Adjustable novel light inspection station

A light inspection table and adjustable technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve problems such as inspection omissions, lower product qualification rate, and health hazards, so as to relieve cervical pressure and avoid omissions , detection orderly and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

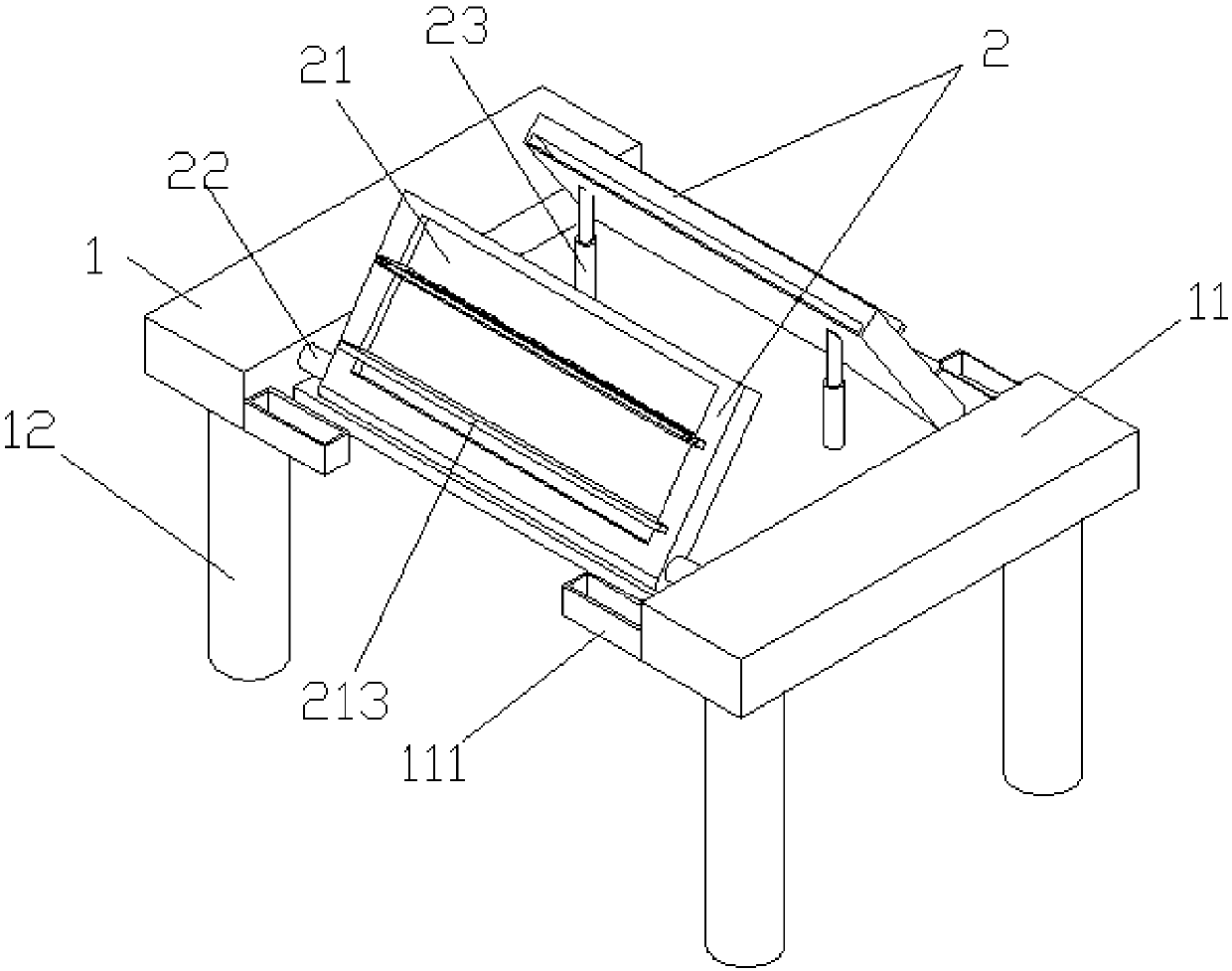

[0024] This embodiment provides a capsule light inspection platform, which includes an inspection platform 1. The inspection platform 1 includes a support plate and support platforms 11 fixed on both sides of the support plate. There are several supporting columns 12, so that the test table 1 can be placed in corresponding positions.

