Ultra-low overloading bidirectional traction rubber wheel flat car

A technology of two-way traction and flatbed truck, applied in the field of auxiliary transportation tools in mines - flatbed truck, can solve the problems of inability to move large equipment as a whole, carrying capacity and geometric size limit of the car body, etc., to shorten production preparation time and reduce labor intensity. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

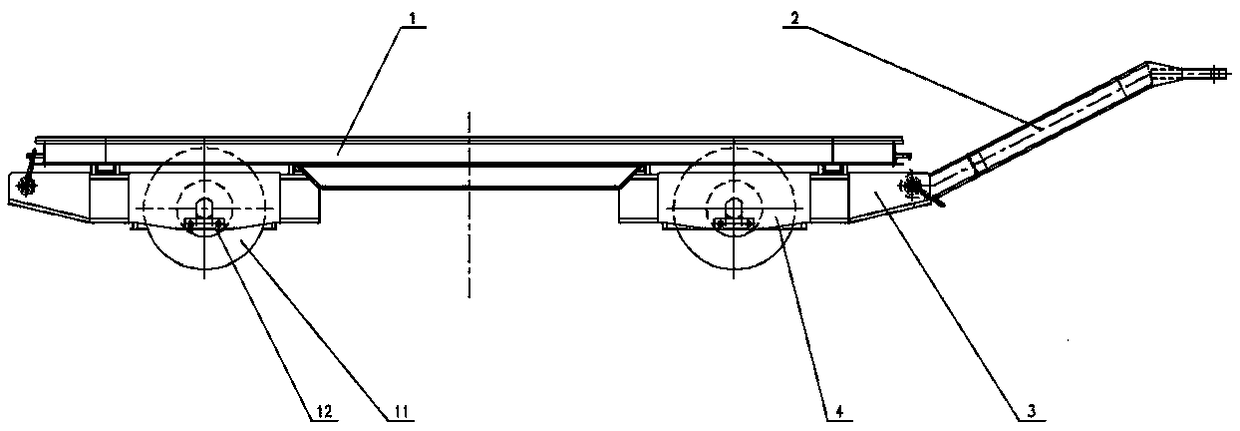

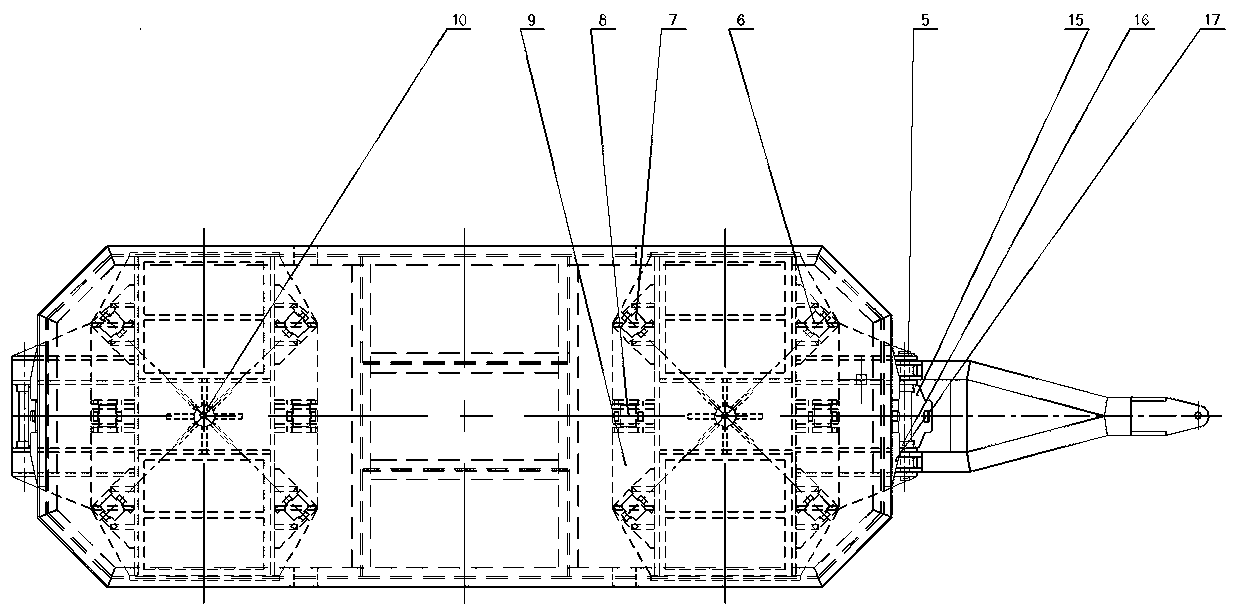

[0040] The ultra-low and heavy-duty two-way traction rubber-tyred flatbed vehicle is composed of a front wheel assembly, a rear wheel assembly, a flatbed 1 supported on the front wheel assembly and the rear wheel assembly, and a traction triangular mop 2. The front wheel assembly and the rear wheel The assembly structures are the same, and are distributed symmetrically with the center line of the plate 1;

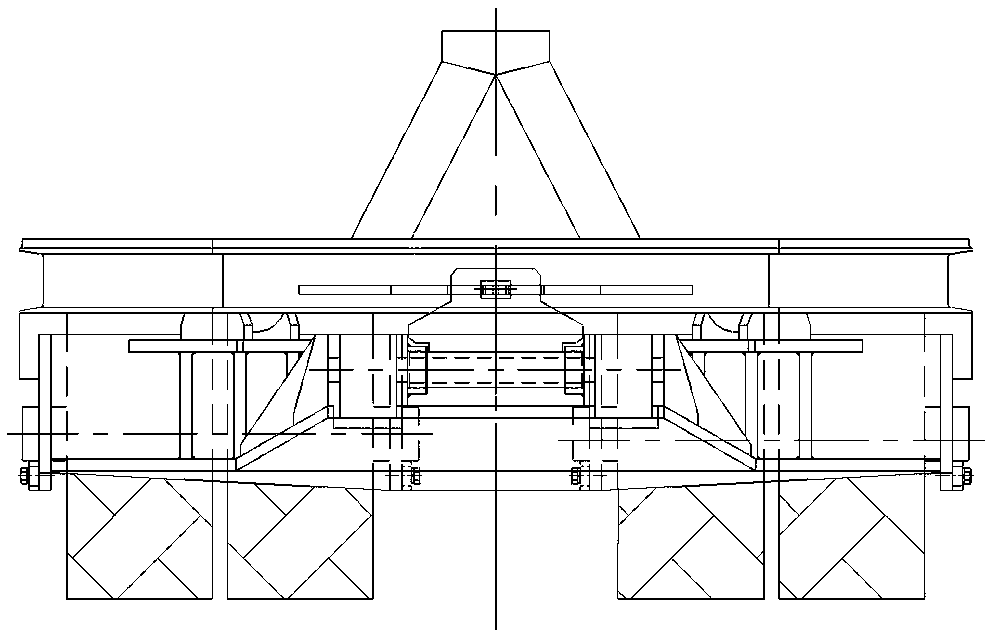

[0041] The front wheel assembly includes a traction frame 3, a carrier frame 4, rubber wheels 11, a carrier rib plate 9, a left roller assembly 7, a right roller assembly 6, a middle roller assembly 8, and a steering shaft assembly 10;

[0042] The traction frame 3 includes four traction plates 3-1 with the same shape. The traction plate 3-1 is composed of a right-angled trapezoidal plate at the front and a rectangular plate extending backward from the lower bottom edge of the right-angled trapezoidal plate. The four traction plates 3- The oblique waist surface of the right-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com