A variable stiffness flexible manipulator

A flexible manipulator and variable stiffness technology, applied in manipulators, claw arms, manufacturing tools, etc., can solve problems such as high cost and limited application scope, and achieve the effect of simple adjustment, easy control, and a large range of variable stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

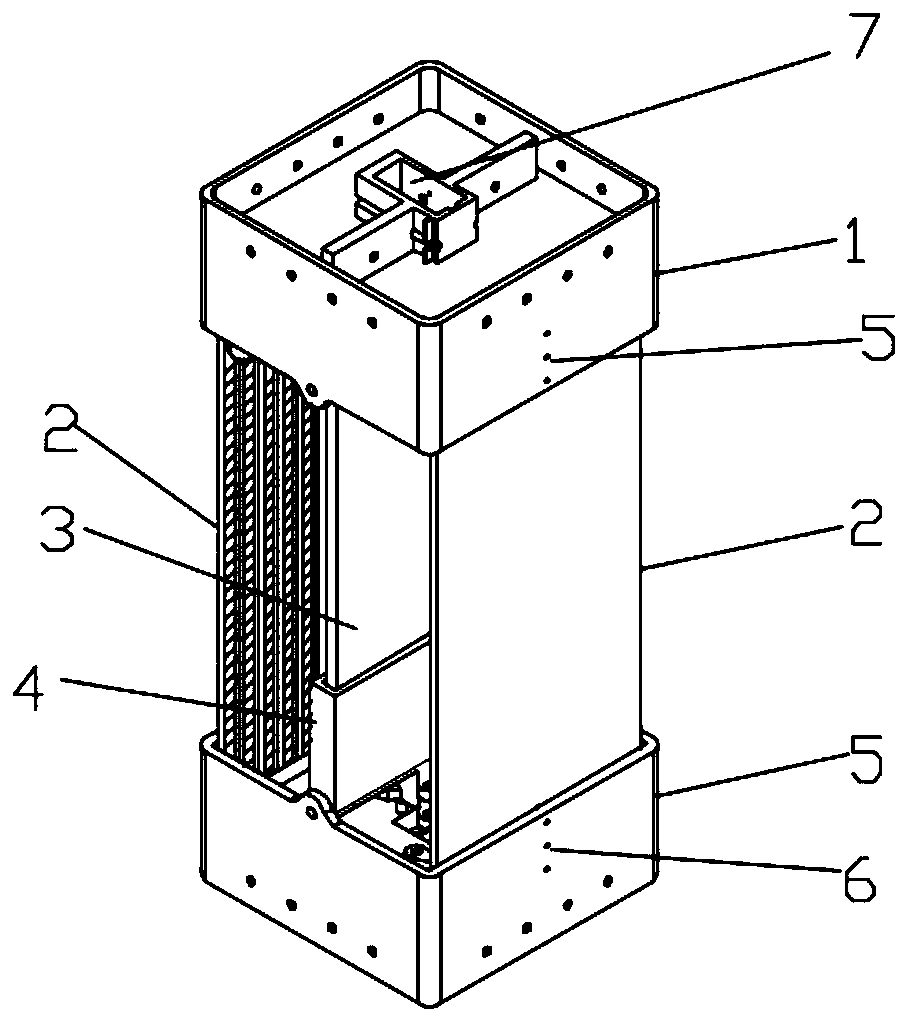

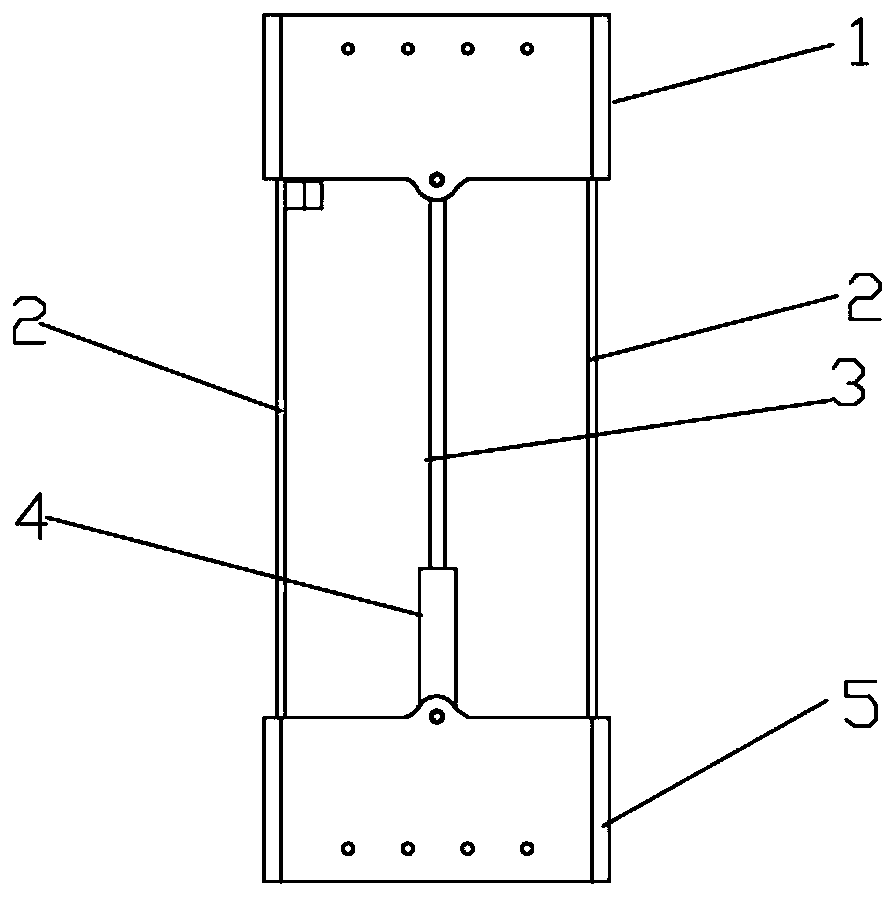

[0025] The variable stiffness flexible mechanical arm proposed by the present invention has a structure such as figure 1 As shown, it includes a top seat 1, two variable rigidity support plates 2, a central support plate 3, a long slot 4, a base 5, two cross-shaped driving parts 8 and eight connecting rods 18 (19, 20, 21), Such as Figure 7 with Figure 8 shown in . The upper ends of the two variable stiffness support plates 2 are fixed on two sides of the top base 1 , and the lower ends of the two variable stiffness support plates 2 are fixed on the corresponding two sides of the base 5 . The central support plate 3 is placed in the middle of the two variable stiffness support plates 2, the upper end of the central support plate is relatively fixed to the top seat, the long slot 4 is placed in the middle of the base, and the lower end of the central support plate 2 extends into the long slot In 4, similar to the sleeve structure, it plays a supporting role and connects the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com