Automatic generation method for busbar parametrized material bill and process route

A bill of materials and process route technology, applied in the field of IT information, can solve the problem of data being unable to be effectively connected, and achieve the effect of improving efficiency and on-time delivery rate, avoiding manual intervention, and reducing design links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

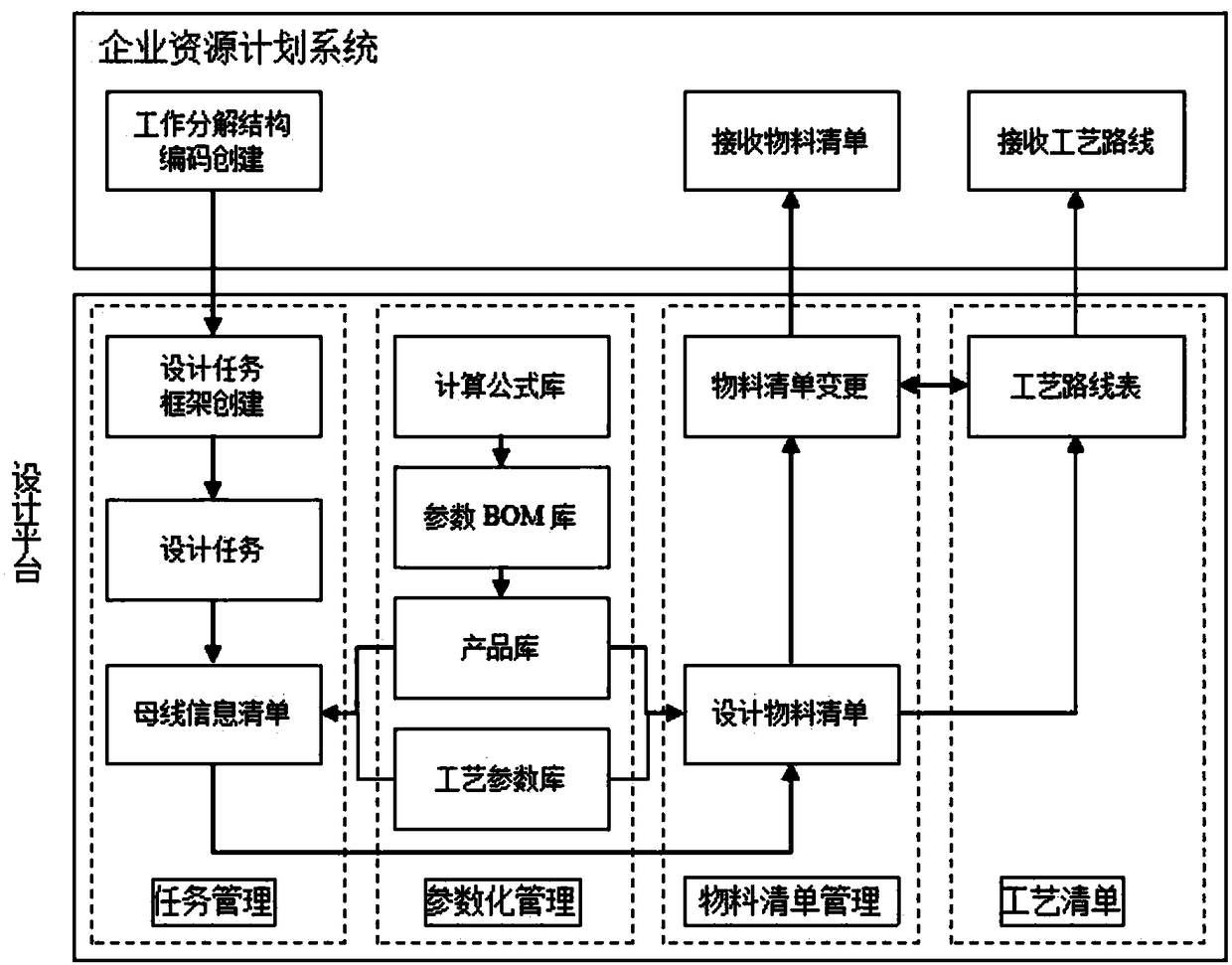

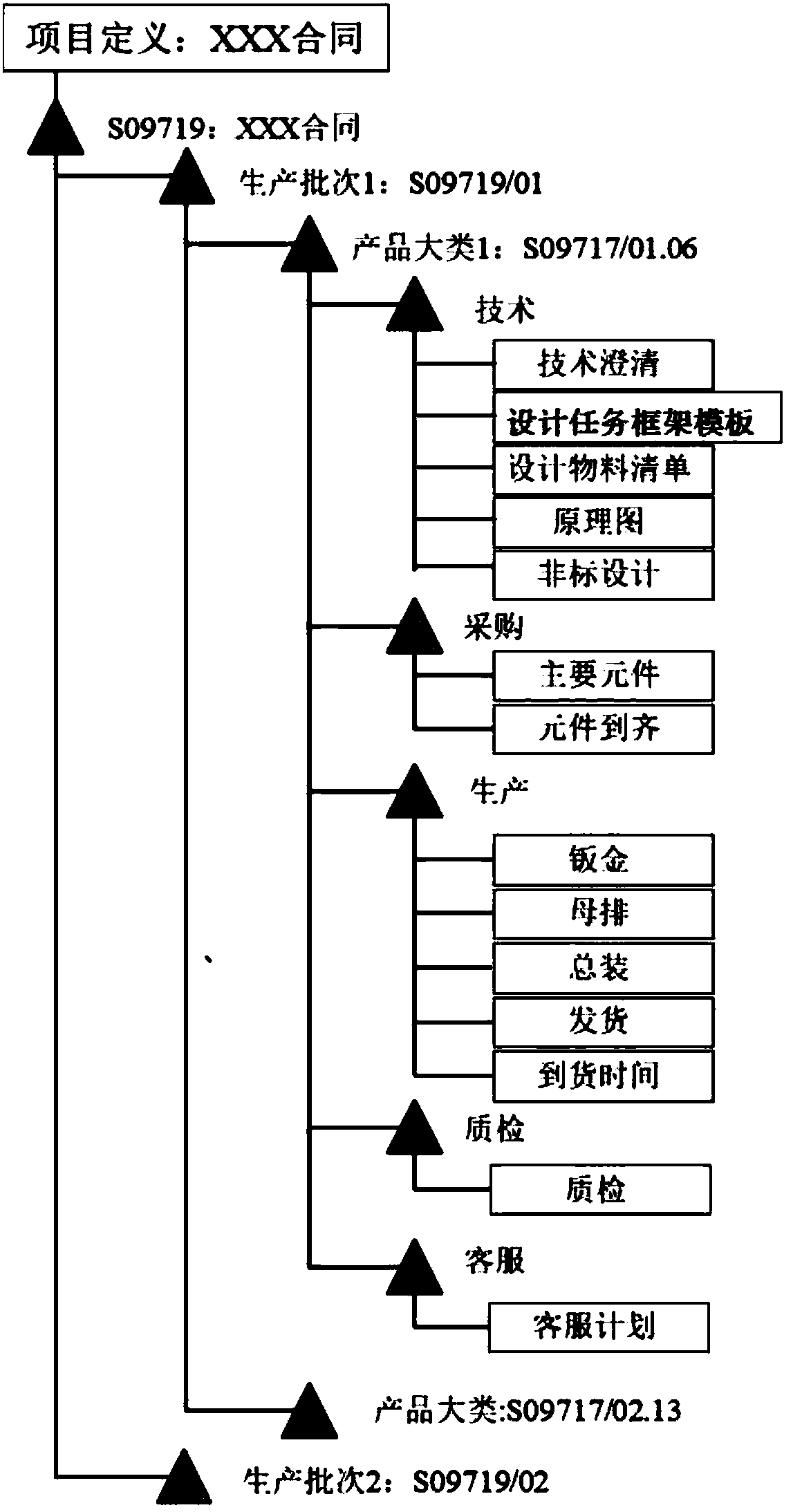

