Low-thrust ripple long primary permanent magnet synchronous linear motor

A permanent magnet synchronous linear, low-thrust technology, applied to electrical components, electromechanical devices, propulsion systems, etc., can solve problems such as large thrust fluctuations, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

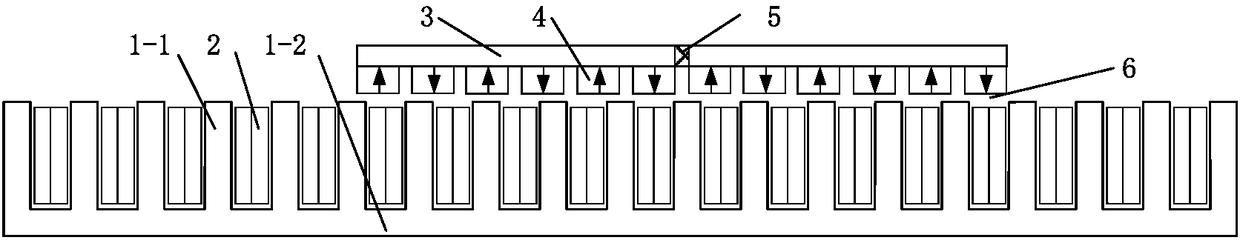

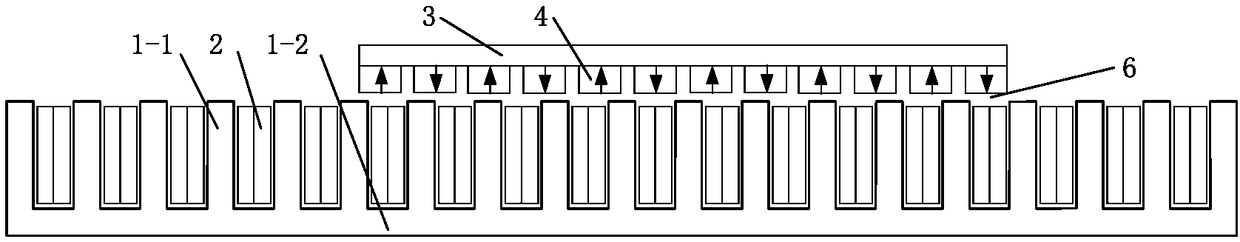

[0016] Such as figure 1 As shown, the low-thrust fluctuation long-primary permanent magnet synchronous linear motor adopts a 9-slot and 12-pole structure, including primary components and secondary components. The primary assembly acts as a stator and consists of a primary iron core (1) and an armature winding (2). The longitudinal length of the primary assembly is much greater than that of the secondary assembly. A primary iron core (1) made of laminated silicon steel sheets is slotted, and the iron core (1) is divided into a tooth portion (1-1) and a yoke portion (1-2) after the slotting. The primary iron core (1) has 18 slots in total, and the armature winding (2) is arranged in the slot. The armature winding (2) adopts a double-layer centralized type, and the coils are connected in the order of A-X-B-Y-C-Z.

[0017] The secondary assembly is used as a mover, which is composed of a permanent magnet (4) and a secondary iron core (3). The permanent magnet (4) is magnetized a...

Embodiment approach 2

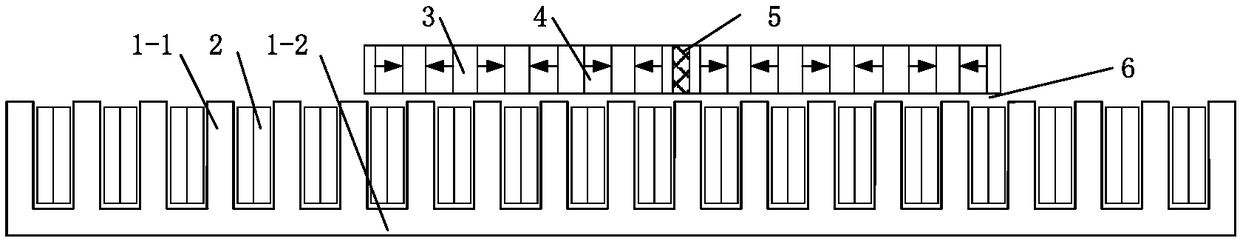

[0020] The difference between this embodiment and Embodiment 1 is: as image 3 As shown, the permanent magnet (4) of the motor adopts an embedded structure, the permanent magnet (4) is magnetized along the longitudinal direction, and is distributed alternately with the secondary iron core (3). The width of the magnetic isolation region (5) in the middle of the secondary iron core is smaller than the width of the pitch of the permanent magnets (4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com