Variable-frequency control constant-pressure air compression system for printing and dyeing textile equipment

A textile printing and dyeing, frequency conversion control technology, applied in the field of textile printing and dyeing, can solve the problems of high energy consumption, high operating power of the air compressor, and power loss in the air compression system of constant air pressure control, so as to achieve less power loss, avoid impact, and improve energy efficiency. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

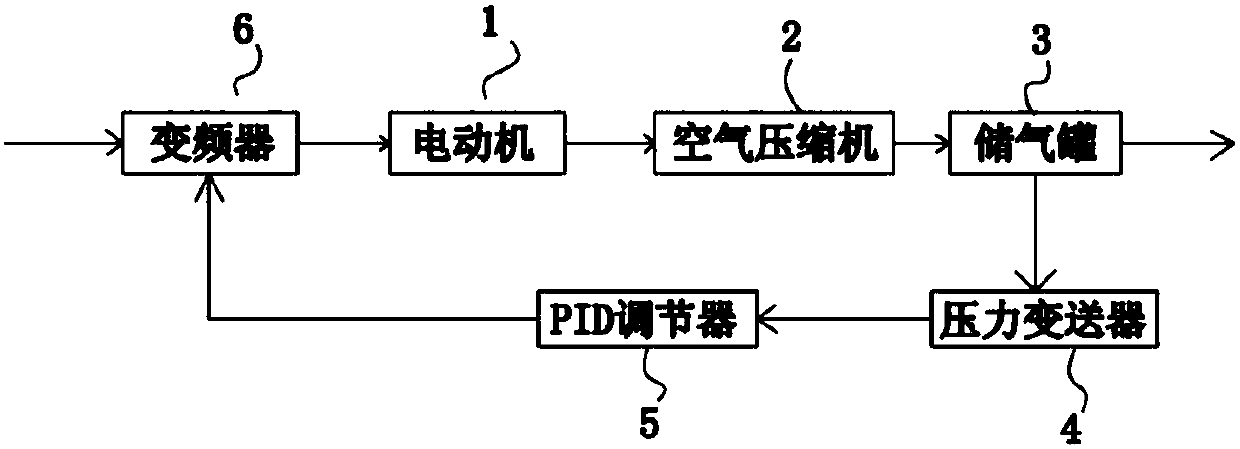

[0012] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

[0013] Such as figure 1 The shown air compression system for textile printing and dyeing equipment of the present invention is controlled by frequency conversion and constant pressure, including a motor 1, an air compressor 2, an air storage tank 3, a pressure transmitter 4, a PID regulator 5 and a frequency converter 6, and the motor 1 is a mouse Cage-type induction motor, the motor 1 is connected to the air compressor 2, the air compressor 2 is connected to the air storage tank 3, the exhaust end of the air storage tank 3 is connected to the gas device of the textile printing and dyeing equipment, and the pressure transmitter 4 is installed on On the gas storage tank 3, the frequency converter 6 is electrically connected to the motor 1 of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com