Vacuum perfusion assisting device and vacuum perfusion process

A technology of vacuum infusion and auxiliary device, applied in the field of blade manufacturing, can solve the problems of slow heating speed, waste of labor efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Like reference numerals refer to like parts throughout.

[0027] According to an embodiment of the present invention, a vacuum infusion auxiliary device is provided, which is used to seal the material laying area after laying the laying layer (for example, glass fiber cloth layer) and before vacuuming when manufacturing the blade, so as to A closed environment is formed to facilitate subsequent vacuuming and resin infusion operations.

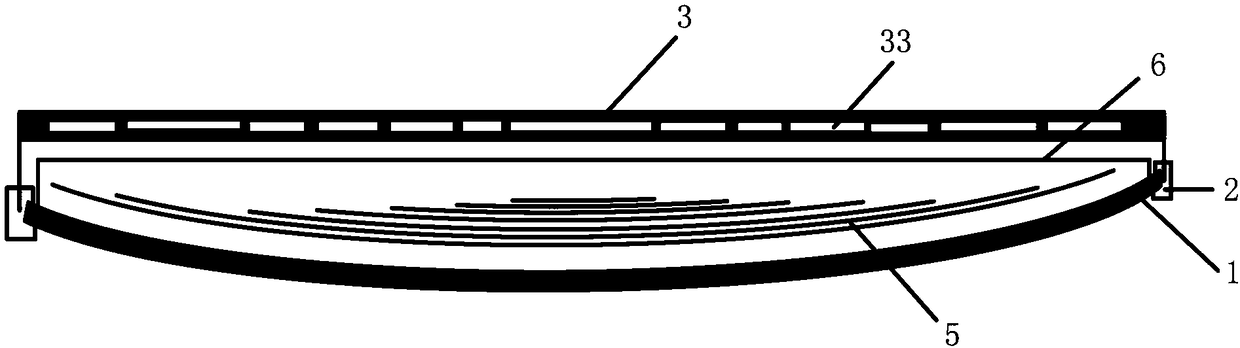

[0028] The vacuum infusion auxiliary device can be placed on the mold 1 after laying the laying layer or glass fiber cloth layer 5 on the mold 1, and can completely cover the material laying area. The vacuum infusion auxiliary device provided by the present invention can be applied to any blade part molding, for example, blade shell molding, main spar molding or web or other parts molding and so on.

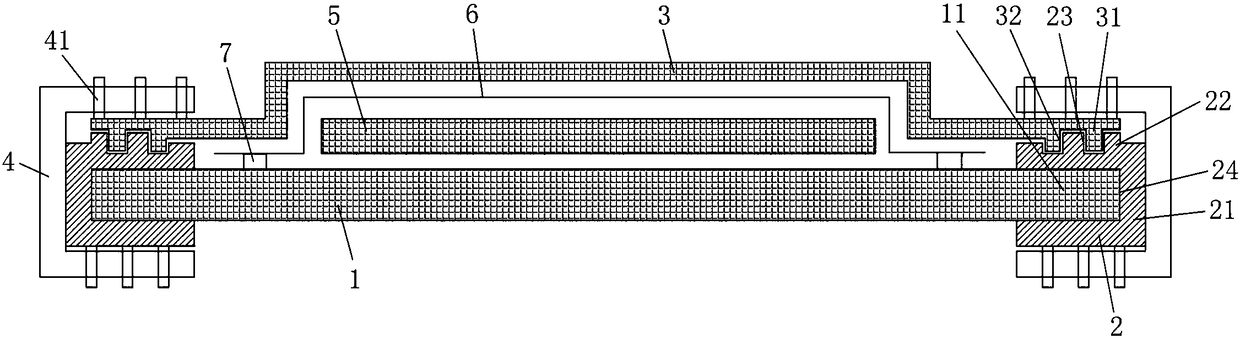

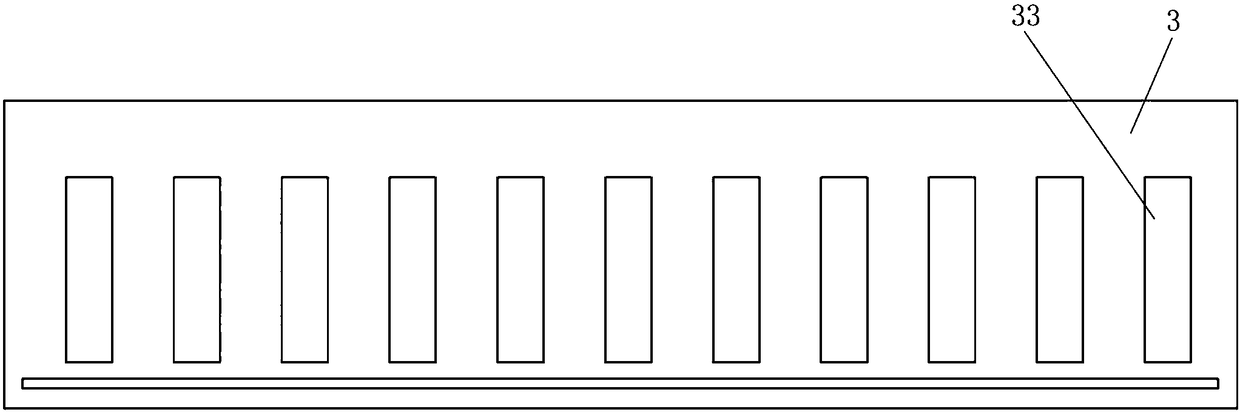

[0029] figure 1 is a schematic structural view of a vacuum perfusion assisting device according to an embodiment of the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com