Adaptive control cabinet

An adaptive control cabinet technology, applied in the direction of cooling/ventilation/heating transformation, using gaseous coolant for modification, etc., can solve the problems that ordinary control cabinets cannot judge heat dissipation by themselves, so as to improve heat dissipation efficiency, save energy, enhance The effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further detailed explanation through specific implementation mode below:

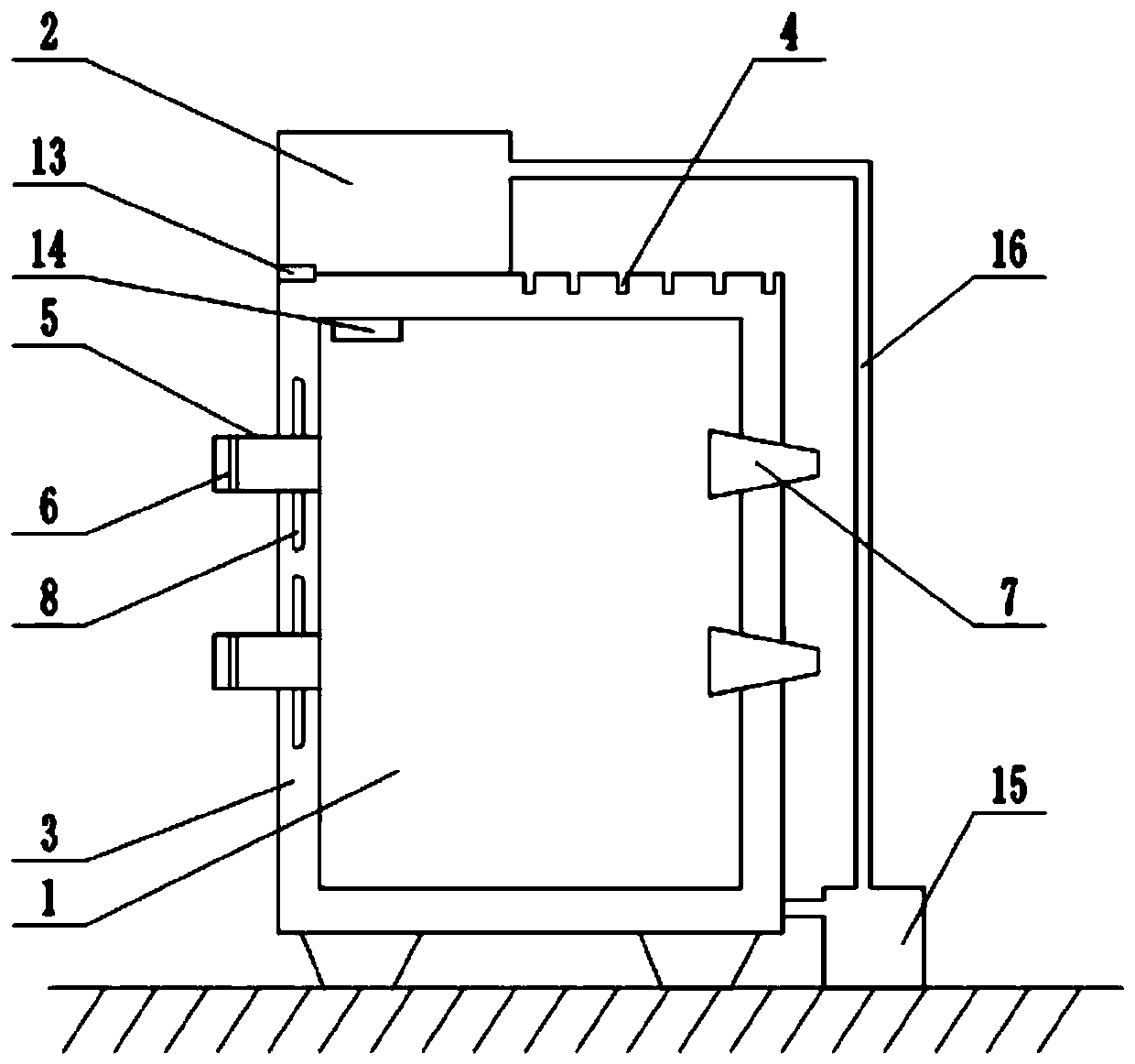

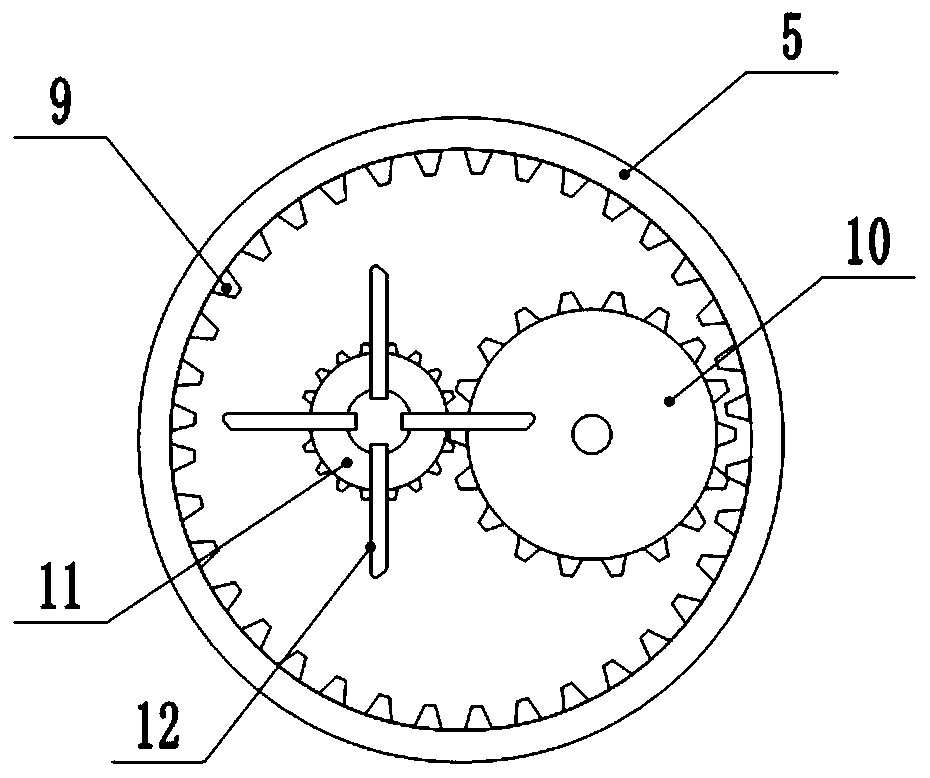

[0016] The reference signs in the drawings of the specification include: cabinet body 1, water tank 2, gap layer 3, vent hole 4, air inlet pipe 5, dustproof net 6, conical pipe 7, rotating blade 8, ring gear 9, first Gear 10, second gear 11, fan 12, control valve 13, temperature sensor 14, water pump 15, water pipe 16.

[0017] This embodiment is basically as figure 1 As shown, the adaptive control cabinet includes a cabinet body 1 and a water tank 2 fixedly connected to the cabinet body 1. The cabinet body 1 includes an inner wall and an outer wall, and a gap layer 3 is formed between the inner wall and the outer wall. The top of the outer wall of the cabinet body 1 is provided with a number of ventilation holes 4, and the side wall of the cabinet body 1 is rotatably connected with two air inlet pipes 5, the air inlet pipes 5 are set through the inner wall and the outer wall, and the inner bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com