High narrow large orifice intake gate water draining method and device

A technology for water intake gates and orifices, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of increasing the uneconomical opening and closing capacity and increasing project investment, so as to reduce the opening force, save investment, The effect of increasing the exhaust velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

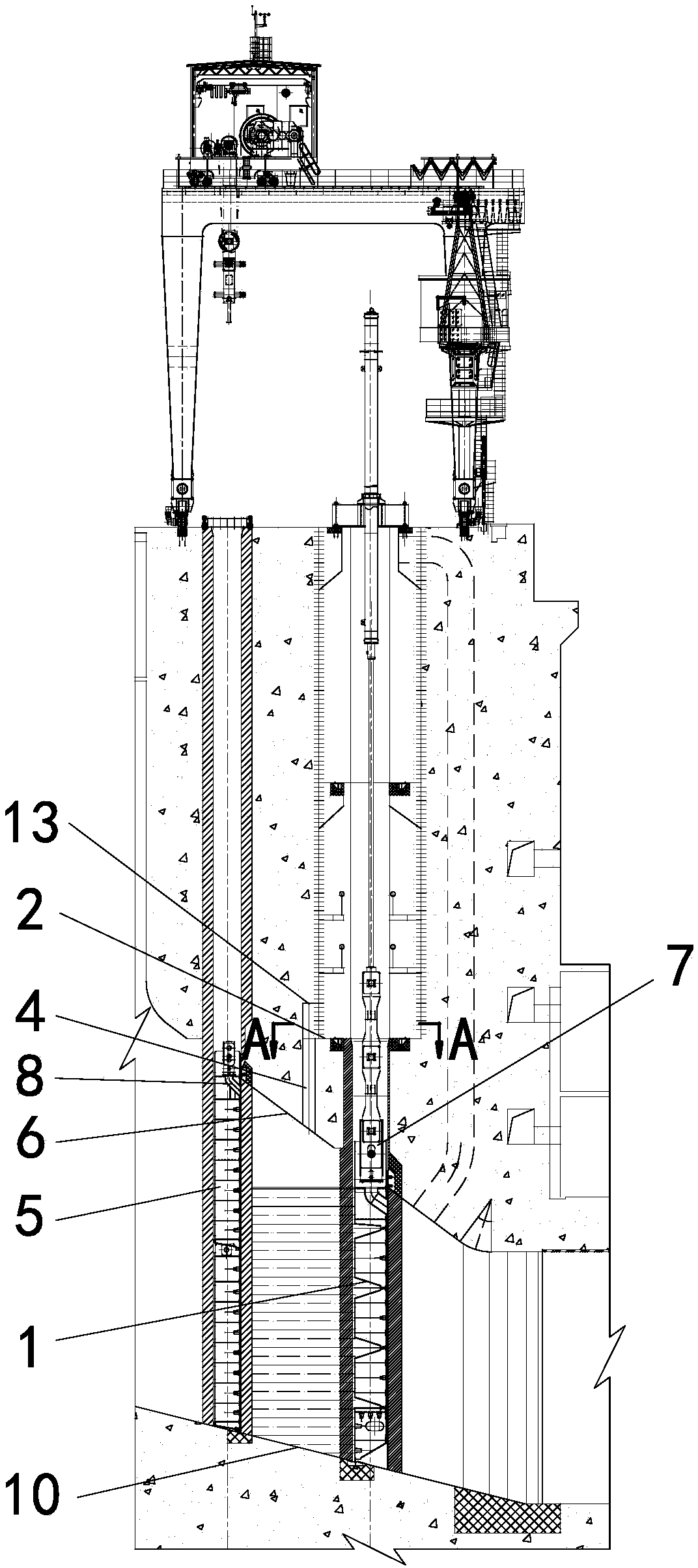

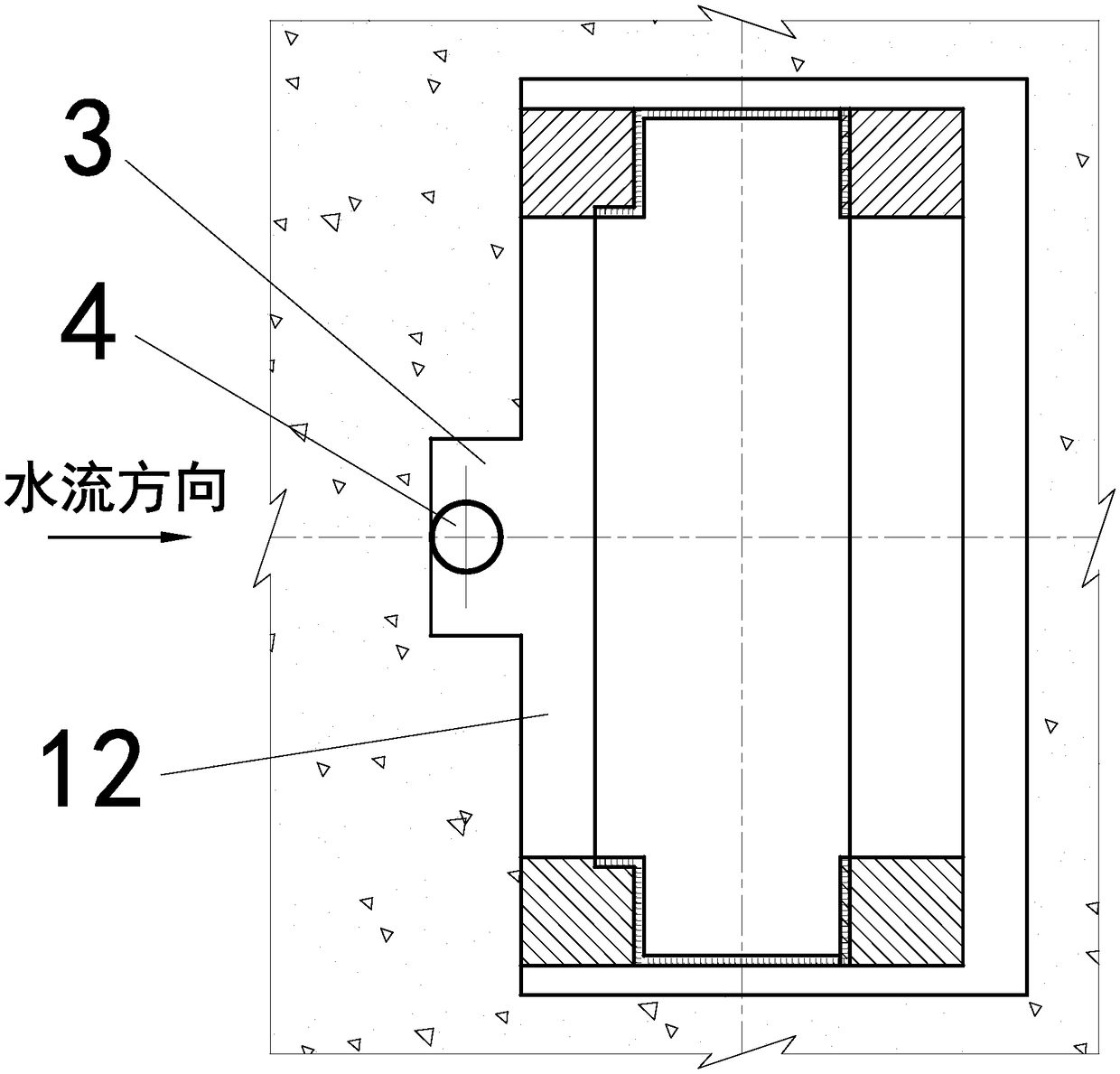

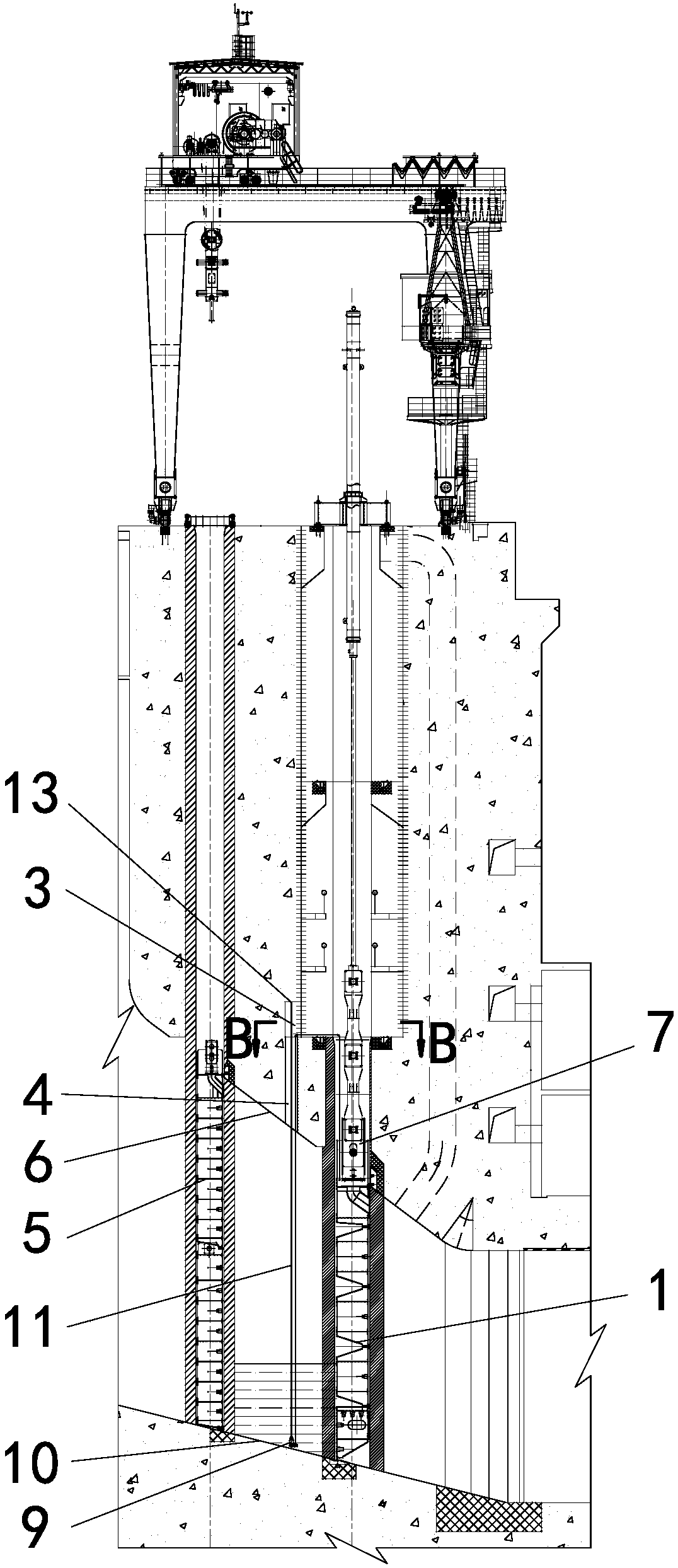

[0023] Examples of the present invention are Figure 1~4 As shown, a rectangular groove 3 is opened in the middle of the upstream side of the maintenance platform 2 of the water inlet gate 1, and a circular hole 4 is set at the lower part of the rectangular groove 3 to lead to the flow channel between the lower maintenance gate 5 and the water inlet gate 1. Top 6. When the water inlet gate 1 utilizes its top water filling valve 7 to discharge water to the water inlet of the water filling valve 7, the temporary submersible pump 9 is placed on the bottom sill 10 between the maintenance gate 5 and the water inlet gate 1 through the circular hole 4, Use the temporary submersible pump 9 to pump the remaining water between the maintenance gate 5 and the water inlet gate 1 to the water inlet of the water filling valve 7 of the water inlet gate 1, and discharge the water to the dam body through the water outlet of the water filling valve 7 of the water inlet gate 1 Downstream; the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com