Electroplate liquid stirring device

A technology of stirring device and stirring shaft, which is applied to mixers with rotating stirring devices, accessories of mixers, transportation and packaging, etc., can solve the problems of increasing the resistance of stirring, reducing the stirring effect, and not scraping, and reducing the resistance. , Improve stirring efficiency and stirring effect, and enhance the effect of stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

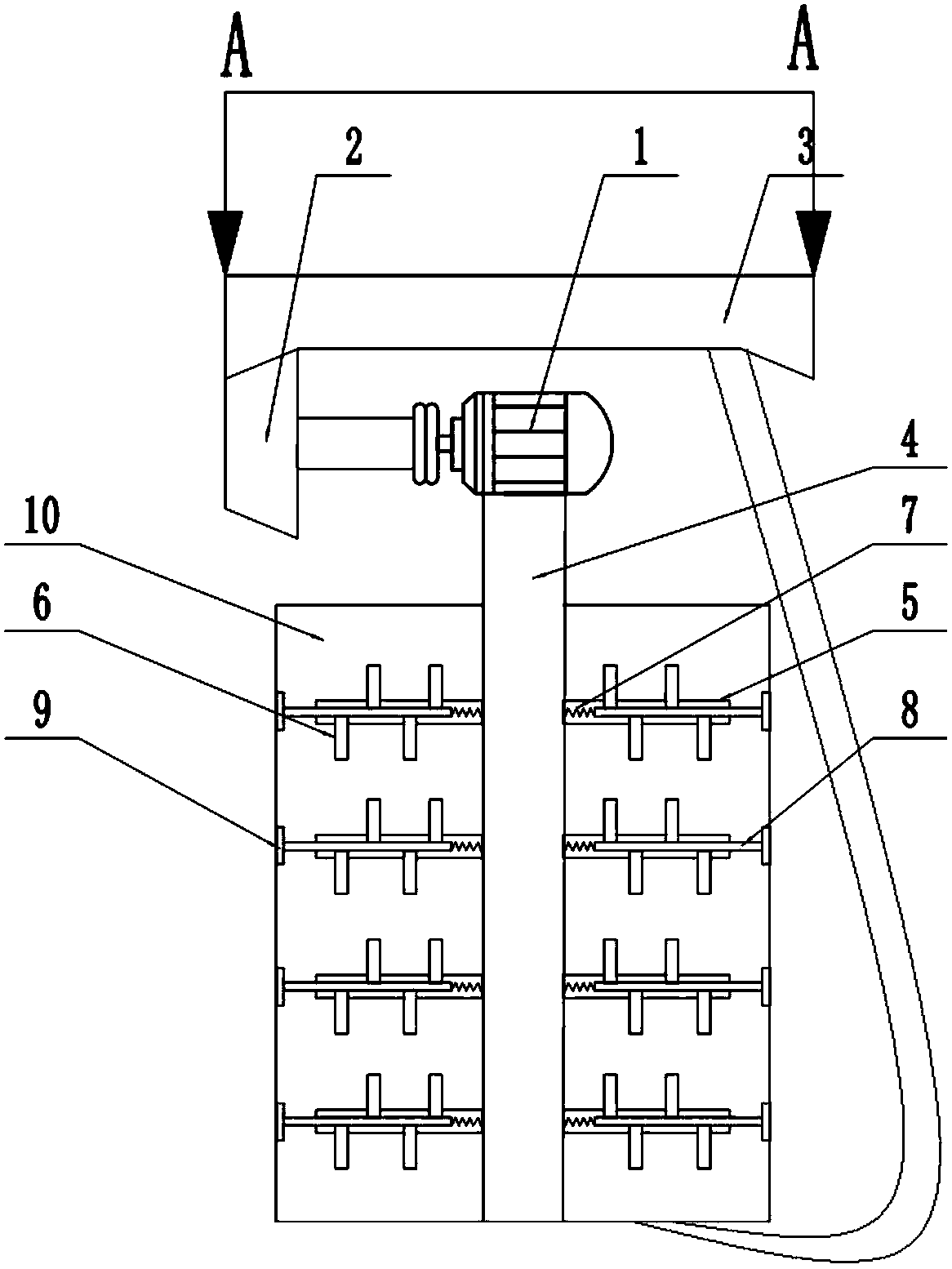

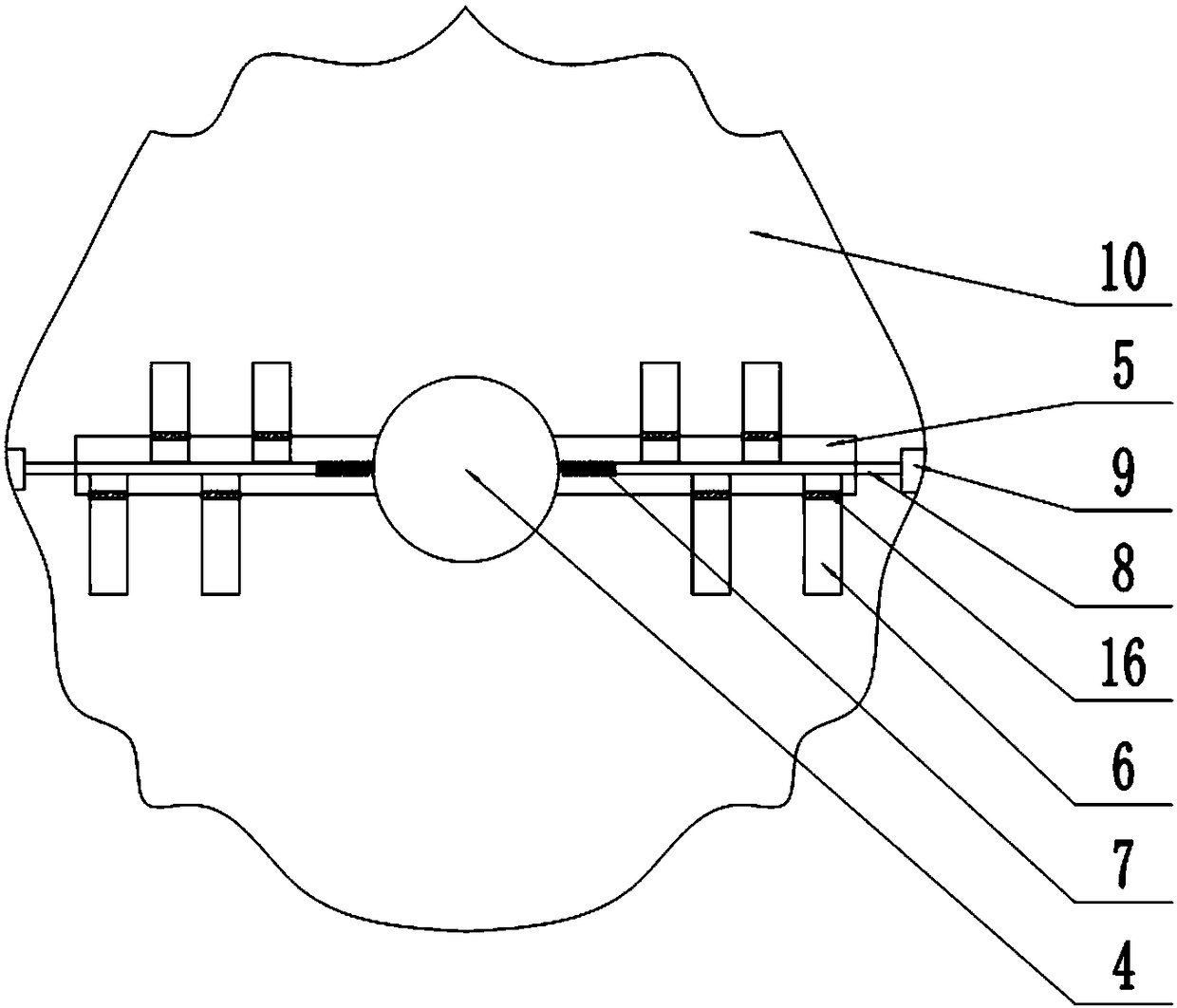

[0021] Instructions attached Figures 1 to 3 The reference signs in include: motor 1, bevel gear 2, gear ring 3, rotating shaft 4, stirring shaft 5, stirring rod 6, spring 7, push rod 8, scraper 9, outer barrel 10, air bag 11, air collection bag 12. Flexible hose 13, air intake one-way valve 14, air outlet one-way valve 15, sealing ring 16.

[0022] Such as figure 1 As shown, a stirring device for electroplating solution includes a frame, an outer barrel 10 and a rotating shaft 4 arranged in the outer barrel 10. The inner wall of the outer barrel 10 is irregularly concave-convex, and the rotating shaft 4 is rotationally connected with a plurality of laterally arranged The stirring shaft 5 is vertically arranged between the stirring shaft 5 and the rotating shaft 4, and a plurality of vertically arranged stirring rods 6 are arranged at intervals on the stirring shaft 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com