Three-dimensional adjusting device

A technology of three-dimensional adjustment and three-dimensional scanning, which can be used in measuring devices, optical devices, cameras, etc., and can solve problems such as difficult correction and changes in camera angles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

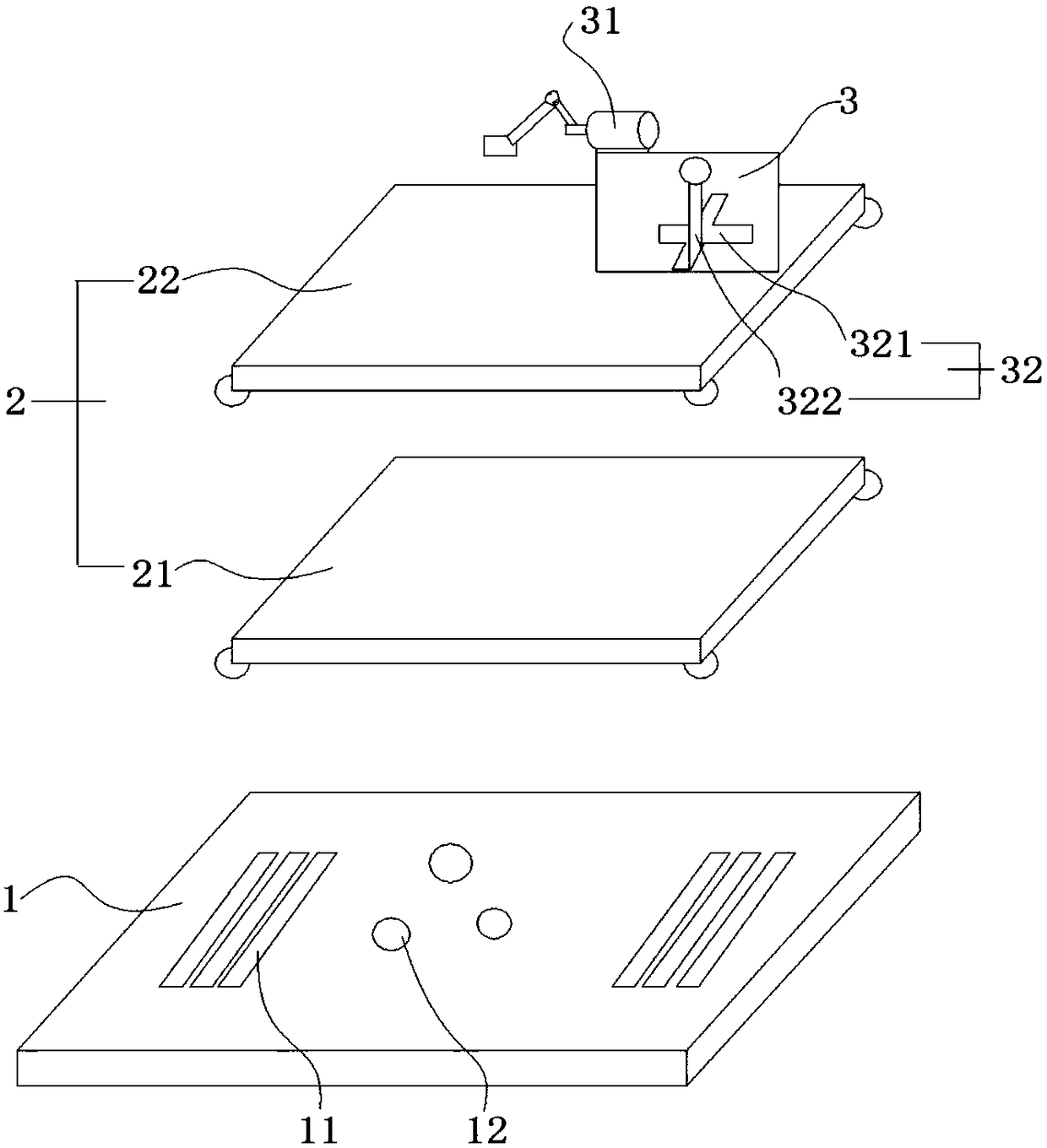

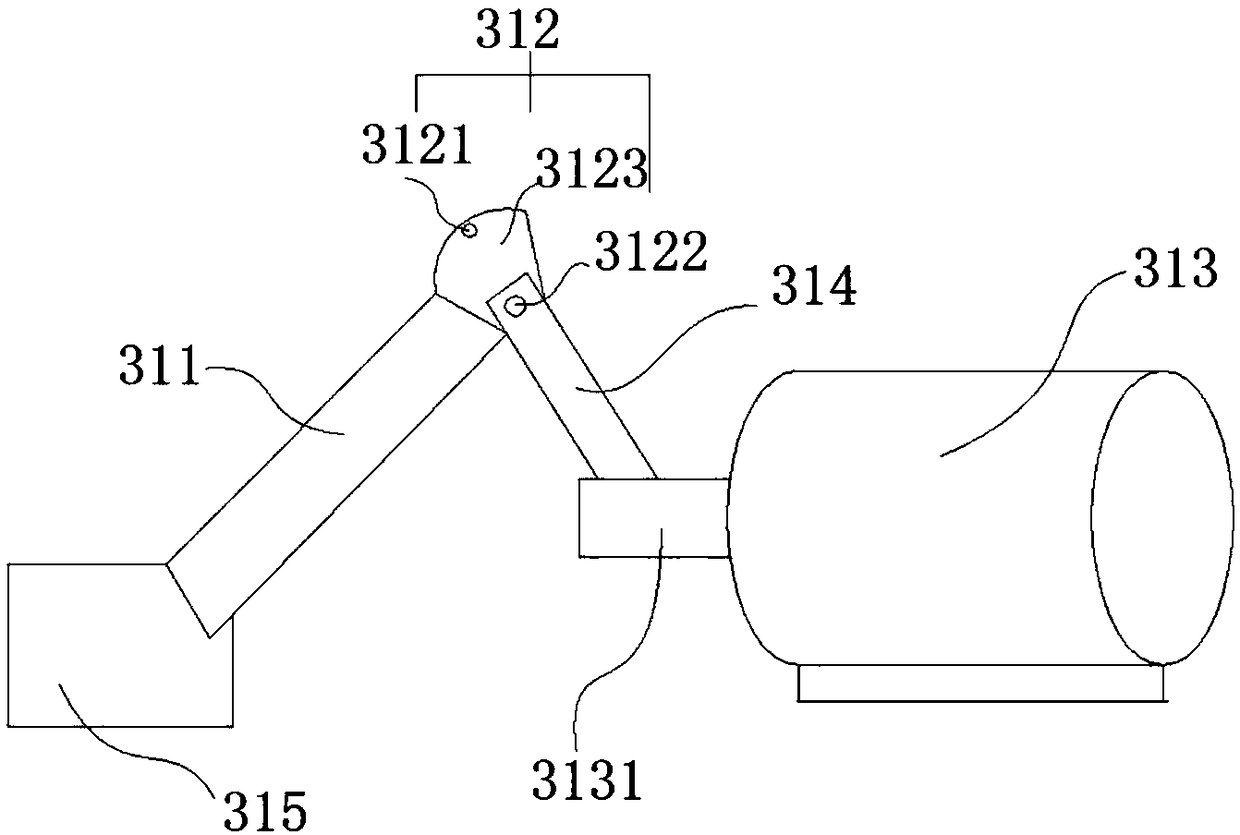

[0020] See figure 1 , the three-dimensional adjustment device in a preferred embodiment of the present invention includes a base plate 1, a camera base 2 arranged on the base plate 1, a fine-tuning structure arranged on the camera base 2, the base plate 1 and the camera A slide rail (not shown) for moving the camera base 2 and a drive member (not shown) for driving the slide rail are arranged between the bases 2, and the fine-tuning mechanism includes a rotation unit 31 and an adjustment unit 32, The rotation unit 31 is connected with the adjustment unit 32 in signal. In this embodiment, the center of the bottom plate 1 is provided with a bottom grating screw hole 12 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com