All-black polycrystal high-efficiency photovoltaic assembly and manufacturing method thereof

A technology of photovoltaic modules and manufacturing methods, which is applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve problems such as low efficiency, use of black modules, and blue color of polycrystalline photovoltaic modules, and achieve the effect of improving module power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

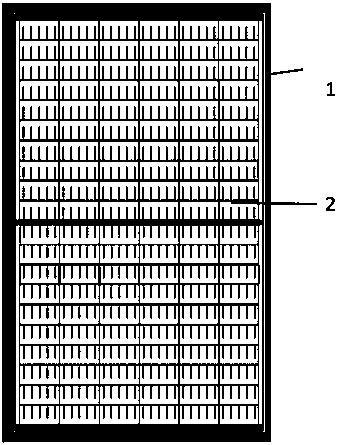

[0016] An all-black polycrystalline high-efficiency photovoltaic module, including polycrystalline black silicon cells and a frame 1, and also includes: a photovoltaic laminate 2, which is clamped with the frame 1; the photovoltaic laminate 2 includes: a coated glass layer, connected to the first Bonding of the encapsulation film layer; the first encapsulation film layer, bonded to the solar cell layer; the solar cell layer, bonded to the second encapsulation film layer; the second encapsulation film layer, bonded to the backplane; , snapped into frame 1.

[0017] The solar cell layer includes: a bus bar, bonded to the solar cell strings; several solar cell strings, connected in series through the bus bars, bonded to the first encapsulation adhesive film layer and the second encapsulation adhesive film layer.

[0018] The solar cell string includes: interconnection bars 4 welded to solar cells 5 ; several solar cells 5 connected in series through interconnection bars 4 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com