Telescopic conveyor

A conveyor and telescopic technology, which is applied in the field of telescopic conveyors, can solve the problems of low automation, large conveyor volume, and insufficient material inertia, etc., and achieve the effect of improving automation level, small size, and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

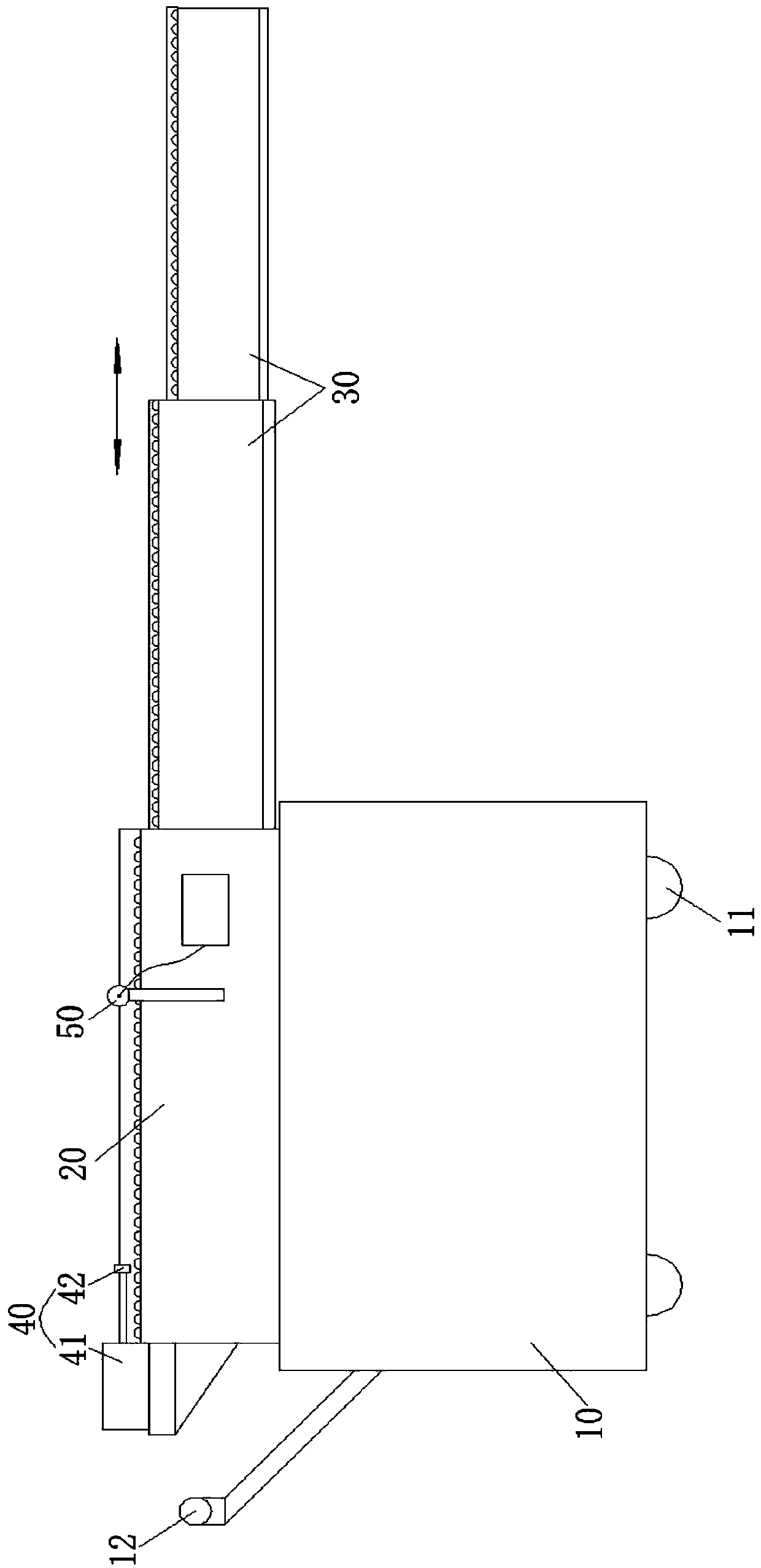

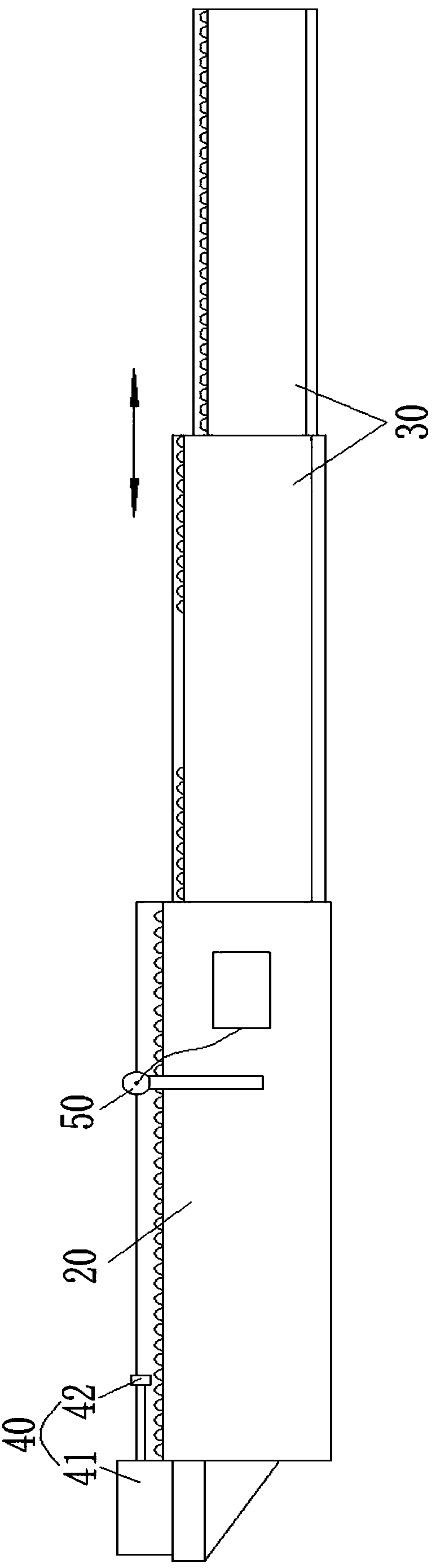

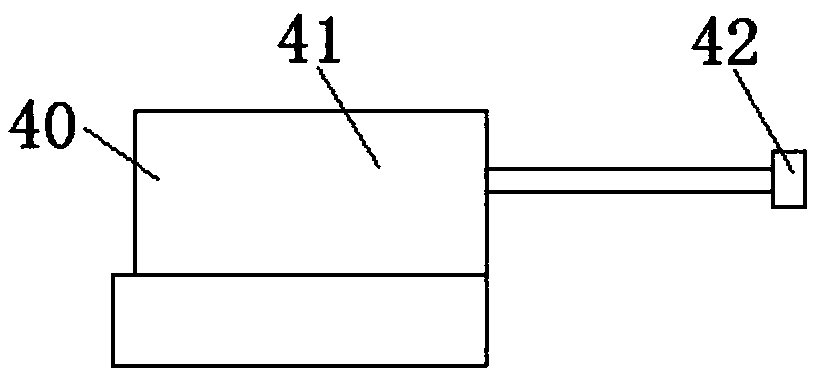

[0020] see figure 1 , figure 1 It is a structural schematic diagram of the telescopic conveyor of the present invention. The telescopic conveyor of the present invention comprises a support 10, a main transport frame 20 and a plurality of secondary transport frames 30; the main transport frame 20 is fixed on the support 10; one of the secondary transport frames 30 is slidably arranged on the On the main conveying frame 20, the plurality of adjacent secondary conveying frames 30 are slidingly connected to each other in turn; the side of the main conveying frame 20 is provided with a feeding assembly 40 for dialing materials and for counting materials. The count sensor 50.

[0021] Specifically, a transmission shaft is provided at the bottom of the support 10 , and rollers 11 are provided at both ends of the transmission shaft. In order to facilitate the transfer of the bracket 10 , in this embodiment, a push handle 12 is preferably provided on the bracket 10 , and the push h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com