A rapid drying device and a control method

A technology of fast drying and drying device, applied in the field of clothes dryers, can solve the problems of increasing the thickness of clothes in the middle, different lengths of clothes, and difficulty in drying clothes, etc., and achieves the effect of preventing clothes from slipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

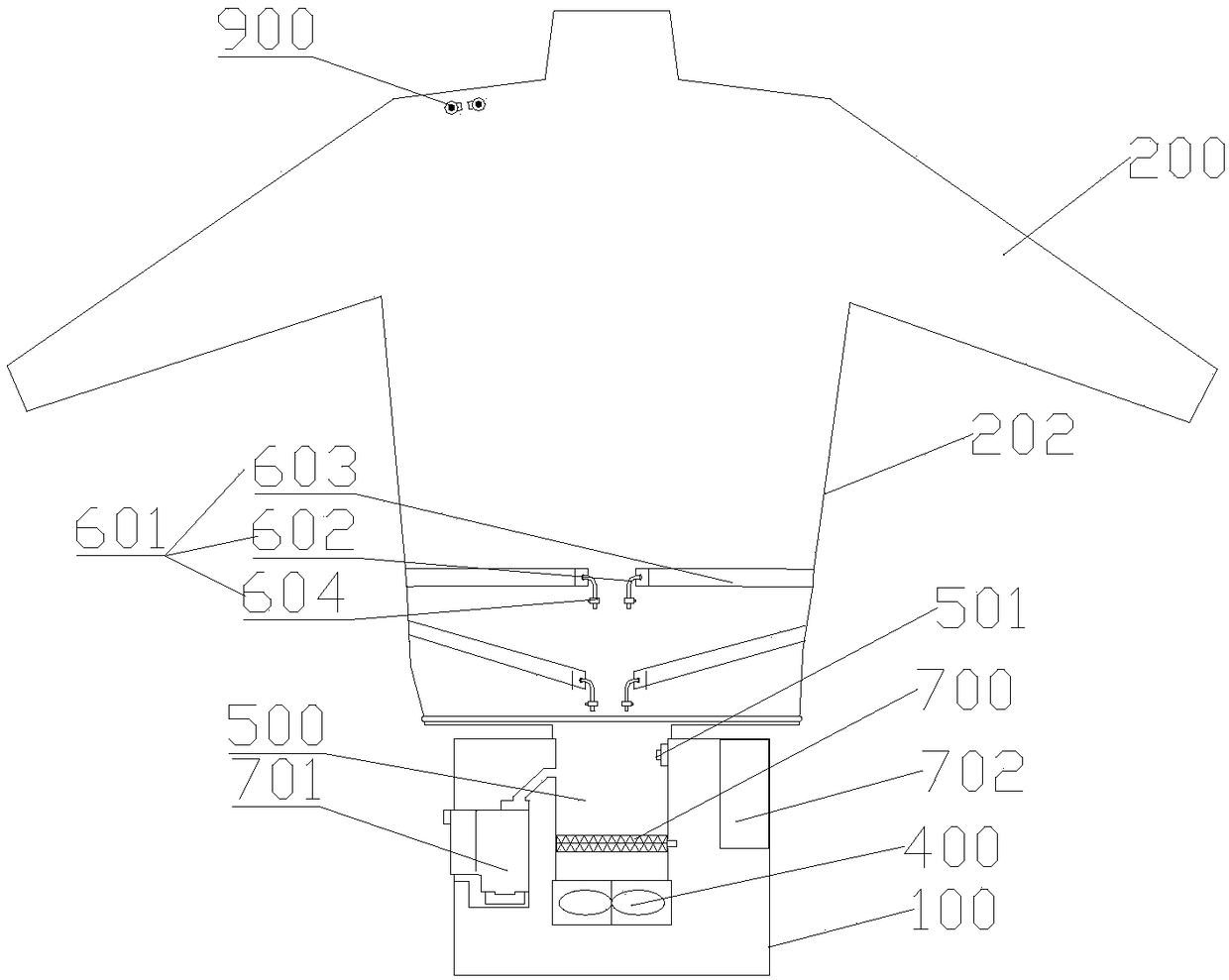

[0050] Such as Figure 1-3 As shown, a quick drying device includes a base 100, an air bag 200 arranged on the base 100 for covering clothes, and a drying device for blowing drying air into the air bag 200. The air bag 200 has a limited Position structure 202, the position-limiting structure 202 prevents the clothes from slipping after the airbag 200 is inflated.

[0051] Since the airbag 200 is soft, after the airbag 200 inflates, the inflation of the airbag exerts a force on the clothes, so that some parts of the clothes are unbalanced by the force of the airbag 200, and the clothes will slip. The sliding action tends to make the clothes pile up, which makes the part difficult to dry. Even if the part is dried for a long time, it will cause the part to form wrinkles; it can be artificially flattened during the drying process, but because the clothes The force on this part is still unbalanced, and slippage will occur.

[0052] By setting the limiting structure 202, the limi...

Embodiment 2

[0061] Such as Figure 1-3 As shown, the present embodiment is a further limitation to Embodiment 1, the airbag 200 is a jacket-shaped airbag 200, the airbag 200 is located below the chest, and the upper circumference of the airbag 200 is greater than the lower circumference.

[0062] Further, the circumference of the airbag 200 below the chest gradually increases from bottom to top, that is, the airbag 200 is in an inverted cone shape.

[0063] Such as figure 1 As shown, the shaded part in the figure is the clothing on the airbag. When the clothing is placed on the airbag 200, the circumference of the airbag 200 below the lower edge of the clothing is smaller than the circumference of the upper airbag 200 adjacent to it. When the airbag After 200 is inflated, the lower part of the clothing fits with the airbag 200, and the airbag 200 located below the lower edge of the clothing produces a relatively small upward component force on the clothing, and the friction force of the...

Embodiment 3

[0072] Such as image 3 As shown, on the basis of Embodiment 1 and Embodiment 2, the airbag 200 of this embodiment also includes a scaling member 601, and the scaling member 601 can shrink the airbag 200 inwardly so that the circumference of its adjacent part is larger than that of this part. The circumference forms a limiting structure 202 .

[0073] By setting the scaling member 601 on the airbag 200, the purpose of partially shrinking the airbag 200 is realized, and the expansion force generated by the airbag 200 on the contracted part is reduced, and the expansion force exerted on the clothing by the adjacent uncontracted part is larger than that The shrinking part exerts a large expansion force on the clothes, and the adjacent non-shrinking parts form a limiting part to balance the clothes.

[0074] Further, the oblique setting of the contraction element has a better effect.

[0075] This method can be applied to the airbag 200 with the limit structure 202 already insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com