Green remanufacture-based heavy machine tool module partition method

A heavy-duty machine tool and remanufacturing technology, applied in computer parts, character and pattern recognition, special data processing applications, etc., can solve the problems of high manufacturing energy consumption, high price, and many consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

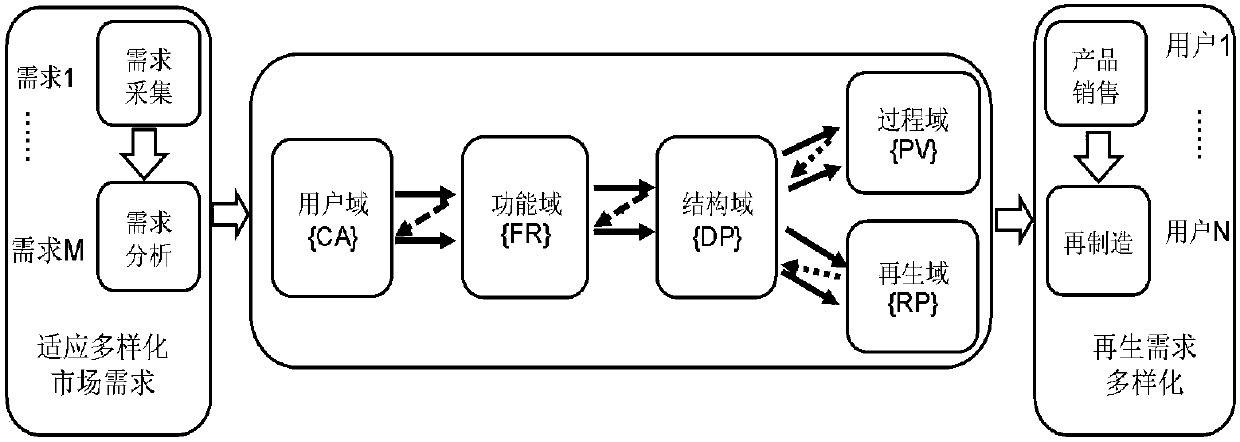

Method used

Image

Examples

Embodiment Construction

[0089] In order to realize the module division of heavy-duty machine tools for remanufacturing, the present invention takes a certain type of heavy-duty gantry milling machine as an example to verify the above-mentioned module division method.

[0090] The specific implementation steps are as follows:

