Overturning plate type refrigerator inner container horizontal corner line riveting mechanism

A technology of freezer liner and riveting mechanism, which is applied to other household appliances, household appliances, applications, etc., can solve problems such as low yield and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

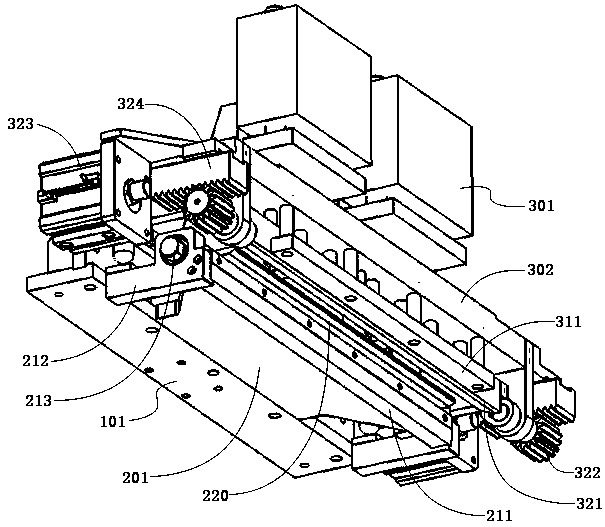

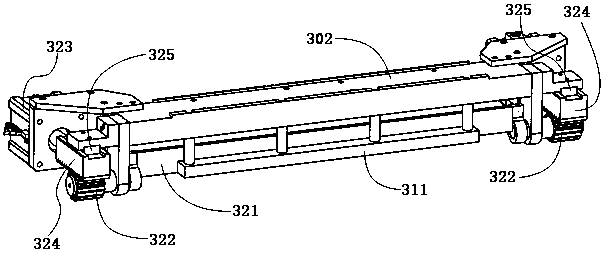

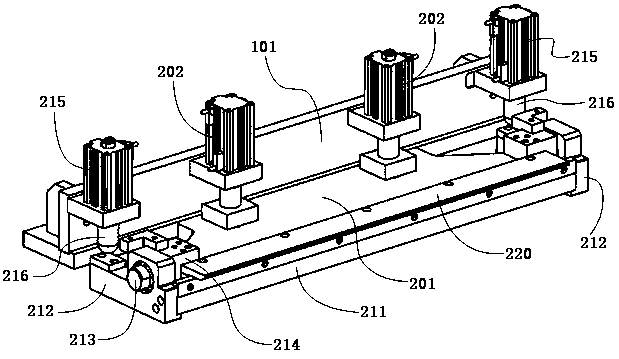

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a riveting mechanism for the horizontal corner line of the inner container of a flap-type refrigerator includes a straight-side clamping mechanism, a straight-side pressing plate bending mechanism and a bracket 101 . The straight side jaw mechanism and the straight side platen bending mechanism are installed on the bracket 101 .

[0021] The straight side platen bending mechanism includes a straight side platen mold bar 311 , a straight side bending mold bar 321 and a straight side drive frame 302 . A drive cylinder 301 is installed above the straight edge drive frame 302 . The straight side driving frame 302 is connected to the piston of the driving cylinder 301 , and enables the straight side driving frame 302 to be lifted up and down driven by the driving cylinder 301 . The straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com