Stubble cleaning assembly of corn harvester

A corn harvester and stubble removal technology, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of large space occupation, high power consumption, long straw, etc., and achieves easy assembly, small occupation space, and reduced The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

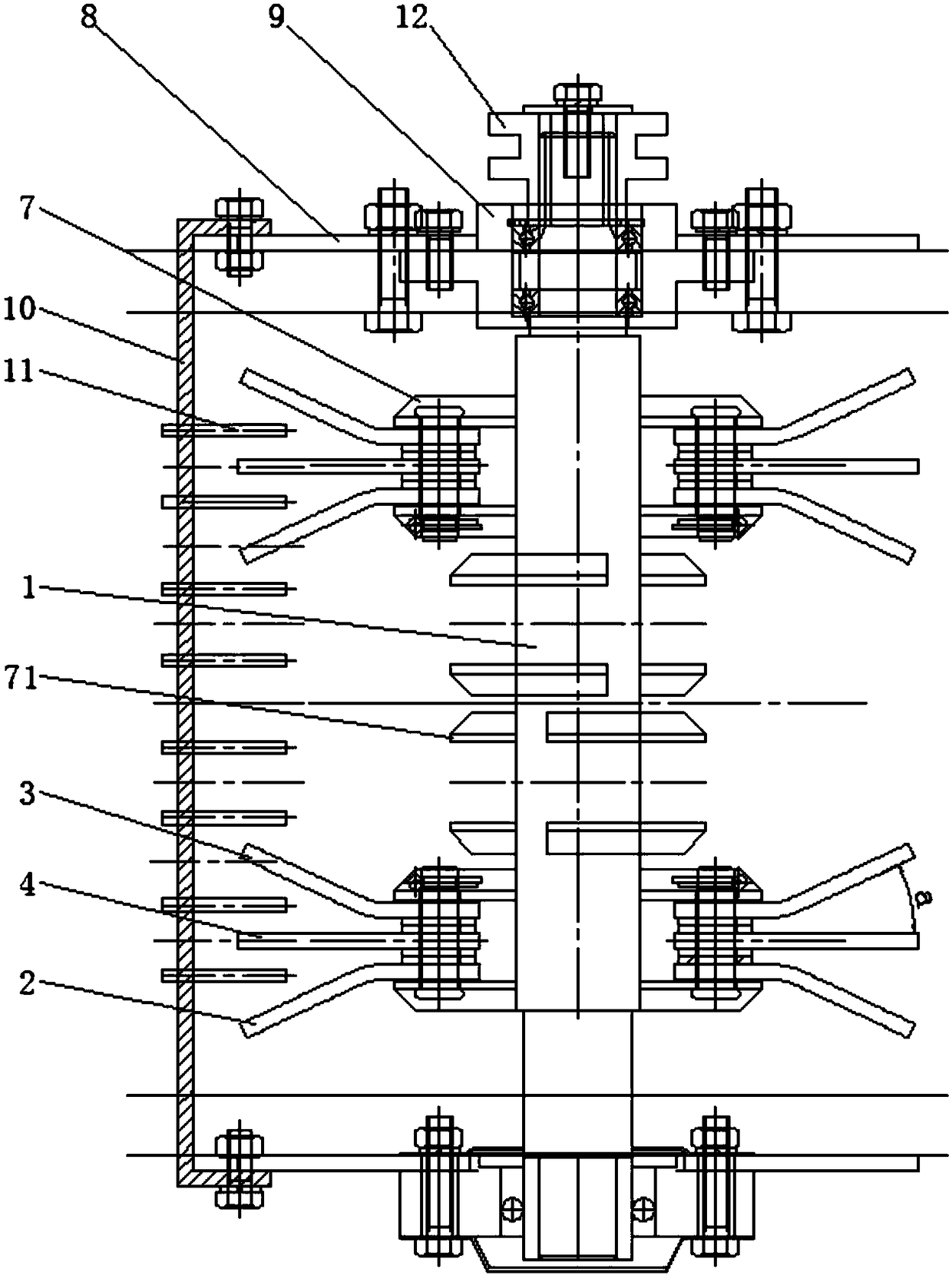

[0022] Such as figure 1 As shown, two vertical plates 8 on the left and right are fixedly installed on the frame, and these two vertical plates 8 are parallel to each other. The moving knife shaft 1 passes through two vertical plates 8 vertically, the left end of the moving knife shaft 1 is supported on the left vertical plate 8 through a bearing and a bearing seat 9, and the right end of the moving knife shaft 1 is supported by another set of bearings and a bearing seat 9 On a vertical board 8 on the right side. One end of the moving knife shaft 1 is fitted with a duplex sprocket 12, and the duplex sprocket 12 is connected with the engine or the gearbox of the corn harvester through a chain transmission mechanism.

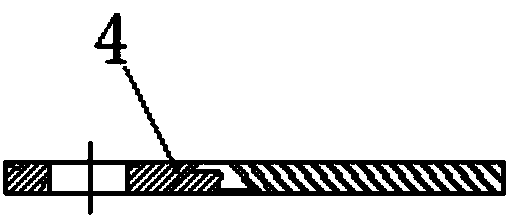

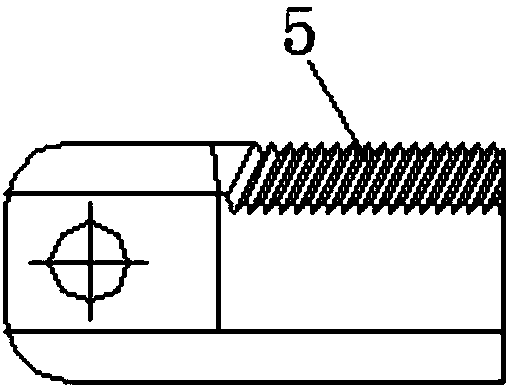

[0023] Such as Figure 1 to Figure 5 As shown, a plurality of throwing blade units are arranged along its axial direction on the moving knife...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com