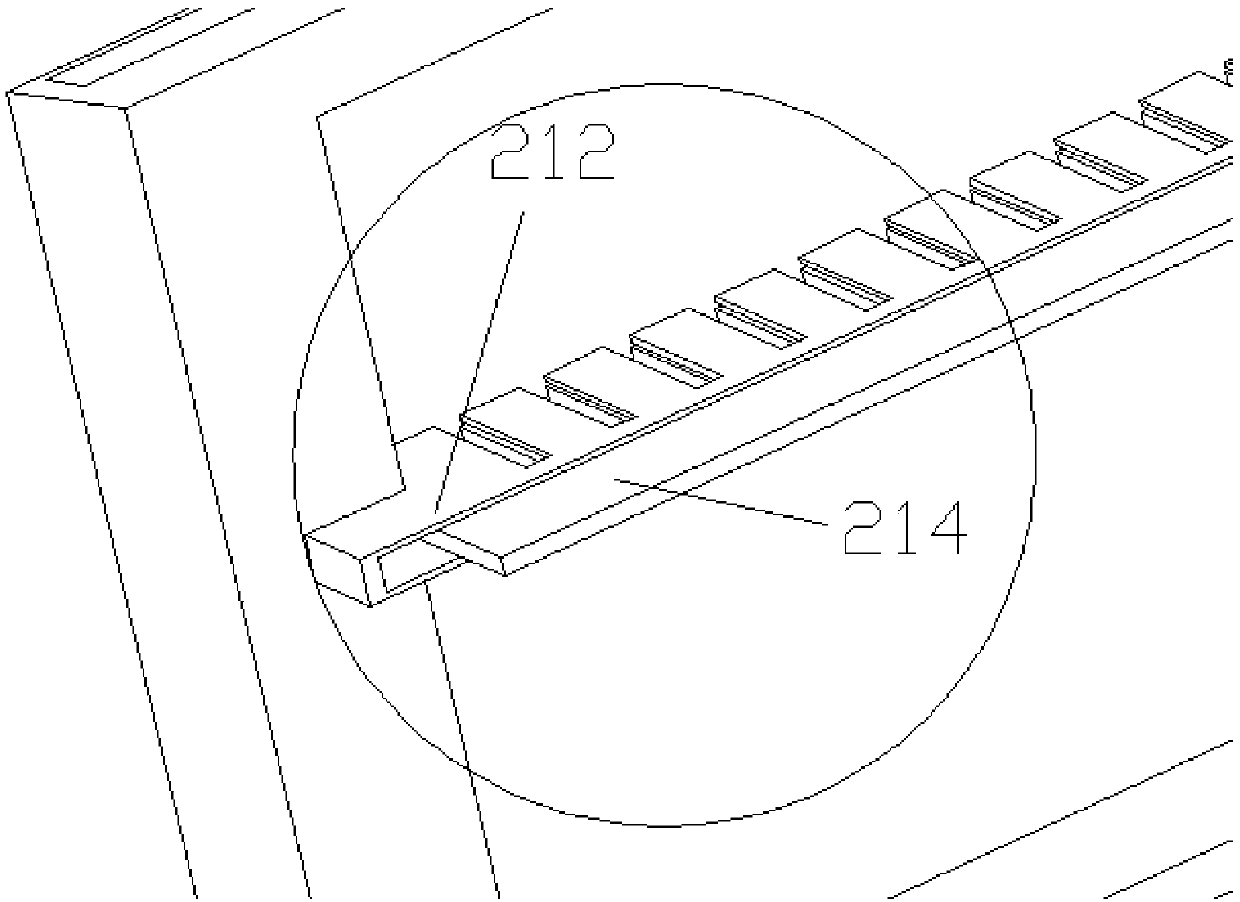

[0025] Two symmetrically distributed inspection units 2 are arranged on the top of the support plate, and the inspection unit 2 includes a rectangular lamp housing 21, and a plurality of telescopic rods 22 arranged between the lamp housing 21 and the support board. Preferably, the telescopic The telescopic cylinder structure can be selected for the rod 22; the bottom of the telescopic rod 22 is fixedly connected to the support plate, and the top of the telescopic rod 22 is hinged to the lower surface of the lamp housing 21;

[0026] The bottom of the lamp housing 21 is rotated between the two support platforms 11 through a rotating shaft 23, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com