Method for designing asymmetric hull outer panel tyre frame

A hull shell plate and design method technology, applied in ship design, ship construction, ship parts, etc., can solve problems such as unsuitable asymmetric hulls, save manpower and material resources, shorten cycle time, and ensure smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

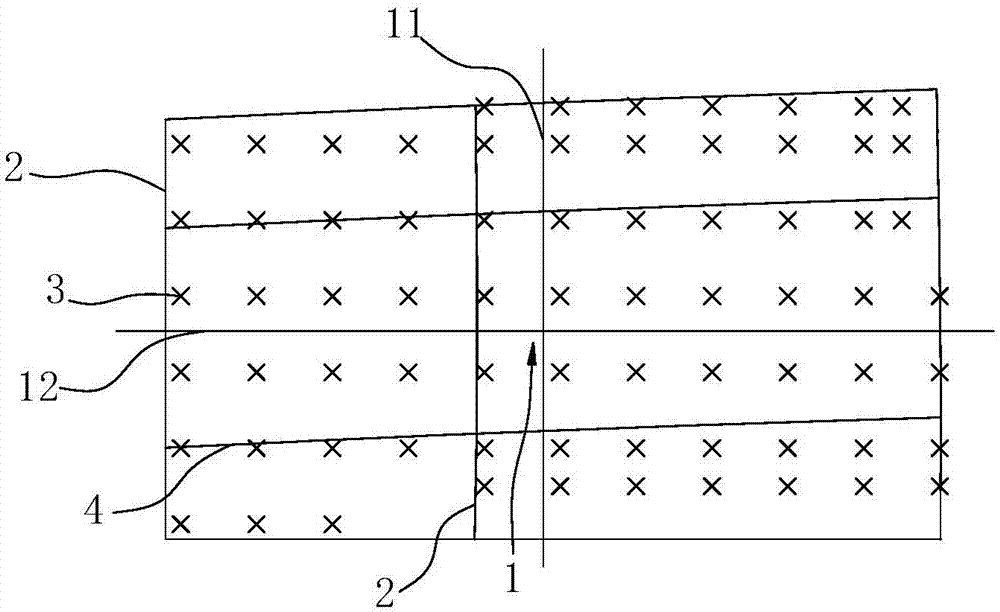

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0027] Such as figure 1 As shown, in this embodiment, a method for designing an asymmetrical hull frame of the present invention includes the following steps:

[0028] Step S10: Establish the models of the left outer plate seam and the left frame in the asymmetrical molded line area on the segment respectively, obtain the left outer plate seam model and the left frame model, and establish the asymmetrical molded line respectively The model of the outer plate seam on the right side of the area and the right frame is obtained, and the model of the right outer plate seam and the right frame are obtained;

[0029] Step S20: Generate the left outer panel model according to the left outer panel joint model and the left outer panel molding line respectively, and combine the left outer panel model and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com