Overall formwork system for structure missing layer and construction method thereof

A construction method and overall technology, applied in the field of formwork/formwork/work frame, preparation of building components on site, building construction, etc., can solve safety problems, unfavorable construction operations and other problems, and achieve easy disassembly and recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

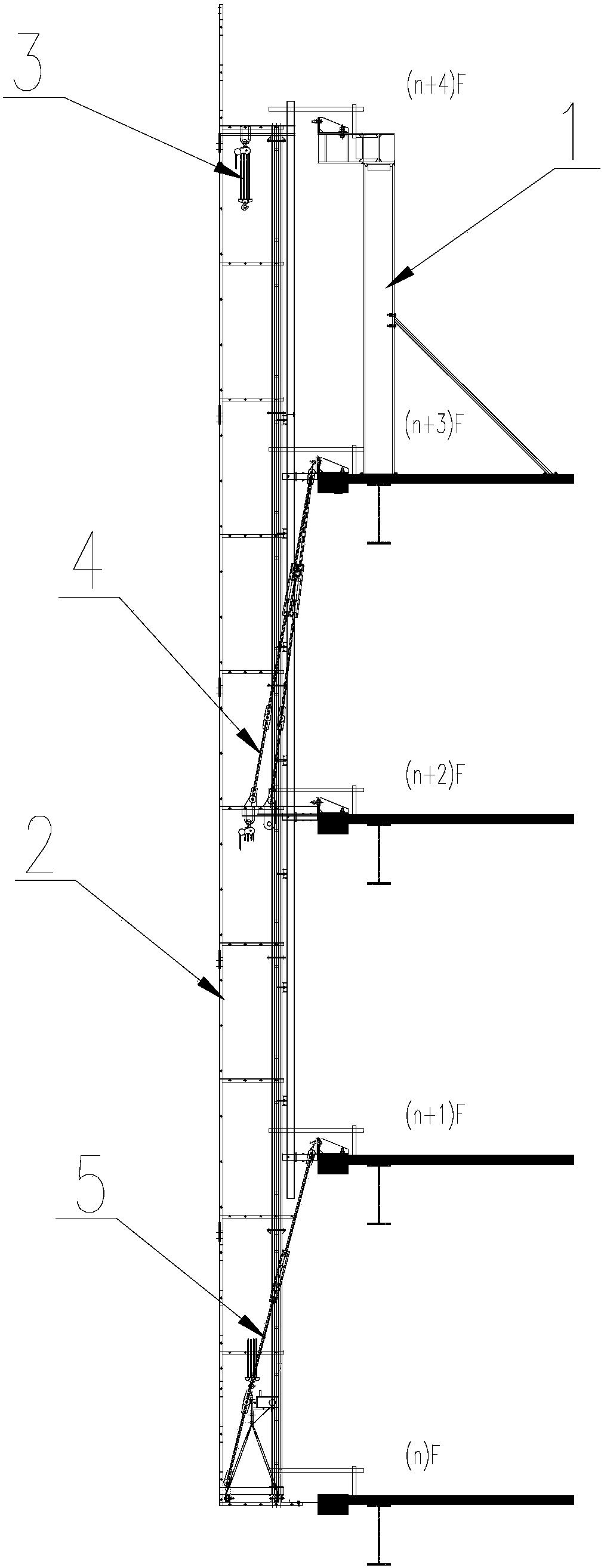

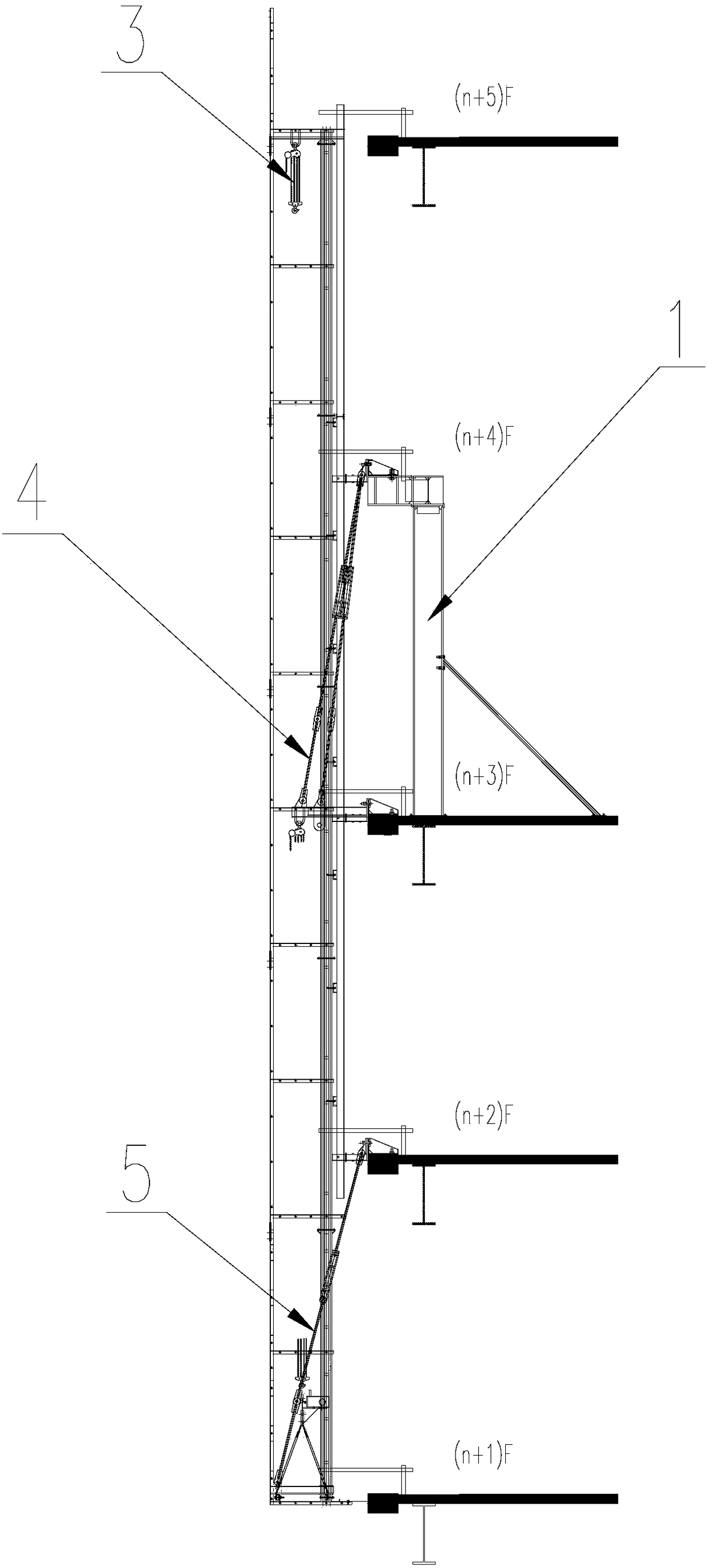

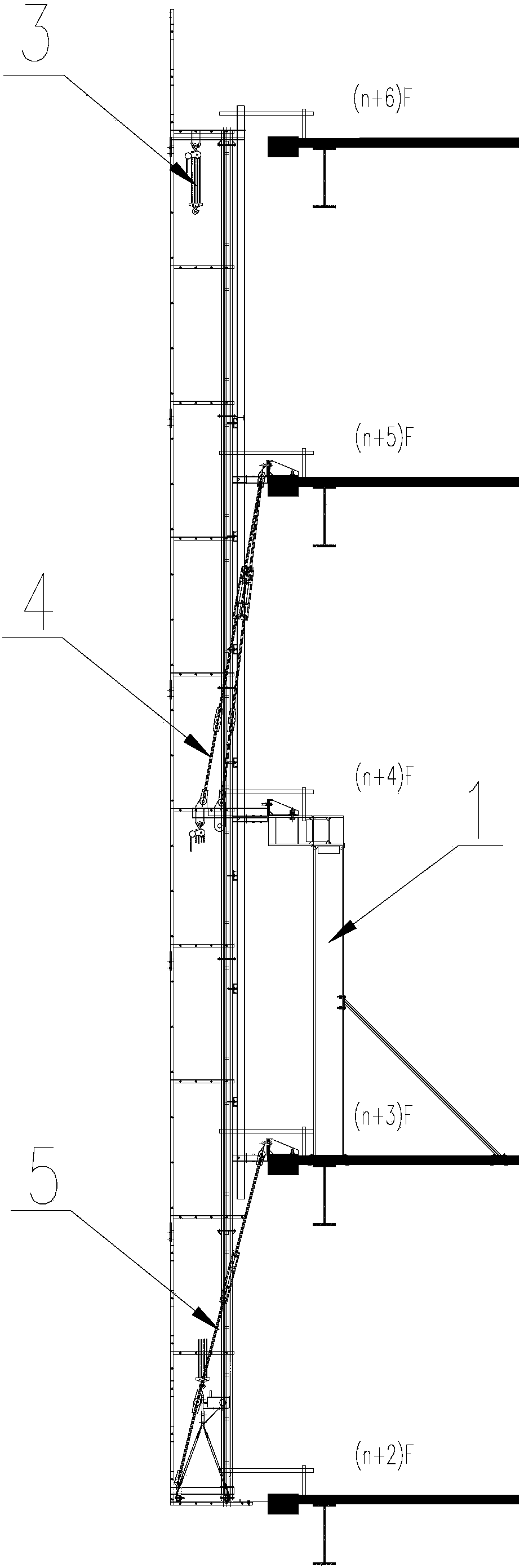

[0046] Example: refer to figure 1 , Figure 7 to Figure 12 As shown, the integral formwork system for structurally missing floors of the present invention includes an attachment and fixing device 1 installed on the next floor of the structural missing layer, and a climbing form installed on the permanent structure of the building and the attachment and fixing device 1 Rack 2.

[0047]The climbing formwork 2 of the present invention covers four floor heights, and the four floors are respectively (n)F, (n+1)F, (n+2)F, (n+3)F, and the (n+4)th ) F floor is the first structure-missing floor, and the (n+8)th F floor is the second structure-missing floor; the top of the climbing formwork 2 is provided with a reversible pedal 21, and on the top of the climbing formwork 2, the reversible pedal One side of 21 is equipped with a hoisting mechanism 3 (here the hoisting mechanism 3 adopts an electric hoist), and the steel beam located on the top of the climbing formwork 2 and used to han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com