Hoisting mechanism automatic rope-arranging device

A hoisting mechanism and automatic rowing technology, applied in the direction of hoisting device, mainspring mechanism, etc., can solve the problems of shortening the service life of the wire rope, wrapping at one end of the drum, and the wire rope running out, preventing kinks and achieving reasonable structural design. , the effect of small radial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

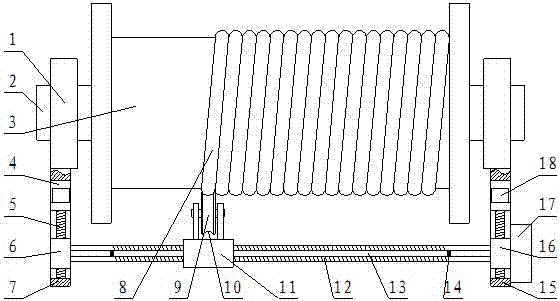

[0014] Such as figure 1 As shown, an automatic rope-rowing device for a hoisting mechanism includes two hinge seats 1, a main shaft 2 is arranged between the two hinge seats 1, a drum 3 is arranged on the main shaft 2, and the A wire rope 8 is wound on the drum 3, and the end of the wire rope 8 on the drum 3 is set in the rope groove 10 on the outer circumferential surface of the guide wheel 9, and the guide wheel 9 is rotated and arranged on the guide seat 11 Above, the guide seat 11 is connected to the threaded rod A12 through a threaded connection, the threaded rod A12 is arranged parallel to the main shaft 2, and the upper part of the threaded rod A12 is provided with a limit rod 13 parallel to it. Sliding connection between the rod 13 and the guide seat 11, the two ends of the limit rod 13 and the threaded rod A12 are respectively connected on the slider A6 and the slider B16, and the threaded rod A12 is connected with the slider A6 and the slider Rotation connection bet...

Embodiment 2

[0017] Such as figure 1 As shown, an automatic rope-rowing device for a hoisting mechanism includes two hinge seats 1, a main shaft 2 is arranged between the two hinge seats 1, a drum 3 is arranged on the main shaft 2, and the A wire rope 8 is wound on the drum 3, and the end of the wire rope 8 on the drum 3 is set in the rope groove 10 on the outer circumferential surface of the guide wheel 9, and the guide wheel 9 is rotated and arranged on the guide seat 11 Above, the guide seat 11 is connected to the threaded rod A12 through a threaded connection, the threaded rod A12 is arranged parallel to the main shaft 2, and the upper part of the threaded rod A12 is provided with a limit rod 13 parallel to it. Sliding connection between the rod 13 and the guide seat 11, the two ends of the limit rod 13 and the threaded rod A12 are respectively connected on the slider A6 and the slider B16, and the threaded rod A12 is connected with the slider A6 and the slider Rotation connection bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com