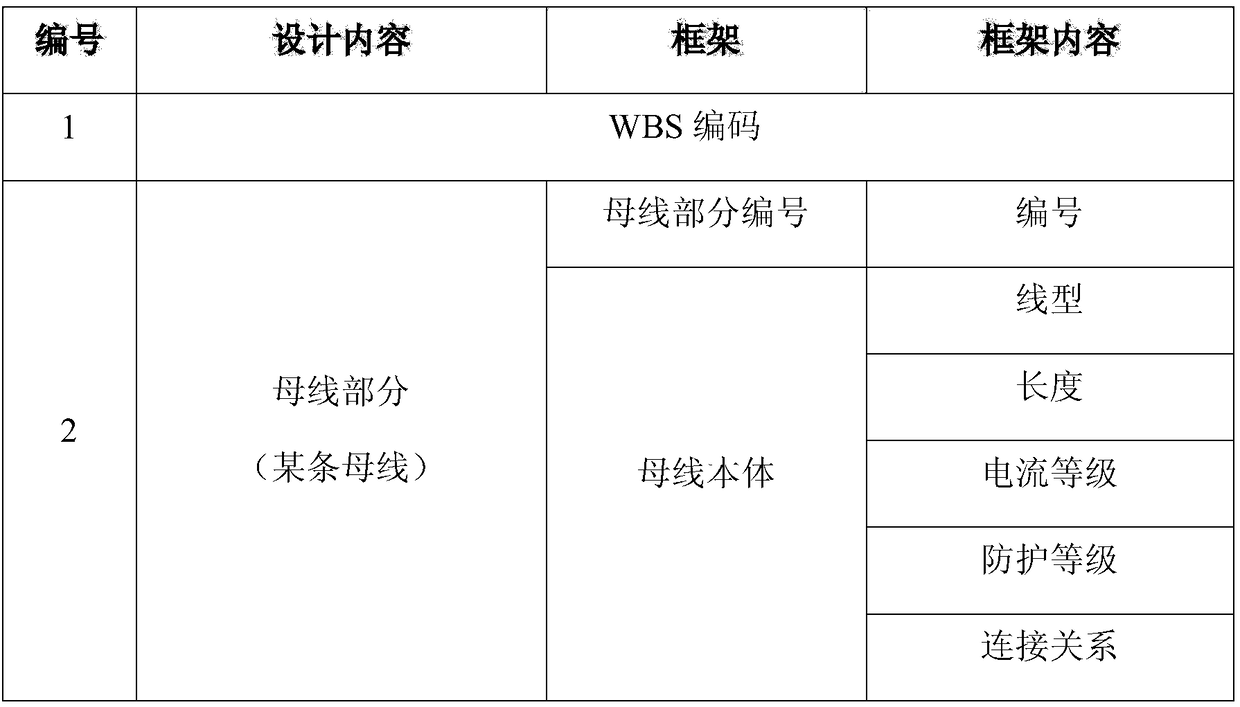

[0018] An embodiment of the present invention is a method for automatically generating bus parameterized BOM and process route, such as figure 1 with figure 2 As shown, it includes the following steps: 1) According to the design task framework template of the Work Breakdown Structure (WBS) in the busbar design and production process, fill in the content and create the design task framework; 2) According to the design task framework, substitute the design bill of materials Calculate the logical formula corresponding to the item to generate the design bill of materials for the busbar; 3) Substituting the design bill of materials into the calculation of the process route formula to generate the process route.

[0019] Connect the enterprise resource planning system with the design platform in series, support receiving the sales order work breakdown structure number delivered by the enterprise resource planning system, and automatically generate the design task framework accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com