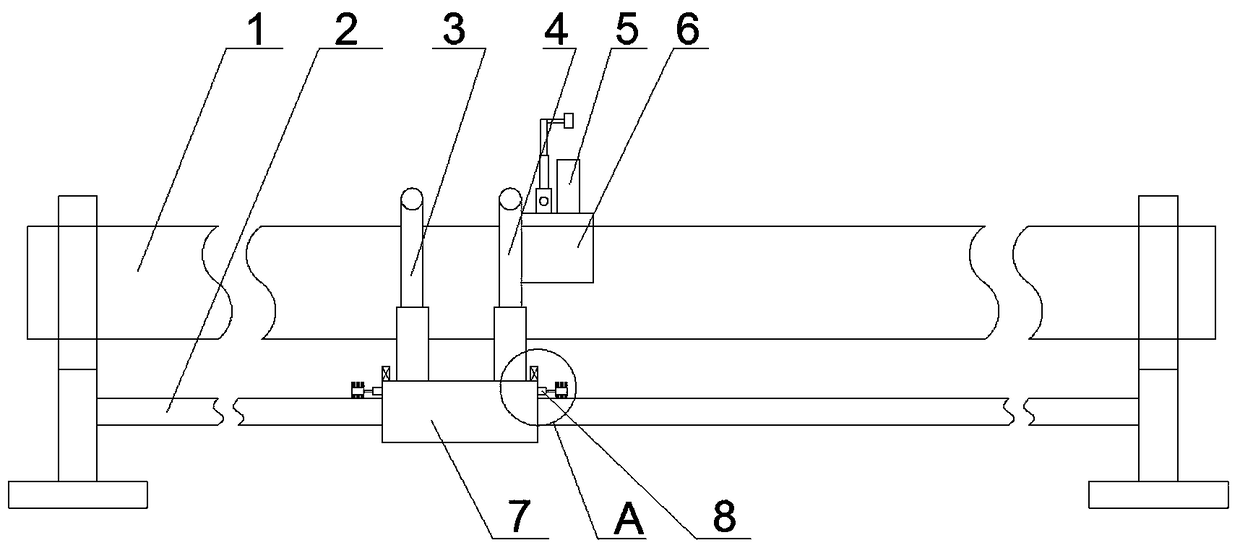

[0064] A pressure-bearing pipeline blocking device, comprising a traveling mechanism 7 arranged on a fixed base at the end of a pressure-bearing pipeline 1, an inspection mechanism 3 arranged on the traveling mechanism 7, and a traveling mechanism 3 arranged on the traveling mechanism The blocking mechanism 4 on the 7 and matched with the inspection mechanism 3, and the control mechanism arranged on the running mechanism 7 for controlling the running mechanism 7, the inspection mechanism 3 and the blocking mechanism 4;

