Method for testing real viscosity of rubber asphalt and equipment of method

A technology for rubber asphalt and viscosity, applied in the field of measuring the real viscosity of rubber asphalt, can solve problems such as the inability to truly and accurately express the viscosity of rubber asphalt, uneven rotor friction, uneven test results, etc., to achieve large-scale application and save heat preservation. Time, environmental benefits and win-win effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

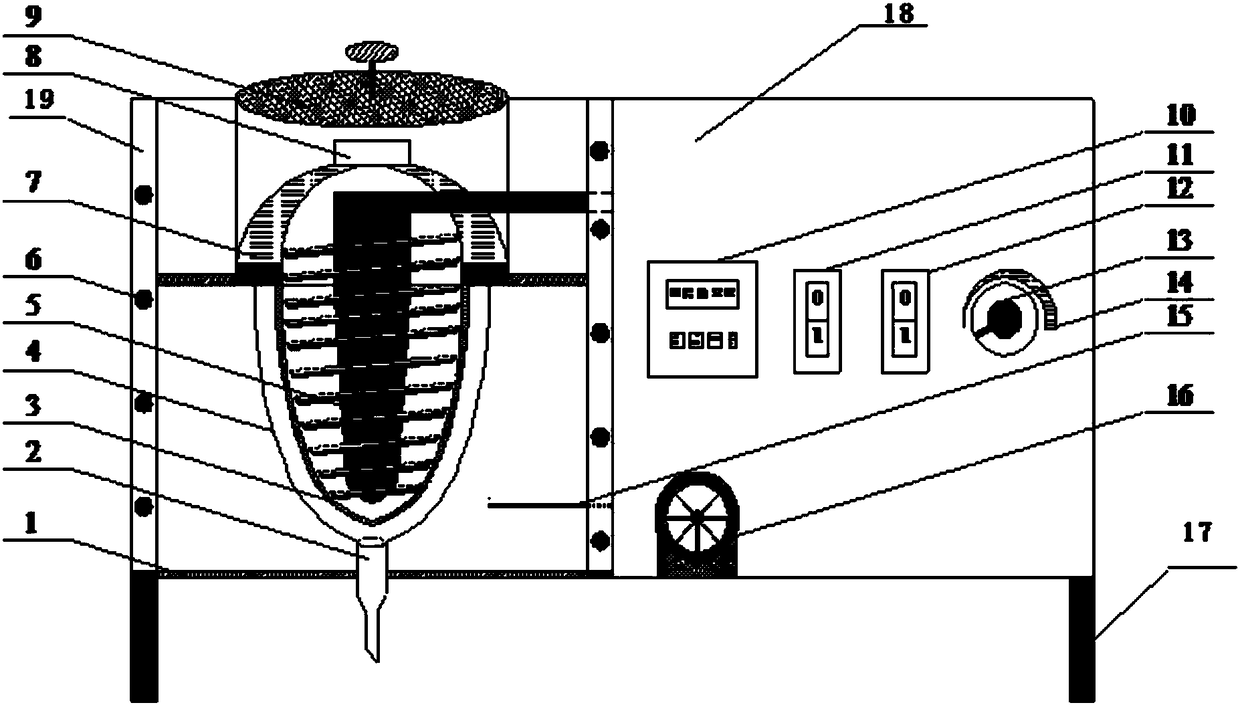

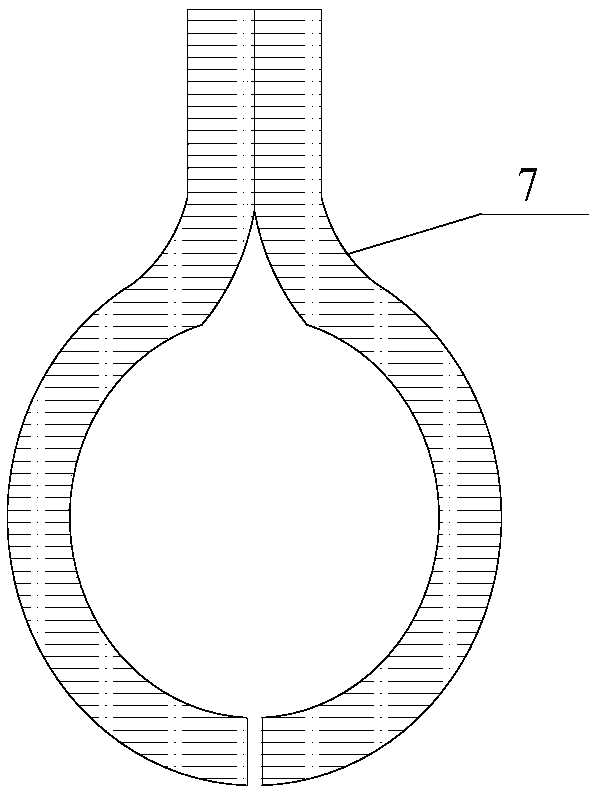

[0035] Such as figure 1 , 2 As shown, the present invention discloses a device for measuring the true viscosity of rubber asphalt, which includes a bracket 18, a leg 17, a twitchable bottom plate 1, a drainage tube 2, a 200-mesh filter screen 3, a metal shell 4, a wide threaded rotor 5, a heating Rod 6, conveyor belt 7, waste port 8, cover 9, temperature control and digital display area 10, temperature control switch 11, main switch 12, forward and reverse switch 13, speed regulator 14, temperature sensor 15, motor 16 , the four corners below the bracket 18 are provided with legs 17, the left part of the bracket 18 is provided with a housing 19, the side wall of the housing 19 is provided with a plurality of heating rods 6, and the inside of the housing 19 An ellipsoidal metal shell 4 is provided, and an ellipsoidal filter screen 3 is located at the inner center of the ellipsoidal metal shell 4. A wide-threaded rotor 5 is arranged inside the ellipsoidal-shaped filter screen 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com