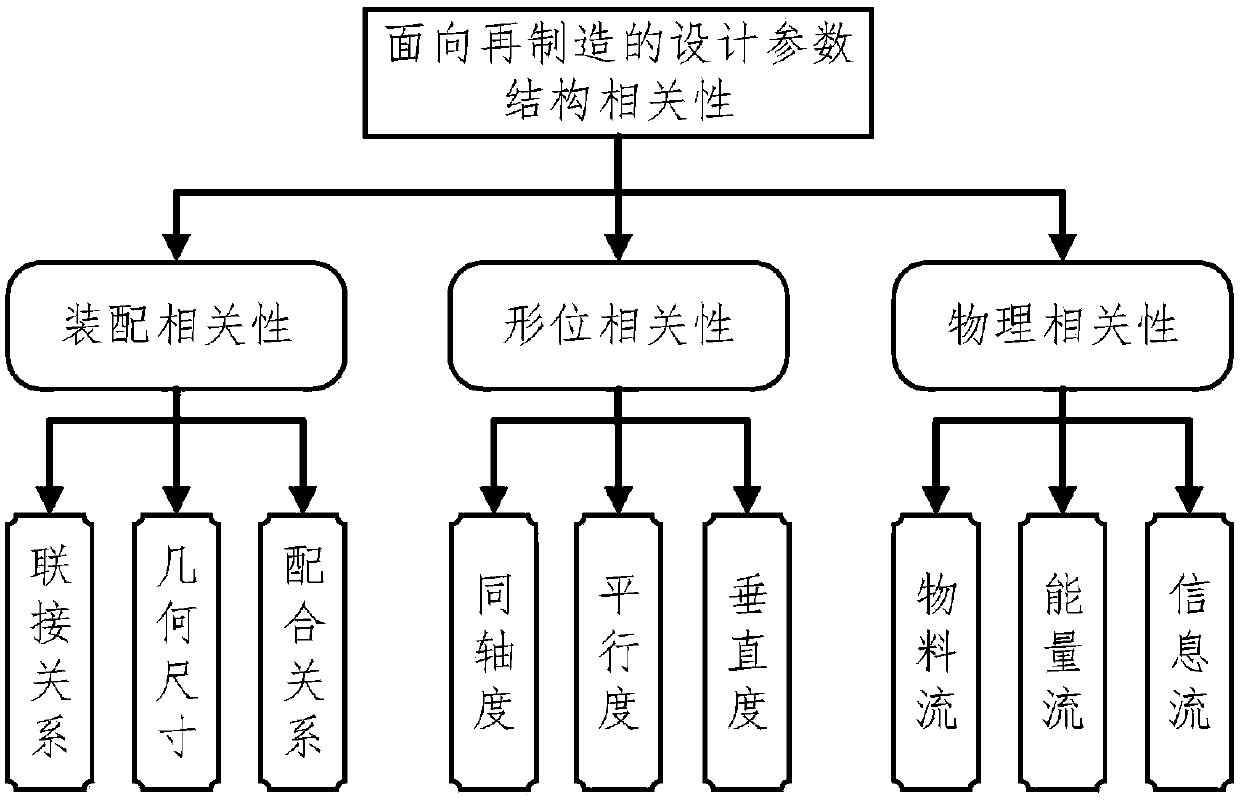

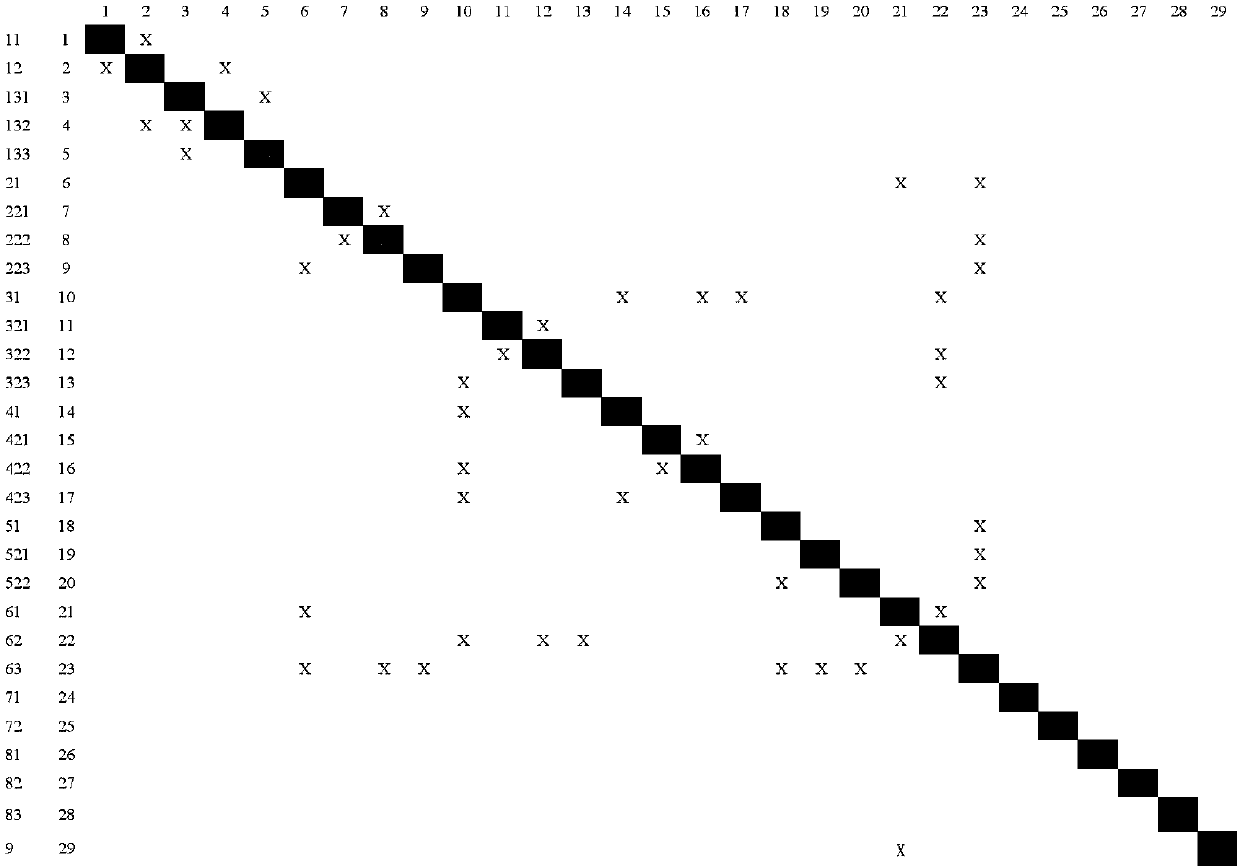

[0091] Step 1 Establish the remanufacturing correlation design structure matrix of heavy machine tool design parameters

[0092] According to the basic principle of axiomatic design theory, the present invention expresses the relationship between the design parameters of the heavy machine tool in the form of matrix; through the quantitative analysis of the design matrix and the actual structure of the heavy machine tool, the correlation matrix of the design parameters of the heavy machine tool is established. Step 1.1 Machine tool structure diagram

[0093] In this study, the 3D structural model of the heavy-duty gantry milling machine.

[0094] Step 1.2 Establish the Remanufac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com