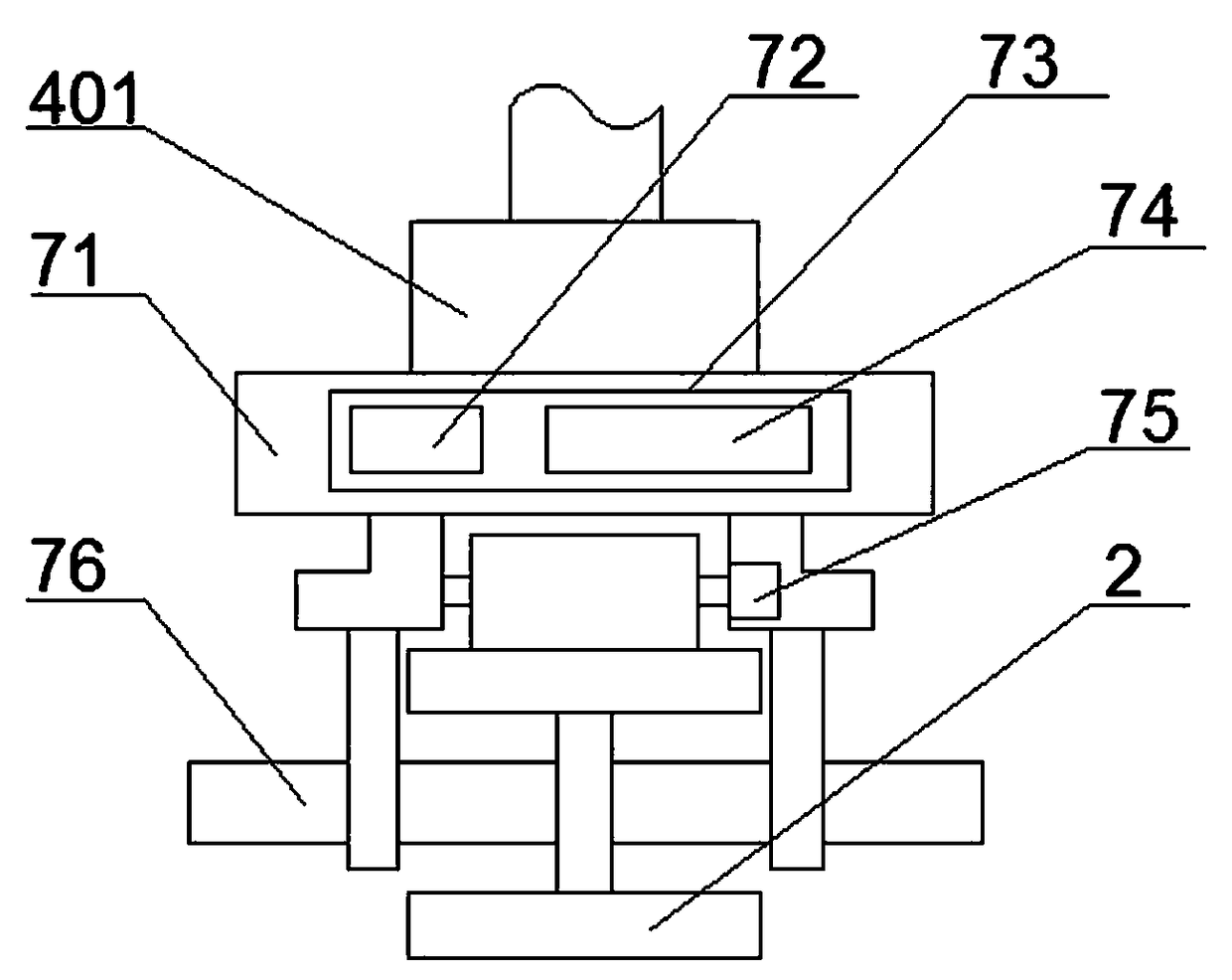

[0065] The traveling mechanism 7 includes a traveling track 2 connected to the fixed base of the pressure pipeline 1, a traveling trolley 71 arranged on the traveling trolley 2, arranged on the lower part of the traveling trolley 71 and the traveling trolley 2 A plurality of driving wheels 76 that cooperate, the driving motor 75 that cooperates with described driving wheel 76, is arranged on described walking dolly 71 and is used for cleaning mechanism 8 that w...

Embodiment 2

[0080] The difference from Embodiment 1 is that: a sealing ring matching with the upper end of the sealing tube 5 is provided on the peripheral side of the operation boss 414 .

[0081] It is arranged on the blocking support plate 409 and a multi-layer sealing ring 417 is arranged around the blocking hole 423 .

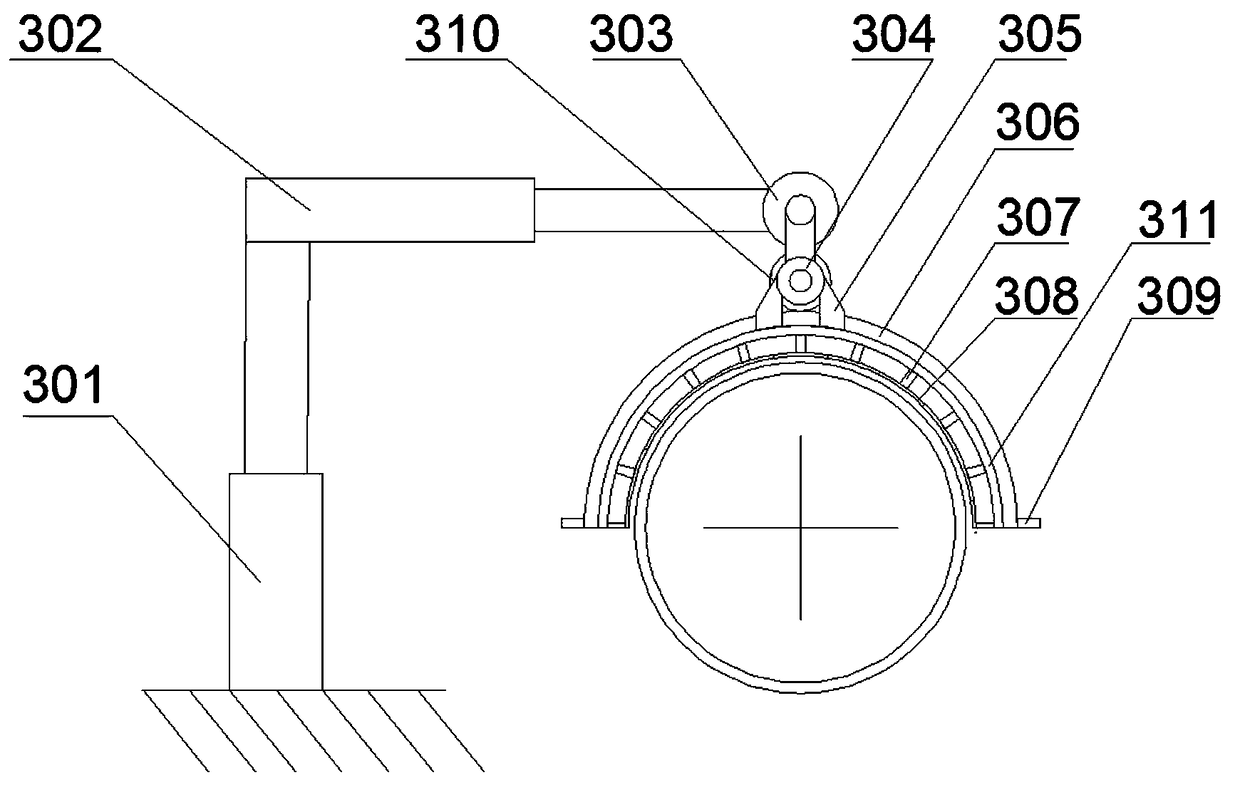

[0082] The radius value of the circle where the arc-shaped blocking guide rail 306 and the arc-shaped inspection guide rail 408 are located is greater than the radius value of the circle on the outer wall of the cross-section of the pressure pipe 1 .

[0083] The arc formed by the arc-shaped blocking guide rail 306 and the arc-shaped inspection guide rail 408 is a semi-circular arc.

[0084] The threaded surface of the sealing plug 4223 is provided with a graphite sealing coating.

Embodiment 3

[0086] The difference from the first embodiment is that the first driving wheel 310 is a helical gear.

[0087] The threaded surface of the sealing plug 4223 is provided with a layer of sealing tape wrapped around it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com